How Can Precision CNC Milling Strengthen Your Global Supply Chain in 2025?

Introduction

In the global supply chain, manufacturers in 2025 face a triple threat: geopolitical tensions, increased logistics volatility, and rising demand uncertainty. Traditional manufacturing models, such as reliance on fixed molds, long production cycles, and high defect rates, have become vulnerable links in the supply chain. These methods lack digital integration, production flexibility, and precision, leading to slow market response, high inventory costs, and potential disruptions to the entire production process due to delays in a single critical component.

This article will demonstrate that precision CNC milling technology – especially its advanced forms deeply integrated with digitalization and automation – is not merely a tool for parts processing, but a strategic asset for building agile and reliable supply chains. By analyzing its working principles, specific applications in key industries, and a strategic value assessment framework, we will reveal how CNC milling service is evolving from a production workshop tool to a core pillar of the supply chain.

So, how exactly does precision CNC milling empower global supply chains, making them more resilient in 2025?

Why Supply Chain Resilience is a Top Priority for Manufacturers in 2025?

Amid escalating disruptions, building resilient operations has transitioned from optional to imperative. Manufacturers must now prioritize agility, predictability, and quality consistency to navigate volatile markets and sustain competitive advantage.

1. Profound Changes in the Global Supply Chain Environment

Industry analysis shows that over 70% of manufacturing companies have experienced supply chain disruptions in the past three years, resulting in an average production capacity loss of 15%-20%. Geopolitical factors are driving the rise of “nearshoring” and “friend-shoring” models, with companies increasingly prioritizing shorter physical distances to reduce risk. At the same time, the fragmentation of market demand has accelerated the adoption of small-batch, multi-variety production models, placing higher demands on the agility and predictability of the manufacturing process.

2. Bottlenecks and Risks of Traditional Manufacturing Models

In a volatile environment, the limitations of traditional manufacturing models become apparent. Reliance on molds leads to high initial investment and long iteration cycles, making it difficult to respond quickly to design changes or unexpected demands. The low level of digitalization in the production process makes the process opaque, and quality problems are often only discovered later, leading to mass rework or even scrapping. These factors collectively weaken the supply chain’s adaptability, exposing companies to the risk of cost overruns and delivery defaults.

3. Core Objectives of a Resilient Supply Chain

Building a resilient supply chain requires focusing on three main objectives:

- Agility: the ability to quickly adjust production plans and product designs.

- Predictability: Achieving transparent management throughout the entire process through digital tools.

- Quality Consistency: Ensuring every component meets strict standards, eliminating assembly risks from the source. Precision CNC milling technology, with its digital foundation and precise control capabilities, is the key path to achieving these goals.

How does CNC milling become the cornerstone of modern manufacturing?

CNC milling’s digital-driven nature enables precision, repeatability, and material flexibility, making it indispensable for agile production. By eliminating tooling dependencies and supporting rapid iterations, it bridges design innovation and scalable manufacturing.

1. The Core Principle of Digital Driving

What is CNC Milling? The essence of CNC (Computer Numerical Control) milling is subtractive manufacturing: using pre-programmed digital instructions (G-code) to drive the machine tool, precisely cutting solid material blanks into the target shape. Its core advantage stems from digitalization: once the CAD model is converted into a CAM program and verified through simulation, it can be reproduced infinitely, ensuring high dimensional consistency across millions of parts. This “digital twin” model eliminates human error in traditional processing, laying the foundation for high-quality mass production.

2. The Dual Advantages of Repeatability and Design Freedom

Unlike processes constrained by molds (such as injection molding), CNC milling does not require expensive dedicated tooling. Design changes only require adjusting the program, greatly reducing trial-and-error costs and iteration cycles. This allows engineers tofreely explore better structural designs (such as topology optimization), conduct material experiments, or quickly respond to urgent orders. This flexibility is precisely what dynamic supply chains need.

3. Wide Material Adaptability

From aerospace-grade aluminum alloys and titanium alloys to medical-grade PEEK engineering plastics, CNC milling supports the precision machining of hundreds of materials. This broad compatibility allows companies to flexibly select materials based on actual supply conditions, cost budgets, or performance requirements, reducing reliance on specific material suppliers and enhancing supply chain robustness.

How do advanced CNC capabilities (such as 5-axis machining) directly reduce supply chain risks?

Multi-axis technology enhances accuracy, slashes lead times, and supports complex geometries in single setups. These capabilities mitigate delays, improve interchangeability, and empower cost-efficient small-batch production—key pillars of supply chain resilience.

