Aluminum CNC Machining Service: A Complete Guide to Precision Manufacturing

CNC Machining Process Overview

Introduction to CNC Machines

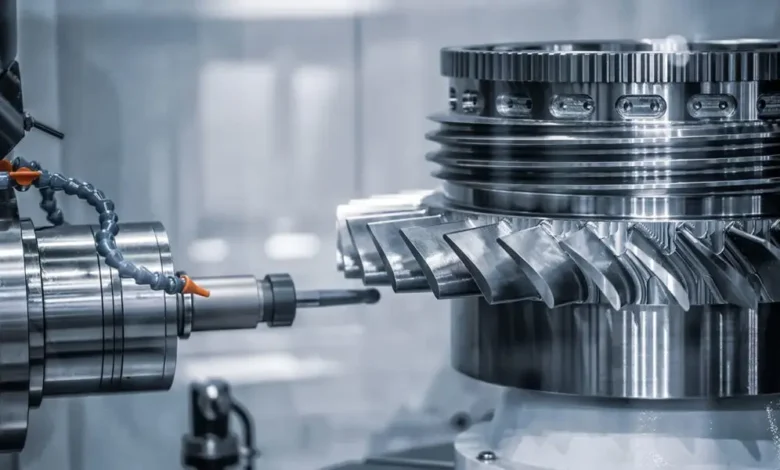

CNC systems control cutting operations using computers that guide the cutting tools along specific routes. Automated systems read and decode design files made with CAD software and execute machine operations. This yields parts that are consistently produced and conform to specified tolerances without variability.

If you are looking for more information about Aluminum CNC Machining Service – Kingsun, go here right away.

Modern CNC machine designs feature advanced servo motors and sensors that track cutting operations alongside feedback systems. Technologies such as these guarantee that critical geometric features are preserved and that the cutting methods used during machining are the best suited.

For more in-depth information, you should view the Aluminum CNC Machining Service – Kingsun.

How CNC Machining Works

Every CNC machining cycle starts with a digital design file that specifies the geometry and features of the part. This design file is processed with CAM software which creates G-Code, a machine language that commands the CNC systems with tool operations such as movement, rotation speeds, and feed rate.

The CNC machine clamps the aluminum stock part to a vise. It employs cutting tools that are fixed to the spindle to machine the part as per the design software instructions. Furthermore, the CNC machine has a coolant system that keeps the machining temperatures in check and eliminates chips during the machining cycle.

Types of CNC Machining Processes

There are a variety of processes that are grouped these days under the CNC machining umbrella to meet the diverse needs of the customers and market dynamics, as discussed below:

CNC Milling employs a rotary cutting tool to eliminate stock material. In this process, the workpiece does not move, but the tool is capable of moving in several axes, enabling the creation of complex shapes and structures.

In the CNC Turning process, a cutting tool, which is fixed in place, is used to shape material on a rotating workpiece. This process primarily focuses on the production of cylindrical components.

In the CNC Drilling process, specialized drill bits fabricate exact holes. Multi-axis machines are capable of drilling both at an angle and at varying depths.

In CNC Grinding processes, the use of abrasive wheels greatly enhances the attainment of smooth surface finishes and tight tolerances.

Understanding Aluminum CNC Machining

Why Choose Aluminum for CNC Machining?

Aluminum has a special combination of characteristics that makes it valuable in CNC machining. Its low density makes it easy to cut and form while providing strength to weight ratios that bests several engineering materials. The excellent thermal conductivity of aluminum aids in dissipating heat during machining, thus reducing tool wear and improving the surface finish of the machined component.

The aluminum CNC machining service reduces the need for protective coatings due to the material’s excellent corrosion resistance, which aids in eliminating the need for protective coatings in several applications. Its good electro-conductivity makes it appropriate for electronic apparatus as well as for heat sinks.

CNC Machining Aluminum: Benefits and Applications

The aluminum CNC machining service enhances efficiency and productivity in manufacturing processes. The materials’ good machinability makes it possible to use high cutting speeds and feeds, improving cycle times and lowering production costs. The ability of aluminum to retain tight tolerances makes it a good fit for precision components.

These components and housings are most commonly used in:

Parts that are lightweight and high-strength for the aerospace industry.

Suspension components and engine blocks of the automotive industry.

Order of electronic components and housings, heat sinks.

Parts of medical devices which are biocompatible.

Parts of industrial machinery that need corrosion resistance.

Aluminum used for CNC Machining

Different alloys of aluminum have different applicational characteristics ,such as:

Some alloys demonstrate better corrosion resistance, while some are easily machinable, such as 6061 aluminum. It can be easily welded and worked on, while providing good structural strength.

7075 Aluminum is of particular interest in the aerospace industry due to its superior strength-to-weight ratio. Although this alloy requires precision in its heat treatment processes, it is forgiving during machining.

Though 2024 Aluminum is less resistant to corrosion in comparison to other alloys, it is still widely utilized in the aerospace industry due to its outstanding strength characteristics.

Aluminum 5052 is outstanding in its corrosion resistance and formability. Furthermore, it is well-suited to marine environments and the manufacture of metal sheets.

Precision and Tolerance in CNC Machining

Importance of Tolerance in CNC Machining

Tolerance delineates the permissible deviation in a part’s dimensions and critically affects the component’s functionality and assembly requirements. Ideal fitting components with tight tolerances enhance machining precision and functionality of the components. However, requires a balance with performance requirements and manufacturing costs within economics.

