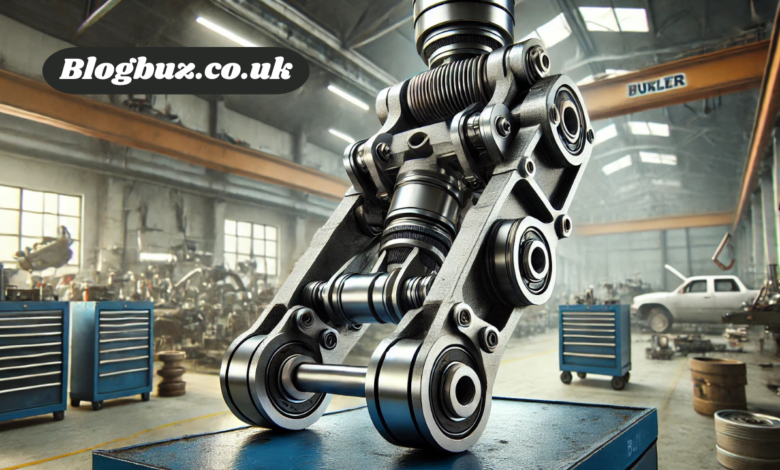

Butler G4B25 22: A Comprehensive Guide to the Versatile Swing Arm for Industrial Applications

The Butler G4B25 22 swing arm has gained considerable attention in automotive and heavy machinery due to its versatile design, durability, and performance capabilities. This swing arm is widely used in automotive repair, industrial machinery, and construction equipment and is designed for applications where strength, stability, and precision are required. This article explores the features, benefits, applications, and maintenance requirements of the Butler G4B25 22, providing an in-depth look at why it’s a go-to choice for professionals in multiple sectors.

What Is the Butler G4B25 22 Swing Arm?

A swing arm is a mechanical component designed to provide stability and controlled movement, often used in equipment that requires repetitive or precision-driven motion. The Butler G4B25 22 model is engineered with high-grade materials, typically steel or aluminum, which provide durability and strength without compromising flexibility. This swing arm’s innovative design allows it to handle substantial loads and withstand challenging environments, making it ideal for various applications, from vehicle lifts to manufacturing lines.

Key Features of the Butler G4B25 22 Swing Arm

- Robust Construction

- The G4B25 22 swing arm is constructed with high-strength materials, ensuring it can bear heavy workloads while maintaining structural integrity. This robust build allows it to handle repeated stress, making it suitable for demanding heavy machinery and industrial equipmentapplications.

- Precision Bearings

- Equipped with high-precision bearings, the Butler G4B25 22 offers smooth, controlled movement, reducing wear and enhancing the longevity of the machine it supports. These bearings are essential for applications that require fine articulation, such as tire changers or vehicle lifts, where stability and movement are critical.

- Advanced Articulation

- The swingarm is engineered to provide advanced movement capabilities, allowing it to pivot and move in various directions as needed. This flexibility makes it ideal for precision tasks, such as industrial production procedures and vehicle maintenance, where controlled movement is essential.

- Enhanced Load Capacity

- One of the stand-out features of the G4B25 22 swing arm is its ability to handle substantial weight without compromising performance. This makes it suitable for heavy-duty and lightweight operations, as it can maintain stability under high stress and frequent use.

- Corrosion Resistance

- A special coating on the Butler G4B25 22 protects it against corrosion, enhancing its durability in environments where it may be exposed to moisture, chemicals, or harsh conditions. This feature makes it ideal for industrial settings, extending the component’s life and reducing maintenance costs.

Applications of the Butler G4B25 22 Swing Arm

Automotive Industry

The Butler G4B25 22 is a valuable component in automotive workshops, particularly for tasks involving vehicle lifts and tire changers. Its precision and durability allow it to support vehicle weight securely, ensuring smooth and efficient operation during tire changes and repairs. The stability offered by this swing arm also improves safety and control for automotive technicians.

