A Complete Guide to Laser Marking and Engraving Machines

From intricate jewelry designs to durable product labeling, laser marking and engraving machines have become an essential tool in both creative and industrial settings. This technology delivers unmatched precision, speed, and versatility enabling users to transform ordinary materials into works of art or functional components.

Whether you’re a small business owner, a hobbyist, or a large-scale manufacturer, understanding how these machines work and what features matter most will help you choose the right one.

What Is a Laser Marking and Engraving Machine?

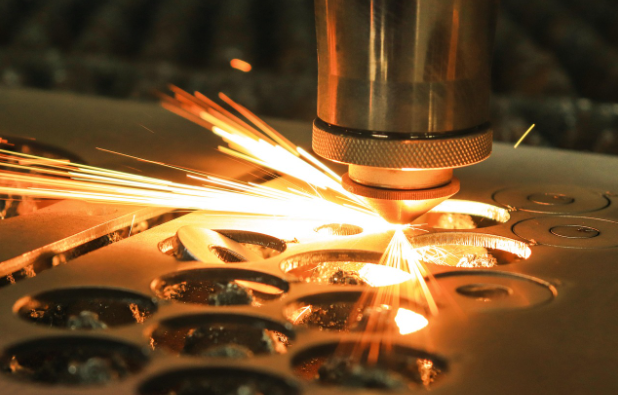

A laser marking and engraving machine uses concentrated beams of light to etch, engrave, or mark the surface of materials.

- Laser marking changes the appearance or chemical composition of the material without removing material, good for adding serial number, bar code, or logo.

- Laser engraving removes layers from the material, creating deeper, more noticeable impressions perfect for decorative designs or functional text.

This dual capability makes the machines popular in industries such as electronics, automotive, signage, and personalized gifts.

Types of Laser Machines and Their Uses

1. Fiber Laser Machines

- Best for metals, plastics, and hard materials.

- Commonly used in industrial applications for permanent marking.

2. CO₂ Laser Machines

- Ideal for wood, leather, acrylic, glass, and paper.

- Great for creative and craft industries.

3. Diode Laser Machines

- Compact, affordable, and versatile.

- Suitable for light-duty engraving tasks.

Key Features to Consider Before Buying

When choosing a laser marking and engraving machine, consider:

- Power Output (Wattage): Higher power means faster and deeper engraving.

- Work Area Size: Larger areas allow for bigger projects.

- Precision and Speed: Look for high DPI and adjustable speed settings.

- Cooling System: Prevents overheating during continuous use.

- Safety Features: Such as enclosures, emergency stops, and air filtration.

Materials You Can Work With

A well-designed laser marking and engraving machine can work on:

- Wood

- Acrylic

- Glass

- Leather

- Metals (stainless steel, aluminum, gold, etc.)

- Stone

- Fabric

This flexibility makes it appealing to both artists and engineers.

Introducing the Creality Falcon Laser Series

One brand making waves in the laser engraving market is Creality Falcon. Known for blending cutting-edge technology with user-friendly design, their machines cater to a wide range of users.

Falcon CR

A budget-friendly choice for beginners, offering consistent performance and straightforward controls.

Falcon A1

Features smart automation, safety enclosure, and camera-assisted precision: perfect for those who want high-quality results with minimal setup.

Falcon2 Series (22W & 40W)

Offers powerful performance for faster cutting and engraving, with integrated air assist to produce cleaner edges.

Falcon2 Pro 60W

Designed for professionals and industrial users, capable of cutting thicker materials in one pass while maintaining pinpoint accuracy.

Creality’s lineup ensures there’s a solution for every level, from hobbyists to large-scale production.

Benefits of Using a Laser Marking and Engraving Machine

- High Precision: Achieve intricate details impossible with manual tools.

- Non-Contact Process: No physical wear on the machine or the material.

- Versatility: Works with a wide range of materials.

- Cost-Effective: Reduces waste and production time.

- Repeatability: Perfect for mass production with consistent results.

Maintenance and Safety Tips

To get the best performance from your machine:

- Clean the lens and mirrors regularly.

- Keep the work area dust-free.

- Use the recommended cooling method.

- Wear protective eyewear when operating open-frame systems.

- Follow manufacturer guidelines for materials and settings.

Future Trends in Laser Engraving Technology

Laser machines are becoming:

- More powerful yet compact: Allowing small workshops to achieve industrial-level results.

- AI-integrated: For automated design optimization.

- Eco-friendly: With reduced power consumption and safer exhaust systems.

Conclusion

A laser marking and engraving machine opens up a world of possibilities for customization, branding, and manufacturing. Whether you’re personalizing a gift or producing intricate industrial components, the right machine can elevate your results.

Brands like Creality Falcon, with their Falcon CR, Falcon A1, Falcon2, and Falcon2 Pro, offer options that balance innovation, quality, and user-friendliness making them a worthy consideration for your next investment.

FAQs

1. What is the difference between laser marking and laser engraving?

Laser marking changes the surface color or texture without removing material, while laser engraving removes layers from the material to create a deeper, permanent design.

2. Can one machine do both marking and engraving?

Yes, many modern machines, including models in the Creality Falcon series, can handle both marking and engraving depending on the settings and material.

3. What materials can I use with a laser marking and engraving machine?

You can work with wood, acrylic, leather, glass, stone, fabrics, and metals like stainless steel or aluminum — depending on the machine type and power.

4. Do I need special training to operate a laser engraver?

Not necessarily. Many machines are beginner-friendly, especially models like the Falcon CR or Falcon A1, which have intuitive controls. However, reading the manual and following safety guidelines is essential.

5. How long do laser engraving machines last?

With proper maintenance such as cleaning lenses, using the correct cooling, and operating within recommended settings a quality laser engraver can last for many years.