What Keeps Hospitals Running: A Closer Look at Modern Medical Equipment

Behind every successful surgery, routine diagnostic test, or critical care procedure lies an ecosystem of reliable, expertly engineered medical equipment. These devices both big and small, obvious and concealed, are the backbone of any medical institution. Among them, endoscope parts represent a microcosm of complexity and precision. These are some of the parts that are not usually visible to the patients but are important in diagnosis and treatment in many specializations.

This article explores the scope of medical equipment, the significance of endoscopic technology, and the role of thoughtful design and maintenance in sustaining healthcare’s most essential tools.

What Counts as Medical Equipment?

The term medical equipment encompasses a wide range of devices used in the prevention, diagnosis, monitoring, and treatment of diseases and conditions. These tools are highly diverse in terms of complexity, size and functionality and their availability is essential in almost every department within a hospital environment.

Medical equipment is generally categorized into four types:

- Diagnostic equipment: Devices like ultrasound machines, MRI scanners, and endoscopy units that help identify health conditions.

- Therapeutic equipment: Tools such as infusion pumps, ventilators, and surgical lasers used during treatment.

- Life-support equipment: Critical devices like heart-lung machines and defibrillators that help maintain or restore vital functions.

- Medical laboratory equipment: Instruments used for analyzing biological samples, including blood analyzers and centrifuges.

Every endoscope equipment has a particular purpose and usually combines a broad range of smaller modules. We find this in the tubing of a dialysis machine or the fiber optics of an endoscope, and these small components need to operate perfectly with one another to deliver the correct and safe treatment of patients.

The design and performance standards for medical equipment are governed by strict international regulations. The devices are not only required to work accurately but also to meet hygienic requirements, durability, and safety to the user. As an example, the invasive procedures equipment should be sterilizable, corrosion-resistant, and biocompatible. This is especially relevant when considering endoscope parts, which are regularly exposed to bodily fluids and sterilization chemicals.

Endoscope Parts: Small Components, Big Responsibilities

Endoscopy is a low impact diagnostic and surgical method which is based on thin, flexible devices with strong imaging and control functions. Central to this innovation is the assembly of highly specialized endoscope parts.

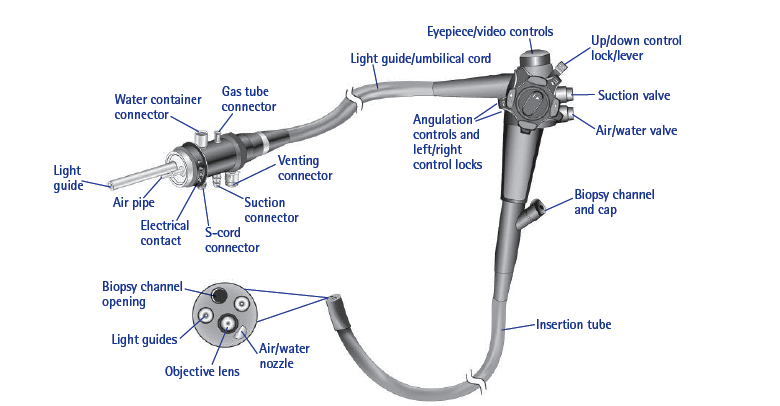

An endoscope is not just a camera on a tube. It consists of a system comprising of:

- Insertion tube: The main shaft that enters the body, housing all internal channels and wiring.

- Light guide bundle: A fiber-optic system that transmits light from an external source into the body cavity.

- Biopsy or suction channels: Narrow tubes that allow the introduction of instruments or removal of fluids.

- Distal tip: The business end of the scope containing the lens, LEDs, and control wires.

- Control body: The external portion handled by the clinician, containing valves, knobs, and connection ports.

- Bending section: A highly flexible part that allows controlled angulation of the distal tip during navigation.

Each of these endoscope parts must be engineered with extreme precision. To illustrate, the light guide bundle should provide consistent illumination and should not cause heats damage, and the bending segment should bend and not cause damages to internal channels. They are not interchangeable parts–they are very specific to the model, diameter and intended use of the endoscope.

Moreover, many endoscope parts must balance miniaturization and mechanical strength. They have to be small so that they can fit in the smallest openings in the body but strong enough to flex and bend and be subjected to pressure and sterilization repeatedly.

Durability is even more important in surgical endoscopy. Surgeons use the endoscope in real-time visuals in order to make incisions or to remove tissue. Fogged lens, blocked biopsy channel, an inappropriately angulated tip, or any failure are prone to complications or time-consuming procedures and false diagnoses.

Thus, maintaining high-quality endoscope parts is a clinical imperative, not merely a technical preference.

Maintenance and Replacement: Keeping Equipment Safe and Accurate

Medical equipment—especially reusable devices like endoscopes—requires regular maintenance to ensure they meet hygiene standards and functional accuracy. Although there are certain problems, which can be related to usage patterns, most of them can be prevented by providing timely care and changing parts.

In the case of endoscopes, important maintenance procedures are:

- Leak testing to identify the damage of internal channels

- Manual cleaning and automated cleaning to eliminate biological residue

- Between patients high-level disinfection or sterilization

- Inspection and replacement of worn endoscope parts, such as valves, insertion tubes, and light connectors

With time, parts such as the bending section, O-rings or seals can wear out as a result of heat and chemicals. This deterioration may deteriorate performance and patient safety. Many manufacturers offer OEM replacement endoscope parts to maintain equipment integrity without requiring full unit replacement.

Similar attention is needed for broader medical equipment. Standard hospital protocols include calibration of diagnostic instruments and software updates, and part replacement. Cumulative effects of patient outcomes can be caused by the slightest inaccuracies in imaging or measurement equipment without regular checks.

Proactive maintenance schedules are important in facilities that undertake large volumes of procedures. Hospitals often rely on biomedical engineers or third-party service providers to inspect and repair devices using certified medical equipment standards.

Good quality spare parts, frequent audits, and written cleaning procedures can greatly prolong the life of costly equipment and maintain patient confidence.

Conclusion:

From hospital wards to operating rooms, the effectiveness of modern medicine hinges on the performance and precision of medical equipment. Within this broad category, the role of highly specialized endoscope parts cannot be overstated. These miniature, complex parts are the key facilitators of minimally invasive diagnostics, early disease diagnosis, and patient safety.

Their functionality, configuration, and connection to the wider equipment systems are examples of the complexity of the current healthcare technologies. To appreciate the workings of hospitals, diagnosing processes of doctors, and excellence in engineering that assists in saving lives, it is important to comprehend the depth of the tools being used.