Choosing the Right Shrink Wrapping Machine for Small and Large-Scale Operations

When it comes to packaging, organization and quality of their work, both time and again those companies will always come out tops. A shrink wrapping machine is one of the most valuable pieces of equipment for any company big and small that deals with packaging products. But it often remains a question: which kind of shrink wrapping machine is more suitable? Since there are different modes and kinds of outsourcing, it is imperative to choose the right mode to fit your operation and volume. To help you understand what to look for in shrink wrapping machines and how to find an ideal partner among packaging machine manufacturers, this article will present information on how to choose the right machine for small and large-scale enterprises.

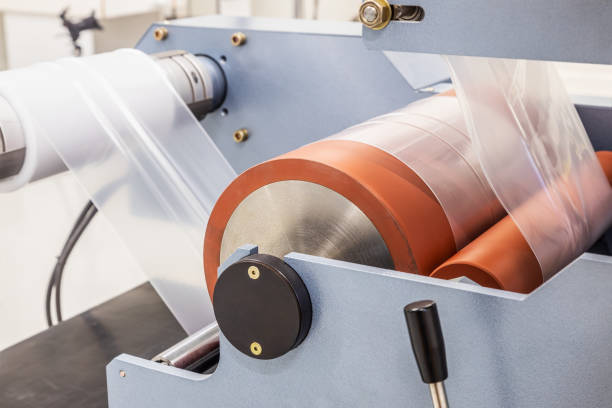

Shrink Wrapping Machine

A shrink wrapping machine is a process of wrapping a product in a plastic film with heat, then shrinking it around a product. The process of inserting a product in a plastic film and then having the plastic undergo shrinkage to match the shape of the product inserted. This package is usually used for foods, electronics items and products which are packed in large quantities. Shrink wrapping helps to protect the product during transportation, and also has a nice fastened look at the end. When it comes to shrink wrapping machines there are manual, semi and fully automatic machines, depending on the production preference. You will also realize that you have a particular requirement that you have to meet which will determine the right machine for your operation. The appropriate shrink wrapping machine shall not only upgrade packaging speed but also security of the relevant commodities to guarantee they get to the consumers in a perfect state. However, the versatility of the machine in handling products of different shapes and sizes also makes its applicability in many packaging situations.

Key Considerations When Choosing a Shrink Wrapping Machine

There are various things to look at while choosing a shrink wrapping machine, so that you can get the right equipment. Perhaps the first thing to consider is the number of products that need to be produced. If you are using the machinery for small-scale production, a manual or semi-automatic packaging machine could be enough, and you won’t need to spend a lot of money on it. However, if your business is of a wider scale and calls for the high speed packaging then the automatic shrink wrapping machine would be most ideal and appropriate for continuous runs. However, one should think about the size and form of the products to be packed, as well as the film kind that will be utilized. It helps a shrink wrapping machine manufacturer to advise a client on what machine to select depending on these factors. The right machine will help to increase flow and packaging targets, helping the business work more effectively. Concisely, compatibility with a specific type of film, and how easy it is to integrate the machine into your current process should also be met.

Benefits of Manual vs. Automatic Shrink Wrapping Machines

To the small firms or those firms recently established, a manual shrink wrapping machine is affordable. Often these machines involve the operator to fit the product into the film, and then the machine is run to shrink the wrapping. This option is more time-consuming and costs more than the fully automatic models In spite, this type may suit business organizations with shorter production capacity, and reasonable capital base. Conversely, an automatic shrink wrapping machine will be ideal for large scale operations that require the wrapping of hundreds or thousands of items in one hour. It means that most of these machines perform the functions on their own, saving labour expenses and enhancing output speed. Automatic machines, as their name suggests, are ideal for high production packaging solutions because they offer speed, precision and reduced operator interference, two aspects that are important for high production lines. By engaging packaging machine manufacturers will assist you in choosing the right packaging option for your line of packaging. In addition, the automatic machines are also more flexible in responding to a condition on packing film and packing shape thus becoming suitable for companies who need to pack a great number of products with different packaging.

Contemporary Space and Budget limitations

As mentioned earlier while selecting the shrink wrapping machine, both considerations with respect to space and cost should be kept in mind. Especially for those who are running smaller operations, space might be a constraint, therefore, it’s vital to choose a compact shrink wrapping machine. Most manual and semi-automatic models are compact and can be easily fitted into small areas hence suitable for establishments with small flooring space. Larger operations that need a high throughput capability, may call for a significantly heavier duty machine, that is, a fully automatic shrink wrapping machine from which however, less floor space is obtained. Also, think about operating cost, including maintenance and repairs and additional equipment should the shrink wrapping machine be integrated into your manufacturing process. When approaching packaging machine manufacturers, ensure you look at these long-term costs in order to be able to get the right solution within your range of affordance. These machines can usually be modified to match certain production volumes and therefore evaluating both your current and future requirements should guide you on the right choice to make.

Conclusion

Choosing the right shrink wrapping machine is a critical all important step, no matter if you own a startup company or you are handling a big company. How extensive and rigid your production line would be, the measuring of your production needs and space available as well as your financial requirement will assist you in choosing between a manual, semi-automatic or an automatic Shrink Wrapping Machine. Working together with packaging machine manufacturers guarantees you also have the best technology and support to satisfy your printing and packaging requirements. It therefore becomes evident that when an organization is selecting the right shrink wrapping equipment they should consider some factors that will enable them to get better results through improving costs, operations and the quality of the packaging. There is always that one machine that can make a huge difference in the running of the operations, enhancing presentation and minimizing the used materials. This means that getting the right machine for your packaging needs will put your business on the right footing for longevity in the running market.