Step-by-Step Guide to A.O. Smith 326PI34 Motor Replacement for Optimal Performance

Replacing the motor in your equipment can seem daunting, but with the proper guidance, it can become straightforward. The A.O. Smith 326PI34 motor replacement is necessary when your motor shows signs of wear or failure. This guide will take you through the step-by-step process, explain how to identify a compatible replacement and provide essential maintenance tips to keep your new motor running smoothly for years.

Signs That Your A.O. Smith 326PI34 Motor Needs Replacement

Before diving into the replacement process, it’s important to recognize when your motor requires attention. Common signs include:

- Overheating: A replacement is likely necessary if the motor frequently overheats despite troubleshooting.

- Unusual Noises: Grinding, humming, or rattling sounds indicate internal wear or damage.

- Frequent Breakdowns: A motor that fails repeatedly despite repairs may need to be replaced.

- Performance Decline: Inconsistent performance or inability to meet system demands can signal the end of the motor’s lifecycle.

- Visible Damage: Cracked housings, corroded components, or burnt wiring are clear signs that replacement is overdue.

Choosing the Right Replacement Motor

When selecting a replacement motor for the A.O. Smith 326PI34, ensure that the new motor meets these critical specifications:

- Horsepower (HP): Match the original motor’s horsepower for consistent performance.

- RPM: Ensure the revolutions per minute (RPM) align with the requirements of your equipment.

- Voltage: Verify that the voltage matches your system to avoid electrical issues.

- Frame Size: The A.O. Smith 326PI34 motor commonly uses a 48 or 56 frame. Double-check the frame size to ensure compatibility.

- Enclosure Type: Look for an Enclosed Non-Ventilated (TENV) motor to protect internal components from environmental factors.

Reliable suppliers like Century Motors (formerly A.O. Smith) provide compatible replacement motors that maintain the high-quality standards of the original.

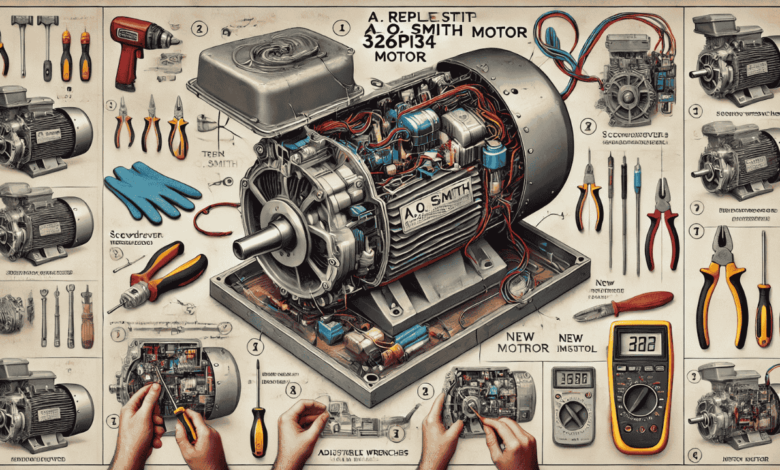

Tools and Materials Needed for Replacement

Before starting, gather the necessary tools and materials:

- Screwdrivers (flathead and Phillips)

- Adjustable wrench or socket set

- Multimeter for testing electrical connections

- Voltage tester

- Personal protective equipment (gloves and safety glasses)

- Lubricant (if required for bearings)

Step-by-Step Guide to Replacing the A.O. Smith 326PI34 Motor

Follow these steps to replace your motor safely and effectively:

Disconnect Power

Safety comes first. To disconnect the power supply, turn off the circuit breaker or unplug the equipment. Then, use a voltage tester to ensure no current is flowing.

Access the Motor

Open the motor housing by removing screws or bolts. This will give you access to the motor and its mounting components.

Disconnect the Wiring

Carefully disconnect the motor’s electrical connections. Label or take photos of the connections to ensure accurate reinstallation.

Remove the Old Motor

Loosen and remove the motor from its mounting bracket. Keep the screws, bolts, and any additional hardware for reuse.

Prepare the New Motor

Inspect the replacement motor to ensure it matches the original specifications. Apply lubricant to the bearings if required.

Install the New Motor

Align the new motor with the mounting points and secure it using the screws or bolts. Ensure the motor is positioned correctly to avoid alignment issues.

Reconnect the Wiring

Follow the wiring diagram or your labeled connections to reconnect the electrical wires. Double-check all connections for security.

Test the Motor

Restore power to the equipment and test the motor for proper operation. Listen for unusual noises and verify smooth performance.

Reassemble the Housing

Once the motor passes the test, reassemble the housing and ensure all components are securely in place.

Common Issues to Watch For During Replacement

While replacing the motor, keep an eye out for potential issues such as:

- Incorrect Wiring: Mismatched connections can lead to malfunction or damage.

- Faulty Capacitor: If the motor fails to start after replacement, the capacitor may need to be replaced.

- Alignment Problems: Ensure the motor is aligned with the pump or system to prevent unnecessary wear.

- Seal Leaks: Check for leaks around the motor’s shaft seal to avoid water damage.

Maintenance Tips for Your New Motor

To extend the lifespan of your new A.O. Smith 326PI34 motor, follow these maintenance tips:

- Regular Cleaning: Dust and debris can clog ventilation and cause overheating. Clean the motor housing periodically.

- Lubrication: Apply the appropriate motor oil to bearings at recommended intervals to reduce friction.

- Inspect Wiring: Check for frayed wires or loose connections regularly.

- Monitor Performance: Pay attention to changes in performance, noise levels, and efficiency.

Benefits of Replacing Your A.O. Smith 326PI34 Motor

Upgrading to a new motor offers several advantages:

- Improved Efficiency: A new motor ensures optimal energy consumption and performance.

- Reduced Downtime: Replacing a failing motor minimizes interruptions to your operations.

- Enhanced Durability: Modern motors often have improved components and designs for longer service life.

- Lower Maintenance Costs: A properly installed and maintained motor reduces the need for frequent repairs.

Where to Buy a Replacement Motor

You can purchase a replacement motor from authorized distributors, online marketplaces, or local repair shops. Reputable suppliers include:

- Grainger: Offers a wide range of industrial motors.

- Boat Lift Warehouse: Specializes in lift motors and pre-wired options.

- Pump Distributors: Many carry Century-compatible motors for easy replacement.

Conclusion

Replacing the A.O. Smith 326PI34 motor doesn’t have to be a complex task. Following this guide and using the right tools and techniques can ensure a successful replacement that restores your equipment’s performance and reliability. Remember to prioritize safety, choose a compatible replacement motor, and perform regular maintenance to maximize the lifespan of your new motor. With proper care, your equipment will continue running efficiently for years.

You May Also Read: Oster Tower Fan Servicing Centeres in Hyderabad or Secunderabad