Acrylic Machining Services: Precision Acrylic CNC Machining for Plastic Fabrication

Understanding Acrylic and Its Properties

Acrylic, or polymethyl methacrylate (PMMA), is well-known as a versatile transparent thermoplastic material because it is durable and clear. It is a polymer made from acrylic acid and its derivatives and can be formed into a wide range of products. It is often used in place of glass because it is lighter and more impact-resistant. It comes in a range of colors, finishes and thicknesses, and can be easily cut, machined or thermoformed to the desired shape.

If you are looking for more information about Acrylic Machining Services – Hopeful, go here right away.

Advantages of Acrylic Over Other Plastics

When put next to other types of plastics, Acrylic exhibits certain unique advantages. First, it has remarkable optical clarity, as it transmits more light than standard glass, which is very useful in applications where transparency or light diffusion is needed. Second, it has substantial advantages in weight over glass, which can be beneficial in structural or transport applications. Third, Acrylic has a high resistance to UV radiation and weathering which aids in ensuring longevity without any yellowing or brittleness over time. In addition to these advantages, acrylic also has strong impact resistance, which makes it more durable than many plastics, and scratch resistance, which allows it to be polished to restore clarity and extend its usability.

View Acrylic Machining Services for sale – Hopeful for More Details

Acrylic’s Most Popular Uses

Because of the flexibility and durability of the thermoplastic acrylic, it is used in many industries. Some of the most notable uses of acrylic include signboards, display cases, and point-of-purchase displays. These uses of acrylic take advantage of the material’s optical clarity and beauty. These industries utilize acrylic in the manufacture of aquariums and protective glasses, making use of acrylic’s strength and optical characteristics. These industries use acrylic for its lightweight and impact-resistant properties for windows, lenses, and interiors in the automotive and aerospace industries. It is also used in medical appliances, lightning devices, and in furniture and home decorations, which shows its multifunctionality.

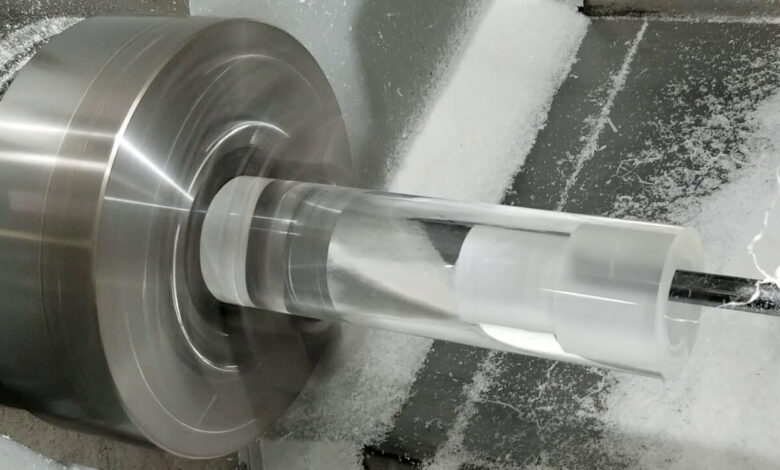

Acrylic CNC Machining Services

CNC (Computer Numerical Control) machining is an exact form of manufacturing that scans computer-aided instructions,/tools for the shaping and fabrication of materials such as acrylic into complex parts. By following pre-established blueprints, CNC equipment can obtain precision for tasks across many sectors. This technology is now widely preferred for acrylic fabrication as it gives unprecedented accuracy and speed as compared to older machining methods.

Types of Acrylic Machining Techniques

Cutting: Acrylic sheets are shaped and sized to specific measurements using CNC Routers and laser cutters. Laser cutting is the most common method for achieving seamless and shiny edges.

Milling: CNC milling is the removal of material from a shaped acrylic workpiece to improve its functionality, making it more complicated. It is capable of making very accurate grooves, holes, and cavities.

Engraving: Acrylic surfaces can have intricate designs, specific texts or ornamental features engraved onto them. This form of CNC engraving is popular for sign and display items.

Finalising processes: CNC methods such as flame polishing or buffing can be used to raise the aesthetic value of sharpened edges to a smooth and clear surface, like glass. This is a common step done after machining.

Advantages of CNC Machining Acrylic

CNC machining provides exceptional accuracy and ensures every acrylic part is manufactured to prescribed tolerances for optimal operational efficiency.

The automation of processes in CNC machining saves time in comparison to prototyping and large-scale manufacturing. Throughput is also increased, making CNC machining ideal.

CNC machines yield uniform results. Each acrylic component produced will meet the exact specifications granted, no variances.

It is often very difficult and in some cases, impossible to manually achieve intricate and multi-faceted designs. CNC machining acrylic makes this a possibility.

CNC machining provides a reduction in material waste, performs tasks with minimal manual labor, and attains a high production pace. All of these elements together create a cost-efficient approach to acrylic fabrication.

From the automotive industry to consumer goods, CNC machining provides acrylic fabrication for high-quality products, making it widely available.

Plastic Machining Capabilities

Summary of Services Related to Plastic Machining

With the advancement of technology, plastic machining refers to the intricate processes involved in shaping and modifying plastic materials to meet particular industrial needs. These processes include cutting, polishing, vertical machining, turning, and even drilling. These services are necessary in sectors such as aerospace, electronics, manufacturing, and the medical field. In these industries, there is always a need for high-quality plastic components. Thanks to modern machining solutions, strict tolerances are increasingly possible to meet.

