How to Slash Product Development Costs: A Strategic Guide to Rapid Prototyping

Introduction

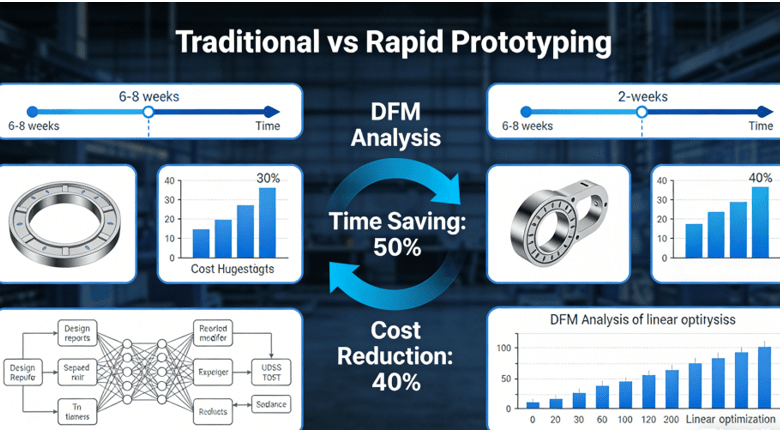

In today’s highly competitive market, companies face immense pressure to bring innovative products to market faster. However, traditional product development processes often encounter bottlenecks due to long prototyping cycles, cost overruns, and repeated design revisions, leading to missed critical market opportunities. The root of the problem often lies in the disconnect between design and manufacturing. Many teams begin prototyping without conducting design for manufacturability (DFM) analysis, resulting in potential design flaws only being discovered during the expensive production phase, leading to significant waste of time and resources.

This article will explore how strategically applying rapid prototyping services, particularly those integrated with upfront DFM analysis, can transform prototyping from a passive “physical verification” tool into an active “risk control and optimization” tool.

What Are the Key Prototyping Technologies and When Should You Use Them?

In the field of rapid prototyping, choosing the right technology is crucial, as it directly impacts the functionality, cost, and time of the prototype. This section will go beyond a simple list of technologies, delving into the core advantages and applicable scenarios of mainstream technologies to help you make decisions based on your specific needs.

1. CNC Machining: The Preferred Choice for High-Precision and High-Strength Functional Testing

CNC machining, through subtractive manufacturing, cuts parts from solid blanks, making it ideal for functional testing prototypes requiring high strength and precision. For example, for drone components or medical device prototypes, CNC ensures consistent material properties and strict dimensional tolerances. As emphasized by the ASME Y14.5 standard, clear geometric dimensions and tolerances are fundamental to ensuring interchangeability for functional prototypes involving assembly. Compared to 3D printing, CNC offers advantages in metal prototyping, but the cost and time may be higher.

2. 3D Printing: A Powerful Tool for Complex Geometries and Rapid Verification

3D printing technologies, such as SLA, SLS, and FDM, achieve rapid prototyping by layering materials, making them particularly suitable for prototypes with complex geometries. SLA is suitable for high-detail appearance models, SLS for functional nylon parts, and FDM for low-cost concept verification. Its biggest advantage lies in speed: for complex structures, 3D printing can be completed in a few days, while CNC machining may require longer setup times. However, the strength of 3D printed parts may be inferior to CNC machined parts, making them suitable for non-load-bearing applications.

3. Vacuum Casting: The Ideal Choice for Small-Batch Appearance Part Prototyping

When a small batch (e.g., 50-100 pieces) of prototypes is needed for market testing or appearance review, vacuum casting is a cost-effective option. It replicates parts using silicone molds, offers a wide range of material choices, and provides high surface quality. However, mold making requires extra time, so it is more suitable for larger prototype batches. When choosing, the technical characteristics should be weighed based on the purpose of the prototype (e.g., structural verification, appearance review, or market testing).

Why is DFM Analysis the Most Critical Step in Prototyping?

