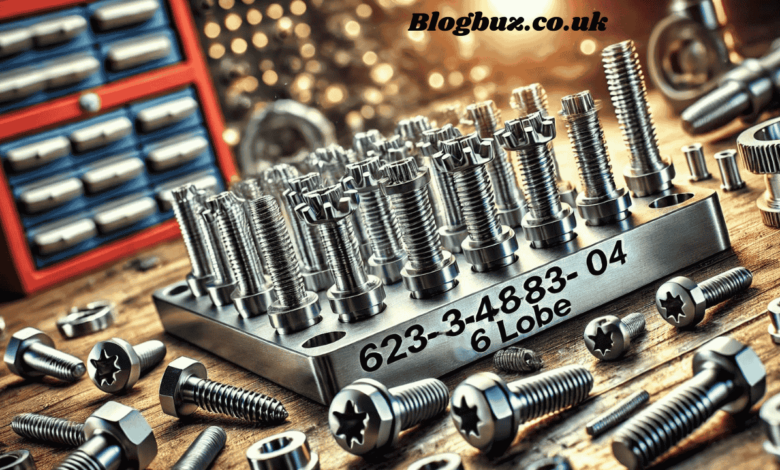

The Essential Guide to 623-483-04 6 Lobe Screw: Unleashing the Power of Precision Fastening

The 623-483-04 6 lobe screw, a staple in the fastening industry, offers unparalleled performance due to its unique design and robust material composition. This detailed overview discusses the features, applications, and best practices for using this screw effectively in various industrial settings.

Features of 623-483-04 6 Lobe Screw

The 623-483-04 screw is distinguished by its six-lobed star-shaped pattern, which allows for higher torque application without damaging the screw head. Crafted from A2-70 grade stainless steel, these screws are not only strong but also highly resistant to corrosion, making them ideal for use in challenging environments.

Design Advantages

The six-lobe design minimizes cam-out, the process where a screwdriver slips out of the screw head, thus enhancing the tool’s grip and reducing wear during installation. This feature ensures that the screws can be installed more securely and repeatedly, a critical factor in manufacturing and maintenance applications where precision is paramount.

Applications Across Various Industries

Due to their robust construction and versatile design, 623-483-04 screws find applications across a broad spectrum of industries:

- Automotive: Vibration resistance and durability are necessary in engine and chassis assembly.

- Electronics: Ideal for securing delicate components in devices due to their precise torque control.

- Aerospace: The screws’ strength and resistance to environmental extremes make them suitable for aircraft manufacturing.

- Construction: Though less common, their precise fastening capabilities are valued in specialized construction tasks.

Installation Tips

To maximize the performance of the 623-483-04 screws, proper installation is crucial:

- Tool Selection: Use the correct Torx driver to match the six-lobe design for optimal fit.

- Torque Settings: Apply the recommended torque to avoid over-tightening and potential damage.

- Pre-Drilling: For more rigid materials, pre-drilling can facilitate smoother installation and prevent material splitting.

Maintenance and Upkeep

Regular maintenance of these screws is necessary to ensure longevity and performance. This includes routine inspections for signs of wear or corrosion, proper cleaning after use, and applying anti-corrosive treatments in harsh environments.

Conclusion

The 623-483-04 6 lobe screw is more than just a fastener; it’s a critical component in the precise and durable assembly of various applications across multiple industries. Its innovative design and material quality make it an excellent alternative for professionals needing dependability and efficiency in their fastening solutions. Understanding its features and applications can significantly enhance the effectiveness of your projects, ensuring that every connection is secure and long-lasting.

FAQs About 623-483-04 6 Lobe Screw

What is a 623-483-04 6 lobe screw?

A 623-483-04 6 lobe screw, commonly referred to as a Torx screw, features a six-pointed star-shaped pattern allowing for higher torque application. This design helps prevent cam-out, enhancing the screw’s efficiency in high-torque applications.

What are the main advantages of using a 623-483-04 screw?

The primary advantages include improved torque transmission, reduced risk of damage to the screw head, enhanced holding power, and resistance to cam-out. These features make it highly reliable for demanding automotive, aerospace, and electronicsapplications.

What materials are 623-483-04 screws made from?

These screws are typically made from A2-70 grade stainless steel and are noted for their strength and corrosion resistance, making them excellent for both indoor and outdoor environments applications.

Where are 623-483-04 screws commonly used?

They are used across various industries, including automotive, for the assembly of engine parts, electronics, delicate component assembly, aerospace for their resistance to extreme conditions, and construction, where precise fastening is required.

How should 623-483-04 screws be installed?

It’s essential to use the correct Torx driver size for optimal performance. If necessary, ensure the installation area is pre-drilled to avoid material damage. The proper torque should be applied to prevent over-tightening and potential damage to both the screw and the substrate.

You May Also Read: Comprehensive Review of the Growneer Rotary Tool Kit: Your Versatile Companion for DIY Projects