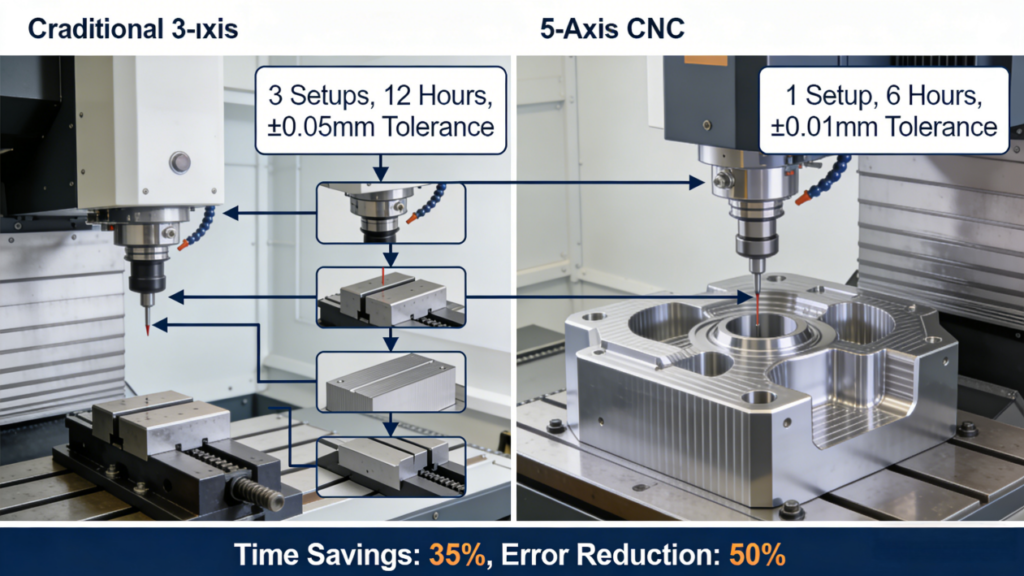

1. Complete Machining of Complex Parts in a Single Setup

5-axis CNC technology adds two rotational axes (such as A/C axes) to the traditional three-axis linear motion. This allows the tool to approach the workpiece from any direction, completing the machining of complex surfaces, deep cavities, and angled holes in a single setup. For example, components with aerodynamic surfaces, such as drone wings, require multiple re-clamping and step-by-step processing on a 3-axis machine, while 5-axis technology can complete the process continuously, avoiding cumulative errors caused by datum shifts.

2. Improved Accuracy and Interchangeability, Eliminating Assembly Line Downtime

According to the ASME Y14.5-2018 geometric dimensioning and tolerancing standard, part interchangeability depends on strict control of geometric tolerances. 5-axis machining ensures the relative positional accuracy between all features by maintaining a single machining datum. This means that parts produced in multiple factories worldwide can beassembled seamlessly, avoiding production line downtime due to dimensional deviations and ensuring the smooth operation of globalized production.

3. Increased Efficiency and Cost Optimization

Reducing the number of clamping operations directly leads to time savings: the processing cycle for complex parts can be shortened by an average of more than 30%. At the same time, it reduces the need for specialized fixtures and the frequency of operator intervention, reducing tooling and labor costs. This efficiency gain is particularly significant for small-batch production, making “on-demand production and rapid delivery” possible.

What Role Does CNC Technology Play in Sustainable and Digitally Connected Manufacturing?

CNC integrates sustainability through optimized material usage and energy recovery, while digital threads enable real-time monitoring and distributed production networks. This synergy fosters eco-efficiency and operational transparency across global supply chains.

1. Sustainable Manufacturing Practices

Precision CNC milling maximizes material utilization through optimized tool paths (such as high-speed cutting strategies), significantly reducing waste. Modern CNC machines integrate energy recovery systems, reducing energy consumption per unit of output. More importantly, high-precision machining significantly reduces part scrap and rework due to dimensional deviations, practicing sustainable manufacturing at the process level.

2. Digital Thread and Real-time Monitoring

CNC is a natural entry point for smart manufacturing. FromCAD models to CAM programming, and then to the machine’s CNC system, a complete digital thread is formed. Integrated sensors can monitor spindle load, tool wear, and vibration data in real time, enabling predictive maintenance and avoiding unplanned downtime. Thisdata-driven transparency allows managers to accuratelypredict delivery dates and enhance supply chain predictability, which aligns perfectly with the smart manufacturing framework advocated by National Institute of Standards and Technology (NIST).

3. Building a Resilient Production Network

A network of CNC machine tools interconnected through a central Manufacturing Execution System (MES) can form a distributed manufacturing network. When one site experiences a production disruption, production tasks can be quickly switched to other sites, with programs and data synchronized through the cloud, ensuring consistent output quality. This capability provides a strategic buffer against regional disruptions.

Can real-world examples demonstrate the impact of CNC milling on aerospace and automotive supply chains?