Achieving tolerances with manual machining is nearly impossible; it can only be achieved with CNC machining. Though maximum precision requires rigor in the machine’s capabilities, tools, and other external factors.

Achieving High Precision in Machined Aluminum

Factors impacting precision in CNC machining of aluminum include:

Machine Rigidity critically affects the tool’s position, which in turn affects maintaining stability under the prevalent cutting forces. Machines with robust structure supports provide rigid frameworks, which provide increased slicer stability and more accurate machining.

Tool Selection impacts finishing accuracy. Elaborate polishing and proper sharpening reduce the forces directed to cutting and the resultant heat generated.

Well-designed and executed work-holding systems ensure holding the workpiece part without introducing additional distortion.

Control systems consistently provide the appropriate temperature ranges. Exceeding the set ranges results in additional thermal expansion with degradation in dimensional accuracy.

Common Tolerances in CNC Machining Services

Within the domains of CNC aluminum machining, general tolerances are set at minus 0.005 inches and plus 0.127 mm. Precision requirements can be set at minus 0.001 inches and plus 0.025 mm. In some scenarios, precision surpasses expectations with a range of minus 0.0005 inches and 0.013 mm.

The capabilities for tolerances differ with regard to the geometry of the part, its dimensions, and the processes used for machining. Straight linear features are likely to achieve greater accuracy than rounded features, angled elements, or multifaceted profiles.

Surface Finish of Machined Aluminum

Factors Affecting Surface Finish

A surface finish is influenced by multiple machining parameters and conditions. Cutting speed, feed rate, and depth of cut have direct effects on surface texture. Finish quality is affected by tool geometry and is particularly influenced by the tool’s nose radius and the sharpness of the cutting edge.

The surface finish of the workpiece is also influenced by its material properties. If not managed with the right speed, feed rate, and coolant, aluminum’s propensity to build up on cutting edges results in surface finish imperfections.

Common Surface Finish Techniques in CNC Machining

Improvements on the aluminum surface finish can be achieved by:

Conventional machining can provide surface finishes of 32-125 microinches Ra with optimized cutting parameters.

Finish Machining operations, creating finishes within 16-32 microinches Ra by utilizing high-speed spindles coupled with light cut depths.

Some secondary operations of surface finishing, like polishing and bead blasting, can be used to improve surface quality for specialized applications.

Selecting the Most Appropriate Surface Finish for your Project

The selection of surface finish must take into consideration the functional and usability requirements alongside the cost. While cosmetic applications may demand mirror-like finishes, structural components that are not visibly accessible can be rough. Consider wear resistance, corrosion protection, surface finish, and assembly requirements.

CNC Milling and Machining Capabilities

Overview of CNC Milling Services

CNC milling services include different configurations and capabilities of machines. Vertical mills have the spindle over the workpiece and are useful for face milling and drilling. While horizontal mills do place the spindle in horizontal orientation, they are also better at chip removal during heavy cutting operations.

A single setup may integrate drilling, milling, and at times, turning operations, which are performed by a machine called a machining center. Such machines are characterized by the presence of automatic tool changers and several workholding positions for enhanced productivity.

5-Axis CNC Machining: Benefits and Uses

Concurrent with the adoption of 3-axis movement, 5-axis CNC machining introduces some rotational capabilities. More setups are necessary for the completion of complex geometries, which this technology simplifies further by removing the need for repositioning, setup time, and accuracy.

Turbine blades, impellers, and even complex brackets with some angled features are the most basic that the 5-axis can work on. Better surface and tool life are the results of maintenance of optimal tool angle during the cutting process.

Custom CNC Services for Unique Projects

Custom CNC services address specialized requirements that standard processes cannot accommodate. These services may include:

- Prototype development for new product designs

- Low-volume production runs with quick turnaround

- Specialized fixturing for unusual part geometries

- Integration of multiple manufacturing processes

Choosing the Right CNC Service Provider

Evaluating Machine Shops for CNC Services

Choosing a CNC service provider involves meticulous consideration regarding numerous criteria. Businesses often encounter gaps where a provider’s machine capability does not meet the customer’s size, tolerance, or complexity requirements. Standards such as ISO 9001 certification indicate reliable processes.

Industry experience, especially in aluminum machining, adds considerable value since knowing the material contributes positively to the outcome. It is essential to cross-check the shop’s equipment list to ensure that the available machine and their corresponding tools fulfill the requirements of the project.

Understanding Pricing and Turnaround Times

The machining price for CNC services increases with complexity, precision, material requirements, and volume. Standard tolerances are cheaper than complex geometries requiring tight tolerances.

Material availability, shop capacity, and complexity affect the turnaround time. These factors, along with volume, determine CNC service provider capacity. Additional fees are often required for faster service, especially for critical projects.

Maximizing Success with Aluminum CNC Machining

Aluminum CNC machining serves a wide range of industries due to its adaptability and the lightweight precision parts it offers. The complexity of a project is framed within factors like material properties, machining processes, and quality considerations . Machined parts are driven by specific target objectives; factors such as functionality, expenses, and efficiency are all important.

Choosing the right service provider is a critical component for project achievement as it directly relates to service capability and quality control steps. High-quality output hinges on the exact communication of standards and the fulfillment of stated objectives. Let us provide you with a quotation for aluminum CNC machining and help you leverage durability and efficiency for precision parts.