Direct Acting vs Pilot Operated Solenoid Valves: What’s the Difference?

✔️ What these two valve types do — and why it matters for automation

✔️ Key difference: direct acting opens via coil alone, pilot uses line pressure

✔️ Pressure, response speed, cost — side-by-side comparison

✔️ Where I’ve used each type in real systems

✔️ Includes wiring notes, common mistakes, and selection tips

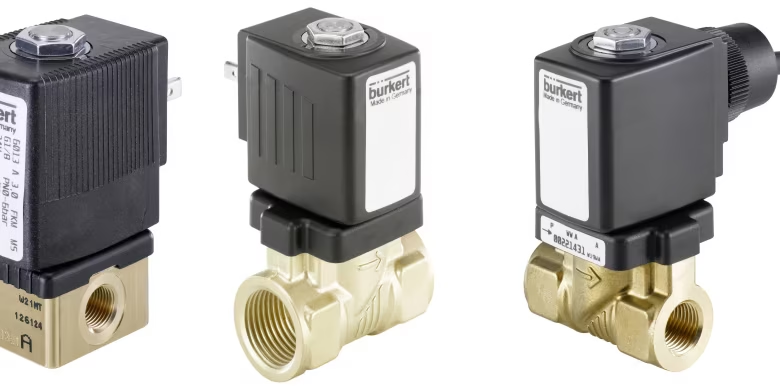

What Is a Direct Acting Solenoid Valve and How Does It Work?

When I’m troubleshooting flow systems or specifying valves for tight-tolerance applications, direct acting solenoids are often my go-to — especially when the line pressure is low or response speed matters.

Here’s why:

- Direct lift mechanism: A direct acting solenoid valve uses only the magnetic force generated by its coil to lift the valve plunger. There’s no pilot stage or pressure assist involved — just the coil energizing, lifting the plunger, and opening the flow path. Simple and fast.

- Works at zero differential pressure: This is one of the biggest advantages. If your system doesn’t have any inlet pressure — like in a dosing pump line or a drain control loop — a pilot-operated valve won’t open. But a direct acting valve will. That makes it ideal for gravity-fed systems or suction-side control.

- Best suited for low flow rates and clean fluids: I’ve installed these in everything from lab water dispensers to clean-in-place (CIP) rinse lines in food processing. They’re great for low-viscosity fluids like water, solvents, and even some gases — as long as the flow rate isn’t too high.

- Simple internals = reliable operation: With fewer components inside (no diaphragm, no pilot passage), these valves are less prone to clogging or mechanical failure. That’s critical in environments where maintenance access is limited.

Where I use them most:

- Lab-grade water and chemical metering skids

- Purified water dispense systems

- Compact automation panels for cleanrooms

- Any setup with intermittent flow or pulsed dosing

If you’re specifying valves for precise low-flow tasks or designing a circuit with limited pressure differential — direct acting is the smart choice. Just make sure to match voltage, coil duty cycle, and fluid compatibility.

What Is a Pilot Operated Solenoid Valve?

A pilot operated solenoid valve is a two-stage design that uses the system’s own line pressure to do the heavy lifting. Instead of relying on the solenoid coil alone to open the main valve, this type of valve first opens a small internal passage — the pilot orifice — when the coil is energized. That small shift allows the pressure on one side of the diaphragm or piston to drop, and the main flow path opens due to the pressure difference.

This design allows the valve to control much higher flow rates and larger pipe sizes than a direct acting solenoid could manage alone. It’s why I often recommend pilot operated valves for industrial applications like cooling systems, compressed air networks, or process lines running at several bar of pressure.

But here’s the catch — these valves require a minimum pressure differential to operate. If there isn’t enough upstream pressure (for example, in gravity-fed systems or low-pressure tanks), the valve won’t open fully, or at all. That’s something I’ve seen trip up junior techs during commissioning.

So, while they’re excellent for high-volume, steady-pressure systems, they’re not ideal for ultra-low pressure or zero-pressure startup lines. Understanding that pressure dependency is critical when choosing between direct acting and pilot operated solenoid valves.

Direct Acting vs Pilot Operated: Key Differences Compared

Before deciding which solenoid valve type to use, it’s important to understand how direct acting and pilot operated valves differ in real-world performance. From my experience setting up everything from compact dosing skids to full-scale HVAC loops, the choice isn’t just about cost — it’s about pressure conditions, flow requirements, and how quickly the system needs to respond.

| Feature | Direct Acting | Pilot Operated |

| Minimum Pressure Required | None | Yes (e.g., 0.5–1 bar) |

| Flow Capacity | Low to medium | Medium to high |

| Response Time | Fast | Slower |

| Complexity | Simple | More complex |

| Use Case | Dosing, sampling, lab equipment | Water lines, HVAC, large process valves |

In short, direct acting valves are your go-to for simplicity and fast response at low pressures, while pilot operated valves excel in larger, pressurized systems where flow volume and energy efficiency matter more. I always recommend reviewing your system’s pressure conditions and actuation needs before committing to one over the other.