- Aerospace: Rapid Response to Engine Component Needs: During routine maintenance, an airline discovered that a turbine blade in one of its engines needed urgent replacement. Traditional casting methods would require new molds, taking up to 12 weeks. A supplier with 5-axis CNC machining capabilities completed the precision milling of a titanium alloy blade in 3 days based on a digital model, delivering a replacement part that fully met the standards, avoiding significant losses due to prolonged aircraft downtime.

- Automotive Electrification: Accelerating Battery Tray Iteration: An electric vehicle manufacturer needed to improve the lightweight design of its battery tray to increase driving range. Using CNC milling, the design team completed the entire process from design to functional prototype manufacturing in two weeks and used multiple CNC machines to produce small batches of prototypes in parallel, supporting the customer’s strategic goal of launching 6 months ahead of competitors. Manufacturers with relevant industry certifications (such as IATF 16949) demonstrate a critical role in such high-value projects.

How should companies evaluate high-volume precision machining partners?

Selecting the right partner demands scrutiny of technical capabilities, quality certifications, and digital integration maturity. A rigorous evaluation ensures alignment with resilience goals and long-term supply chain success.

1. Technical Capabilities and Equipment Level

Evaluation points include: the number of axes of the machine tools, precision indicators, and whether advanced models such as turn-mill machines are available. The partner should be able to provide a processing parameter library and process experience for your specific materials, demonstrating their technical depth.

2. Quality Certification System and Traceability

Mandatory standards should include ISO 9001 quality management system certification. For specific industries, such as aerospace, AS9100D is required, and for medical devices, ISO 13485 is required. These certifications ensure full control and traceability from raw material warehousing to finished product delivery, providing institutional assurance of consistent quality.

3. Digital Integration and Project Management Capabilities

Excellent partners should be able to seamlessly integrate into your digital processes, support standard format (such as STEP) model integration, and provide a transparent project progress tracking system. Smooth communication mechanisms and agile project management capabilities are just as important as technical capabilities, and are key soft skills for ensuring on-time delivery.

Conclusion

In the uncertain landscape of 2025, investing in precise, digital, and flexible CNC milling technology has shifted from an “option” to a “strategic necessity” for building a robust supply chain. It directly reduces supply chain vulnerability by significantly shortening time to market, ensuring ultimate quality consistency, and providing unparalleled design flexibility.

FAQs

Q1: What are the main differences between CNC milling and 3D printing for functional prototyping?

A: CNC milling is a subtractive process, cutting parts from a solid billet, resulting in parts with excellent mechanical properties and surface finish consistent with the final product, making it ideal for testing form, fit, and function. 3D printing is an additive process, which facilitates the manufacturing of highly complex geometries, but its parts often exhibit anisotropy and rougher surfaces.

Q2: How tight of tolerances can precision CNC milling typically maintain?

A: Precision CNC milling can consistently maintain tolerances of ±0.025 mm (±0.001 inches) or even tighter, depending on part size, material, feature complexity, and machine capabilities. It is recommended to use standards such as GD&T to specify tolerances based on actual functional requirements to avoid unnecessary costs.

Q3: Is CNC milling cost-effective for small-batch production?

A: Yes, for small to medium-volume production (tens to thousands of pieces), CNC milling is highly cost-effective. It eliminates the high upfront costs and long lead times associated with molds required for injection molding or casting, making it ideal for transitional production, custom parts, and situations where design changes are likely, providing unparalleled flexibility.

Q4: What are the most commonly used materials for CNC milling in industrial applications?

A: A wide range of materials are suitable. Metals such as aluminum alloys (lightweight, easy to machine), stainless steel (high strength, corrosion resistant), and titanium alloys (high strength-to-weight ratio) are very common. Engineering plastics such as PEEK (high temperature resistance) and polyoxymethylene (low friction) are also frequently used.

Q5: How does 5-axis CNC milling shorten lead times compared to 3-axis milling?

A: 5-axis machining allows the tool to approach the workpiece from almost any direction in a single setup, eliminating the need for multiple manual repositioning steps required in 3-axis machining. This single-setup capability significantly reduces overall machining time, minimizes errors associated with repositioning, and allows for the machining of more complex geometries in one go.

Author Bio

The insights in this article are provided by the team of precision manufacturing experts at LS Manufacturing. The company is a leading provider of custom parts manufacturing services, specializing in helping global clientssolve complex supply chain challenges. The team adheres to rigorous industry standards and is committed to creating value for clients through advanced manufacturing technologies.Businesses can learn more about the company’s CNC milling services by visiting their official website and immediately receive a design for manufacturability analysis tailored to their specific project, exploring how to optimize their production processes.