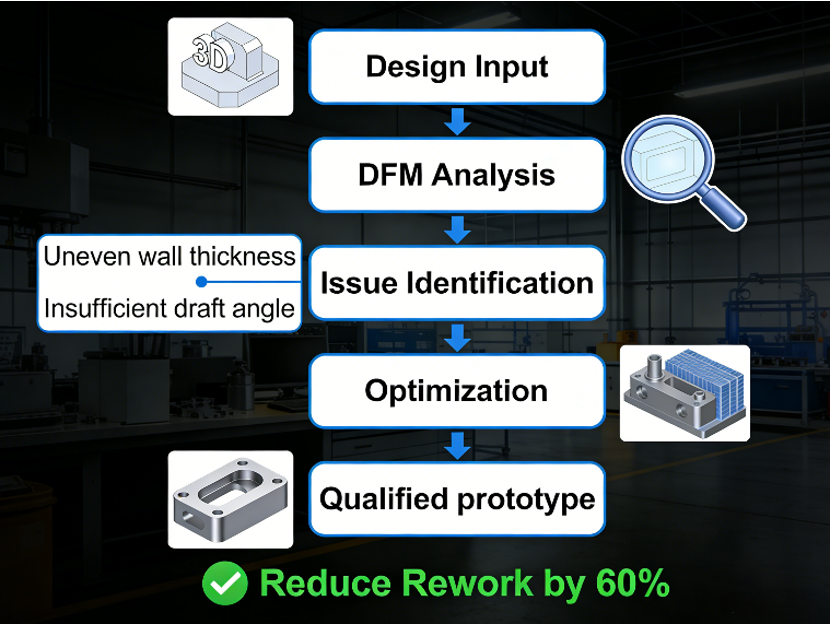

DFM analysis is a core part of the rapid prototyping process, fundamentally saving costs and time by identifying design problems before manufacturing. Neglecting this step can lead to prototype failure and project delays.

1. Optimizing Wall Thickness and Avoiding Deformation

Many designs experience deformation or cracking during the prototyping stage, often due to uneven or excessively thin wall thickness. DFM analysis simulates the manufacturing process and recommends reasonable wall thickness designs to avoid stress concentration. For example, for plastic parts, DFM can recommend a uniform wall thickness distribution to ensure balanced flow during injection molding and reduce the risk of deformation.

2. Rationalizing Tolerances to Control Costs

Overly strict tolerances significantly increase processing time and costs. DFM analysis helps teams differentiate between critical functional dimensions and non-critical areas, rationalizing tolerances to control expenses while ensuring performance. Choosing a supplier that provides in-depth, professional rapid prototyping services ensures that risks are mitigated from the outset.

3. Draft Angles and Design for Manufacturability

For injection molding or vacuum casting prototypes, DFM checks the draft angles to ensure that parts can be easily removed from the mold. Lack of draft angles can lead to mold damage or part defects. Through early analysis, DFM eliminates design flaws at the initial stage, achieving “doing it right the first time” and saving the cost of repeated modifications.

Figure 2: DFM analysis identifies design flaws like uneven wall thickness early in the prototyping process, enabling corrections before manufacturing and cutting rework rates significantly.

How to Evaluate a Prototyping Partner Beyond Price?

When choosing a prototyping partner, price should not be the only consideration. A true partner provides engineering support to ensure project success. The following is a multi-dimensional evaluation framework.

1. Engineering Support Capabilities and DFM Proactiveness

Excellent suppliers proactively provide DFM (Design for Manufacturability) analysis, rather than passively executing orders. This is reflected in whether they provide design optimization suggestions before quoting, helping customers avoid common pitfalls. Engineering support capability is a key indicator for differentiating supplier levels.

2. Quality System Certification Ensures Reliability

Whether a supplier holds certifications such as ISO 9001:2015 and IATF 16949 directly relates to process reliability. The value of ISO 9001 certification lies in providing a structured quality management system, ensuring that each prototype is produced according to established, reliable standards, which is crucial for batch consistency.

3. Technological Breadth and Communication Efficiency

Partners should possess a variety of technologies (such as CNC, 3D printing) and material options to meet different needs. At the same time, communication efficiency is reflected in responsiveness and transparency. The lowest quote may mean sacrificing quality or lacking support, ultimately leading to higher overall costs.

