Essential Maintenance for Audi 5 Cylinder 10V Turbo Valve Shims

The Audi 5 cylinder 10V turbo engine is an iconic powerplant known for its durability, smooth power delivery, and unique sound. Among the many components that keep this engine running efficiently, valve shims play a crucial role in maintaining proper valve clearance and ensuring optimal performance. This guide will provide in-depth information about Audi 5 cylinder 10V turbo valve shims, their function, symptoms of incorrect valve clearance, maintenance procedures, and more.

What Are Valve Shims?

Valve shims are small, precisely machined discs that adjust the clearance between the camshaft lobes and the valve lifters (tappets). In overhead cam engines like Audi’s 5-cylinder turbocharged 10V engines, the correct clearance ensures smooth valve operation, optimal combustion, and reduced engine wear.

Importance of Valve Shims in Audi 5 Cylinder Engines

Maintaining proper valve clearance is essential for:

- Engine Performance: Correct valve timing ensures efficient airflow, improving power and fuel efficiency.

- Longevity: Proper valve clearance prevents premature wear of the valvetrain components.

- Noise Reduction: Incorrect valve clearance can lead to excessive noise, affecting driving comfort.

- Fuel Efficiency: Poor clearance leads to improper combustion, reducing fuel economy.

Symptoms of Incorrect Valve Clearance

Over time, valve clearances can change due to wear, requiring adjustment. Common symptoms of incorrect valve clearance include:

- Tapping or Clicking Noises: Excessive clearance causes noticeable valve train noise.

- Loss of Power: Inconsistent valve operation affects engine performance.

- Rough Idling: Irregular valve clearance may cause unstable engine idle.

- Increased Fuel Consumption: Inefficient combustion leads to higher fuel usage.

- Engine Misfires: Poor valve sealing can result in misfiring cylinders.

Maintenance and Adjustment of Valve Shims

Routine valve clearance checks and adjustments help maintain the efficiency of the Audi 5 cylinder 10V turbo engine. Inspecting and adjusting valve clearances approximately every 60,000 miles or as specified in the owner’s manual is recommended.

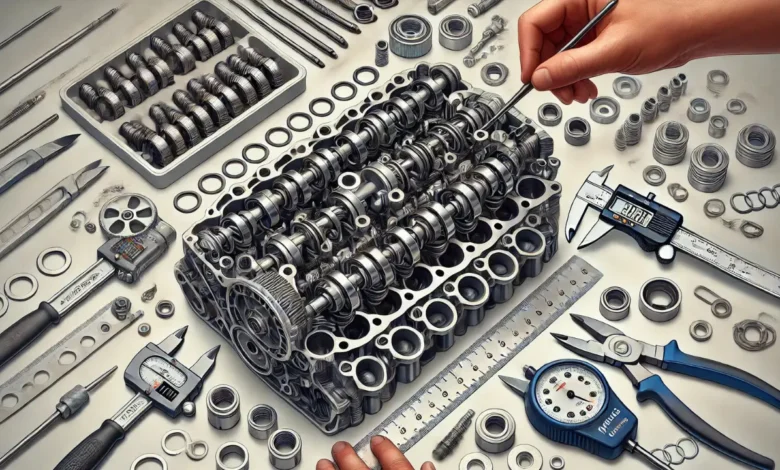

Tools Needed

To inspect and replace valve shims, you will need:

- Feeler gauges

- Valve shim tool

- Micrometer or digital caliper

- Replacement shims

- Torque wrench

Step-by-Step Valve Shim Adjustment Process

- Prepare the Engine: Ensure the engine is cold before starting the procedure.

- Remove the Valve Cover: Carefully remove the valve cover to access the camshaft and lifters.

- Measure Valve Clearance: Use feeler gauges to check the clearance between the camshaft flanges and the valve lifters.

- Determine Required Shim Thickness: Calculate the required thickness if clearance is out of specification.

- Remove Old Shims: Use a valve shim tool to extract the existing shims.

- Install New Shims: Place new shims of the correct thickness to achieve the specified clearance.

- Recheck Clearance: After installing the new shims, measure the clearance again to ensure accuracy.

- Reassemble the Engine: Secure the valve cover and reconnect components before starting the engine to check for proper operation.

Choosing the Right Valve Shims for Your Audi 5 Cylinder 10V Turbo

Valve shims come in various thicknesses, typically measured in increments of 0.05mm. When selecting shims:

- Refer to the manufacturer’s specifications for clearance values.

- Use high-quality shims from reputable suppliers to ensure durability.

- Avoid reusing old or worn shims, as they may not provide accurate clearance.

Common Mistakes to Avoid

- Skipping Regular Inspections: Neglecting valve clearance checks can lead to engine damage.

- Using Incorrect Shim Thickness: Always measure and calculate precisely to avoid incorrect adjustments.

- Not Rechecking After Installation: Always verify the clearance after replacing shims to ensure accuracy.

- Over-Tightening Components: Use the correct torque specifications to prevent damage.

Conclusion

Maintaining the valve shims in an Audi 5 cylinder 10V turbo engine is crucial for optimal performance, longevity, and efficiency. Regular inspections and timely adjustments ensure smooth engine operation, enhance power delivery and prevent costly repairs. Following proper maintenance practices and high-quality valve shims, Audi enthusiasts can keep their classic 5-cylinder turbo engines running at peak performance for years.

FAQs About Audi 5 Cylinder 10V Turbo Valve Shims

How often should I check and adjust the valve shims on my Audi 5 cylinder 10V turbo engine?

Inspecting and adjusting valve clearances approximately every 60,000 miles or as specified in your owner’s manual is recommended. Regular maintenance ensures optimal performance and prevents premature engine wear.

What are the signs of incorrect valve clearance in an Audi 5 cylinder 10V turbo engine?

Common symptoms include tapping or clicking noises from the engine, loss of power, rough idling, increased fuel consumption, and engine misfires. Addressing these symptoms promptly can prevent further damage.

Can I reuse old valve shims during the adjustment process?

Reusing old or worn shims is not advisable as they may not provide accurate clearance. Always replace them with high-quality, correctly sized shims to ensure proper valve operation and longevity.

What tools are needed to adjust valve shims on an Audi 5 cylinder 10V turbo engine?

You’ll need feeler gauges, a valve shim tool, a micrometer or digital caliper for measuring shim thickness, replacement shims, and a torque wrench for reassembly.

How does incorrect valve clearance affect fuel efficiency in Audi 5 cylinder 10V turbo engines?

Improper valve clearance can lead to inefficient combustion due to incorrect valve timing, causing increased fuel consumption and reduced overall performance. Regular adjustments help maintain optimal fuel efficiency.

You May Also Read: RC12FF Cross: A Dual-Purpose Innovation in Hydraulic and Spark Plug Technologies