When to Use Direct Acting Valves (And Why)

In my field experience, I’ve found that direct acting solenoid valves are the go-to choice when you’re working in systems that don’t have built-in pressure differential — especially in small-scale setups or applications with very low or even vacuum-level pressure.

Since these valves rely purely on the coil’s electromagnetic force to lift the plunger and open the orifice, they work right down to zero pressure, which is a huge advantage in precision dosing, sampling, or clean lab systems. I’ve installed Burkert solenoid valves in vertical dosing lines where gravity is the only assist — and in those situations, pilot-operated valves simply wouldn’t function. The direct acting type gave me consistent, snappy operation with no lag or hunting.

They’re also ideal for low-flow applications where tight control and fast response matter more than raw throughput. Think lab dosing skids, diagnostic analyzers, or pharmaceutical washdown systems.

When you need reliability without pressure headroom — or just want something simple with minimal failure points — a direct acting Burkert solenoid valve is often the smartest solution.

When to Use Pilot Operated Valves (And Why)

In systems where flow volume is significant and pressures are higher, pilot operated solenoid valves become the better fit — both in terms of efficiency and long-term reliability. Unlike direct acting types, these valves use a two-step mechanism: the coil opens a small pilot orifice, and the system’s own line pressure does the heavy lifting to open the main valve. That means you save electrical energy, reduce wear, and can manage larger pipe diameters without upsizing the solenoid itself.

I usually reach for a Burkert solenoid valve with pilot operation when I’m working on 1-inch or larger water lines — especially in irrigation panels, commercial HVAC systems, or industrial process cooling circuits. In these cases, pilot valves are not only more cost-effective over time, but they also offer smoother flow transitions and better performance under pressure.

Just keep in mind, they do require a minimum pressure differential to operate (usually 0.5 to 1 bar), so they won’t work in vacuum or zero-pressure lines. But when you have stable upstream pressure, a pilot operated Burkert valve is a solid choice — I’ve seen them run for years in tough plant conditions with minimal maintenance.

Common Installation Mistakes (Field Lessons)

When you’re dealing with solenoid valves — especially pilot operated types — the devil’s in the details. I’ve seen even experienced techs trip up on things that look obvious in hindsight, but aren’t when you’re under pressure to get a system online.

One of the most common issues I run into is not having enough pressure differential to operate a pilot valve. These valves rely on line pressure to open the main orifice, so if you’re dealing with low-pressure lines or startup conditions without flow, they simply won’t work. Always check the spec sheet — most pilot operated models need at least 0.5 to 1 bar of pressure to open fully.

Another surprisingly frequent mistake? Installing the valve upside down. Yes, it happens — especially with inline-mounted valves that don’t clearly label orientation. With pilot valves, incorrect orientation can prevent the internal diaphragm from sealing or opening properly, which means no flow and a lot of head-scratching during troubleshooting.

I’ve also had callbacks because someone forgot to clean the inlet strainer. Small debris or even teflon tape can jam the plunger or pilot orifice, causing the valve to stick shut or leak slightly. It’s a tiny detail, but it can take down an entire system — especially in fluid-sensitive environments like pharma or food plants.

And here’s one I never skip anymore: purging air and flushing lines before applying power to the coil. Debris, trapped air, or even residual cleaning solution can interfere with actuation. One plant I worked in had repeated valve failures on a CIP return line — turned out they were energizing the coils before the line was ever properly flushed. Lesson learned.

Pro tip: “Always purge air and debris before powering the coil — trust me, it saves callbacks.”

How to Choose Between Direct Acting and Pilot Operated

Choosing between a direct acting and a pilot operated solenoid valve comes down to more than just line size. I’ve made this call dozens of times in field installs — and it always starts with matching the valve to the actual operating conditions. Here’s how I recommend approaching the decision:

1. Check Line Pressure and Flow Requirement

If the system operates at low or zero pressure (like gravity-fed tanks or vacuum systems), go with a direct acting valve. Pilot operated valves rely on line pressure to function and will stay closed if pressure’s too low.

2. Determine if Pressure Is Available at Startup

For systems that need to actuate immediately on power-up — especially without established pressure — direct acting is the safer bet. Pilot valves often need pre-built line pressure just to begin operating.

3. Match Fluid Type and Cleanliness

If you’re working with clean water, air, or neutral gases, either type can work. But for thicker fluids, contaminated lines, or sensitive dosing applications (think pharmaceuticals or lab equipment), direct acting valves offer better reliability and fewer clog points.

4. Consider Cycle Speed

Need fast, snappy switching? Direct acting solenoid valves are typically quicker because the coil directly moves the plunger without waiting for pilot pressure dynamics.

5. Review Voltage, Coil Size, and Duty Cycle

Pilot operated valves often require smaller coils and less power over time, which can be a factor in high-duty or battery-powered systems. Direct acting valves draw more current but give you direct, instant actuation.

This checklist has helped me narrow down valve choices on everything from clean-in-place lines to HVAC loops. If you’re ever unsure — start with the pressure spec and build from there.