Industrial Machinery

The swingarm is a popular choice in the industrial sector, where machinery often requires parts that can handle repetitive movement and significant loads. The G4B25 22 swing arm enhances machinery efficiency and longevity by providing stable and controlled motionin assembly lines, manufacturing equipment, and robotic arms.

Recreational Vehicles

For motorcycles, bicycles, and other recreational vehicles, the Butler G4B25 22 swing arm enhances ride stability and control, particularly during high-speed cornering and acceleration. It plays a critical role in suspension systems, offering improved handling and performance, which are essential for rider safety and comfort.

Construction Equipment

The G4B25 22’s high load-bearing capacity and durable construction make it ideal in construction machinery where reliable, heavy-duty components are necessary. This swing arm manages movement and supports structural components, from cranes to loaders, enhancing operational efficiency and safety.

Benefits of the Butler G4B25 22 Swing Arm

- Improved Stability

- The G4B25 22 provides excellent stability, minimizing issues like tipping or imbalance during operation. This stability is crucial in automotive and heavy machinery applications, where safety is paramount.

- Enhanced Durability

- With its corrosion-resistant coating and robust materials, this swing arm is designed to withstand harsh environments and prolonged use. Because of their durability, fewer replacements are required, making it a cost-effective solution in the long run.

- Versatility Across Applications

- The adaptability of the G4B25 22 swing arm makes it a popular option in many different sectors. Its ability to support various machinery and equipment adds flexibility, allowing companies to use it in diverse applications without requiring specialized components.

- Cost Efficiency

- The longevity and reliability of this swing arm contribute to reduced maintenance costs and downtime. Its initial investment is balanced by its durability, reducing the need for replacements and repairs over time.

Installation Guide for the Butler G4B25 22 Swing Arm

Installing the Butler G4B25 22 is straightforward, but proper alignment and adherence to torque specifications are essential to ensure optimal performance. Here’s a brief step-by-step guide for installation:

- Prepare the Workspace and Tools

- Ensure the installation area is clean, and gather tools such as wrenches, screwdrivers, and a torque wrench. This preparation helps streamline the installation process.

- Remove Existing Components

- If replacing an old swing arm, carefully detach it by loosening bolts and removing fasteners. Keep parts organized to facilitate a smooth reinstallation.

- Align the Swing Arm

- Position the G4B25 22 swing arm carefully, aligning it with the mount points. Proper alignment prevents strain and ensures that the swing arm operates smoothly.

- Secure Fasteners

- Tighten bolts and screws according to the manufacturer’s torque recommendations to avoid loosening during operation. Proper torque settings help maintain stability and durability.

- Test the Swing Arm Movement

- After installation, test the swing arm’s movement to confirm that it operates without restriction. Adjust as needed to achieve smooth, controlled motion.

Maintenance Tips for the Butler G4B25 22 Swing Arm

Regular maintenance is recommended to ensure the swing arm’s longevity and performance. Here are some essential maintenance steps:

- Routine Lubrication

- Regularly lubricate the bearings and moving parts with high-quality lubricants to reduce wear and promote smooth movement. This is especially important for high-use applications.

- Inspect for Wear and Tear

- Periodically check for cracks, bending, or damage, especially in high-stress applications. Future expensive repairs can be avoided with early problem discovery.

- Clean Regularly

- Dust and debris can accumulate on the swing arm, leading to potential corrosion. Clean the swing arm periodically, especially in environments where it is exposed to dust or moisture.

- Check Fastener Torque

- Vibration and constant use can loosen bolts over time. Regularly check and tighten fasteners to ensure the swing arm remains securely attached and functional.

Conclusion

The Butler G4B25 22 swing arm is a reliable, versatile component supporting various automotive, industrial, and recreational applications. Its durable design, advanced articulation, and high load-bearing capacity make it a valuable addition to any machinery requiring stable and controlled movement. With proper installation and maintenance, this swing arm can significantly improve the functionality and durability of its supporting equipment. For businesses seeking an efficient, long-term solution, the Butler G4B25 22 swing arm is an excellent investment in quality and performance.

You May Also Read: Part Number 87100501a: Essential Information, Applications, and Sourcing Guide