What is the Realistic Cost and Timeline for a Professional Prototype?

Understanding the true cost and timeline of rapid prototyping helps in reasonable budget planning. This section transparently breaks down the constituent elements, eliminating unrealistic expectations.

l Cost Components: Materials, Labor, and Post-processing: The cost structure of rapid prototyping mainly includes material costs, equipment labor hours, post-processing (such as polishing, painting), and quality inspection. Complex geometries increase programming and processing time, thus driving up costs. A transparent online rapid prototyping quoting system allows customers to clearly understand the budget breakdown before making decisions.

l Typical Timeline: From a Few Days to a Week: Technology selection directly affects the cycle time: 3D printing usually takes 1-3 days, CNC machining takes 3-7 days, and vacuum casting may take longer (including mold making). Variables such as part complexity, material availability, and tolerance requirements will also adjust the timeline. Planning ahead can avoid project delays.

l Influencing Variables and Optimization Strategies: Core variables include design complexity, material selection (e.g., metal is more expensive than plastic), and tolerance requirements. Through DFM (Design for Manufacturability) optimization, costs can be significantly reduced and lead times shortened. For example, simplifying features can reduce CNC machining paths and improve efficiency.

Can a Prototype Seamlessly Transition to Mass Production?

Rapid prototyping is not only used to validate designs but should also pave the way for mass production. This section discusses how to build a bridge from prototype to mass production.

1. Process Parameter Validation and Data Transfer

Process parameters (such as injection molding temperature, cutting speed) validated during the prototyping phase provide reliable data for mold development, reducing mass production risks. Rapid prototyping services should record these parameters toensure consistency.

2. The Importance of Small-Batch Trial Production

Small-batch trial production using vacuum casting or rapid tooling allows for market validation and supply chain preparation, reducing the risk of large-scale investment. A strategic prototyping partner can ensure a smooth transition from design to mass production. Learn more about comprehensive solutions from prototyping to production.

3. Design Iteration and Risk Reduction

Iterations during the prototyping phase help optimize the design, avoiding costly modifications during mass production. For example, validating assembly interfaces through rapid prototyping ensures component compatibility during mass production.

Conclusion

The key to strategically utilizing rapid prototyping technology lies in treating it as an indispensable risk management and optimization step in the product development process. By choosing the right technology, emphasizing upfront DFM analysis, and collaborating with partners with solid quality systems and engineering capabilities, companies can significantly reduce overall development costs and accelerate time to market.

FAQs

Q: Is a free quote and DFM analysis really free?

A: Yes, professional rapid prototyping service providers usually offer free quotes and DFM analysis as part of their customer support. This helps identify potential problems before project launch, avoiding subsequent cost overruns.

Q: How long does it typically take to receive a quote after submitting files?

A: For most projects, a detailed quote, including DFM feedback, will be received within 8 business hours after submitting the files. Complex parts may require a longer feasibility study to ensure accuracy.

Q: Will design changes suggested in a DFM report alter the part’s function?

A: No, DFM suggestions aim to optimize manufacturability, such as adjusting wall thickness or tolerances, without affecting core functionality. These changes are based on engineering best practices to improve prototype success rates.

Q: What quality assurances come with a prototyping order?

A: Orders typically include quality certificates, such as material reports and dimensional inspection data. Suppliers holding certifications like ISO 9001 ensure process control, guaranteeing that prototypes meet specifications.

Q: How do you handle urgent prototyping requests?

A: For urgent requests, suppliers may offer expedited services, shortening lead times through priority scheduling and process optimization, usually delivering within 1-3 days, but this may incur additional costs.

Author Bio

The author is a manufacturing specialist at LS Manufacturing, a company that helps engineers and researchers solve complex component challenges in the aerospace, medical, and automotive industries. The team holds certifications such as ISO 9001, IATF 16949, and AS9100D, and is committed to ensuring customer success through precise rapid prototyping services. Upload your 3D files today to receive a free quote with detailed DFM feedback and experience the efficiency of getting it right the first time.