Acrylic and Other Plastics Machining Differences

Acrylic machining is well-respected for its clarity, being lightweight, and for how it withstands harsh weather conditions. While polycarbonate, ABS, and POM (Polyoxymethylene) Plastics offer their advantages, they lack in comparison to Acrylic in regard to Optical Transparency. This makes Acrylic an excellent candidate for the construction of display panels and lenses. On the other hand, polycarbonate is more durable and impact-resistant, making it more desirable in certain uses. Other plastics, such as PEEK and PTFE, excel in uses that require high temperature and chemically resistant materials, but where acrylic shines is in its aesthetic value and uncomplicated machining. Every plastic material has specific advantages and disadvantages, and the optimal selection depends on the intended use, mechanical specifications, and environmental conditions.

Precision Machining in The Plastic Industry

Precision machining refers to the processes that include shaping, carving, turning, vacuum stamping as well as other processes to create parts that fulfill functionality requirements with typically very tight tolerances and merging forms of high complexity. With the aid of the CAD CAM software widely used today, complex designs can be effortlessly executed with minimum material loss, which is a necessity in the medical and aerospace industries, as the plastic parts used have to be precise in their functionality and safety. In addition, precise plastic machining aids in maintaining product consistency, manufacturing scalable production runs, working with different types of plastics, and providing consistent quality. The capabilities of the plastic industry in terms of innovation and application has greatly increased with the introduction of precision machining since the plastic industry can now be affordably and accurately used for prototyping and mass production without extensive manufacturing time.

Fabrication of Acrylic Parts

Procedures Necessary for Acrylic Parts Machining

Acrylic components fabrication follows a sequence of rigorous and meticulous steps. Such steps include laser cutting for sheet separation from a bulk piece as well as CNC machining for intricate designs and tolerances. There are also other auxiliary processes, such as heat bending for curvilinear shapes and solvent bonding for strong and seamless joining of two or several components. Polishing is done as a final step for all processes to enhance smoothness and clarity. If all the processes are done accurately, it guarantees the aesthetic and functional value of the finished product.

Acrylic Component Manufacturing: A Tailored Approach

Acrylic components refer to a diversified portfolio that includes various parts that can be manufactured for applications in different industries. As the term ‘fabrication’ suggests, custom part manufacturing starts with a design that meets the client’s needs. In most cases, these specifications can be fulfilled with the aid of sophisticated design applications. In some cases, it might be required to create a prototype that demonstrates full functionality, and only then proceed to scale-up production. A fundamental part of custom manufacturing is CNC machining due to its extensive range of part size and shape variability. Additionally, custom anti-glare and anti-UV coatings can be applied to increase the functionality of the component. Through this cooperation, the client requirements are met and the design is functionally optimal and economical.

Quality Assurance with a Focus on Functionality

In custom acrylic manufacturing, precision, functionality, and optical-grade transparency work in a battle to achieve an industry-leading part.

Custom acrylic manufacturing starts with a design that meets the client’s needs. In most cases, these specifications can be fulfilled with the aid of sophisticated design applications, and only then proceed to scale-up production. In some cases, it might be required to create a prototype that demonstrates full functionality. For mass production, advanced metrology instruments are required that comply with precision requirements, for example, coordinate measuring machines (CMMs) as parts of advanced precision systems are marked with industry marking systems. During the production process, each stage of isolation, including marking and stress testing, ensures the production cut meets optical property requirements. Adhesive strength and thermal stability are key in determining the invisibility seams in parts and determining the parts’ transparency, which ensures these factors are preserved.

Requesting a Quote for Acrylic Machining Services

Details Needed to Acquire a Quote

When acquiring a quote for acrylic machining services, it is necessary to give precise information so that the estimate is accurate. A few of the details include the material type, for instance, if it is cast or extruded acrylic, the required dimensions, tolerances, and the specified design features that need to be executed, such as pocketing, contouring, or engraving. Moreover, providing a CAD file or technical drawings accelerates the quoting process and minimizes the chances of miscommunication. It also helps avoid back and forth. Expectations on volume, lead times, and surface finishing also need to be described and these factors tend to influence production planning.

Factors Affecting the Price of Acrylic Machining

Pricing of acrylic machining services is impacted by a number of variables. A key one among these is the complexity of the design, which impacts the time and tooling needed for production. Small tolerances or intricate geometries may require sophisticated machining or lengthened cycle times. Also, the material picked, its thickness and grade, and the presence of secondary operations like polishing, threading, or assembling impact the cost. Volume is also a key determining factor, where there tends to be economic advantages for larger orders.

Commitment to Quality in CNC Services

A CNC machining company will focus on QMS in all parts of the operations to ensure they will meet the needs of their customers. This covers all processes like the application of accurate CNC equipments, strict quality control in all processes, and compliance with the minimal requirements like ISO 9001. The usage of modern metrology equipment guarantees the measurement of parts and surfaces, their geometric accuracy, and the performance of the material as well. The application of best practices in the sector and with the help of qualified staff, acrylic parts made to the customers’ order are provided through the CNC Services.