How Pyrolysis and Crushing Machines Are Driving Circular Plastic Economies?

The problem of plastic pollution is growing, which puts strains on the landfills, ecosystems, and urban infrastructure. Although recycling has been in existence since decades, the traditional systems are unable to sort through huge quantities of mixed and contaminated plastics. To this end, the world is moving towards abandoning linear take-make-dispose models and moving towards circular economies, where wastes are transformed into valuable resources.

At the center of this transformation are two powerful technologies: the plastic crusher machine and the pyrolysis machine. They work together and degrade waste and turn it into fuel or reuse materials. In this article, we will discuss how these machines can help to manage plastic sustainably, at a larger scale, efficiently and environmentally friendly.

Plastic Waste Processing: The Need for Scalable and Efficient Solutions

Conventional methods of recycling plastic like mechanical melting or downcycling fail to meet the mark because of the complication involved in sorting and profitability. A large number of plastics cannot be recycled even with simple infrastructure, and they are therefore discarded to the incinerators or disposed of in the environment.

The technologies that are required are those that can process a large variety of plastics, are contamination-tolerant, and can produce high-value products. Enter the plastic crusher machine and pyrolysis machine—technologies that together offer scalable, efficient solutions for processing plastic waste.

They allow decentralized recycling centers, lower logistics expenses, and increase the recycling rates to a considerable extent. They recycle plastic to recapture materials and energy content of wasted plastic, thus opening the door to circular plastic economies.

What is a Plastic Crusher Machine and Why It’s Essential in Pre-Treatment?

A plastic crusher machine is an important equipment used to reduce plastic waste into smaller, uniform particles. This pre-treatment procedure is crucial to recycling procedures – be it mechanical reuse, chemical disintegration, or fuel transformation.

Crushing enhances surface area and eliminates air pockets in the plastic, hence easy to handle, store and process. More importantly, it ensures that plastic waste can be efficiently and uniformly fed into downstream equipment, such as extruders, pelletizers, or pyrolysis machines.

It also assists in the identification of contaminants, better separation of various materials and improves the whole throughput. In short, the plastic crusher machine serves as the foundational step that determines the success and efficiency of the entire recycling loop. It turns chaotic plastic waste into even material that can be processed.

Working Mechanism and Applications of a Plastic Crusher Machine:

The plastic crusher machine operates through a system of rotating and stationary blades enclosed in a chamber. Once plastic waste is inserted into the machine, it is cut down to tiny pieces by fast rotating cutters. The pieces normally measure between 10-30 mm.

Most models have a screen mesh which filters crushed material so that uniform output is guaranteed. Bigger particles are re-crushed, which increases consistency. Heavy duty crushers can also be equipped with water-cooling systems, soundproofing panels and overloading protection.

There are broad applications. PET bottles, caps and shrink wraps are processed by crushers in the packaging industries. They cut dashboards, trims, and bumpers in automotive recycling. Household or restaurant post-consumer waste such as plastic bags, containers and wrappers is also crushed.

Most importantly, in chemical recycling, crushed plastic is the preferred feedstock for pyrolysis machines. Even heating and increasing energy efficiency is guaranteed by uniform particle size. In all uses, crushing is crucial in ensuring that plastic waste is manageable and is ready to be transformed.

Transforming Crushed Waste: How a Pyrolysis Machine Converts Plastic into Energy

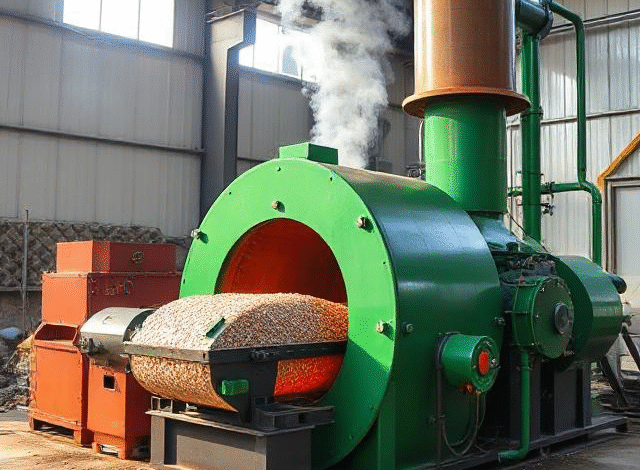

Once plastic is crushed into uniform granules, it’s ready for thermal conversion through a pyrolysis machine. Pyrolysis is a chemical reaction, which involves the decomposition of plastic polymers into smaller molecules through heating without oxygen.

The plastic is decomposed in the reactor at temperatures of 350-500 o C, producing a mixture of pyrolysis oil, syngas (synthetic gas) and solid char. The oil can be refined to diesel or be utilized as an industrial fuel. The syngas is recapturable and can be used to fuel the system and the char has uses in both construction and in carbon based products.

The input is crucial to the efficiency and the quality of the product of pyrolysis. Crushed, dry, and uniform material—prepared using a plastic crusher machine—ensures better thermal contact, controlled reaction times, and minimized residue.

This closed loop conversion process turns plastic waste into energy, providing a substantial environmental victory and providing commercial payback to both the recycling processes and municipalities.

Advantages of Using a Pyrolysis Machine in Waste-to-Fuel Technologies:

The pyrolysis machine offers several advantages over conventional recycling systems, especially when processing mixed or contaminated plastic waste. In comparison to mechanical recycling, it does not involve tight sorting by polymer type or color.

Pyrolysis processes low-grade plastics such as LDPE, HDPE and PP which are usually discarded in conventional plants. It converts them into energy products of great demand like pyro-oil and gas. The fuels minimize the dependence on fossil materials and generate additional income to waste processors.

The other major benefit is low emissions. Pyrolysis systems of modern design also have gas scrubbing units and sealed reactors and so the impact on the environment is minimal. They can also be scaled easily, through their modular design, one can start with a small plant that serves the local community but gradually expand it to be able to process tons of waste in a day.

When combined with pre-treatment equipment like a plastic crusher machine, pyrolysis becomes even more efficient, forming a circular solution that minimizes landfill dependency, reduces carbon emissions, and turns plastic waste into valuable fuel resources.

Conclusion:

Good intentions are not enough to forge the road to a circular plastic economy; smart technology and efficient integration is needed. The combination of plastic crusher machines and pyrolysis machines represents a breakthrough in modern recycling. Whether decreasing the amount of plastic waste or reclaiming fuel and having a minimal impact on the environment, these machines present a closed-loop system that is environmentally friendly and commercially feasible.

Since countries and industries seek to overcome plastic pollution and achieve sustainability goals, this dynamic duo serves as a model of transformation. Not recycling, it is turning waste into opportunity, bottle by bottle, cycle by cycle in the pyrolysis plant.