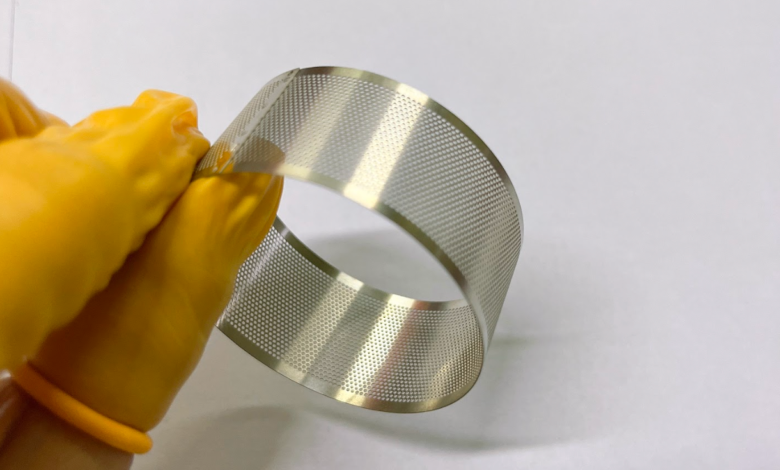

Custom Metal Mesh Filters for Industrial Equipment

In modern industrial systems, filtration is not just a supporting function—it is often critical to equipment reliability, process stability, and product quality. From fluid handling and air management to thermal control and contamination prevention, custom metal mesh filters play a vital role across a wide range of industrial equipment.

From a metal manufacturing expert’s perspective, the growing demand for precision, durability, and repeatability has pushed traditional woven wire meshes to their limits. This is where chemically etched metal mesh filters stand out as a high-performance alternative.

This article explores how custom metal mesh filters are used in industrial equipment, why chemical etching is increasingly preferred, and how TMNetch custom metal mesh filter service supports advanced filtration requirements.

What Are Custom Metal Mesh Filters?

Metal mesh filters are flat or formed metal components featuring precisely distributed openings that control the passage of liquids, gases, or particulates. Unlike off-the-shelf meshes, custom metal mesh filters are engineered to meet exact specifications, including:

- Aperture size and shape

- Open area percentage

- Material type and thickness

- Flow rate and pressure resistance

- Mechanical strength and corrosion resistance

In industrial environments, these parameters directly affect system efficiency and service life. A poorly matched filter can cause pressure drops, clogging, premature wear, or even equipment failure.

Why Metal Mesh Filters Are Essential in Industrial Equipment

Industrial equipment often operates under harsh conditions: high temperatures, corrosive media, vibration, and continuous duty cycles. Polymer or fiber-based filters may degrade quickly in these environments, while metal mesh filters offer clear advantages:

- High temperature resistance

- Long service life and reusability

- Structural stability under pressure

- Compatibility with aggressive chemicals

- Consistent filtration performance

For these reasons, metal mesh filters are widely used in industrial pumps, compressors, heat exchangers, fuel systems, hydraulic systems, and air handling units.

Limitations of Traditional Woven Wire Mesh

Woven wire mesh has been the standard filtration solution for decades, but it presents several limitations when precision and consistency are required:

- Aperture size variation due to wire deformation

- Limited design flexibility for complex patterns

- Fraying or broken wires over time

- Difficulty achieving very fine or highly uniform openings

In applications where micron-level accuracy or repeatable flow characteristics are critical, these limitations can become performance bottlenecks.

Chemical Etching: A Superior Method for Metal Mesh Filters

Chemical etching, also known as photochemical etching, produces metal mesh filters by removing material through controlled chemical reactions, rather than weaving or mechanical cutting.

From a manufacturing standpoint, this approach offers several decisive advantages:

- Uniform apertures with tight dimensional control

- Burr-free edges that reduce turbulence and particle trapping

- No mechanical stress or heat distortion

- Freedom to design complex hole shapes and patterns

- Excellent repeatability from prototype to volume production

Because the process is tool-free, design changes can be implemented quickly—making chemical etching ideal for both development and mass production of custom mesh filters.

Common Industrial Applications of Custom Metal Mesh Filters

Fluid Filtration Systems

In hydraulic, lubrication, and fuel systems, etched metal mesh filters help remove contaminants while maintaining stable flow rates. Stainless steel and nickel alloys are commonly used for their corrosion resistance and mechanical strength.

Air and Gas Filtration

Industrial air handling units, compressors, and vacuum systems rely on metal mesh filters to protect sensitive components from dust and debris, especially in high-temperature or chemically aggressive environments.

Thermal and Process Equipment

In heat exchangers and chemical processing equipment, metal mesh filters support fluid distribution, flow control, and particulate separation without degrading under heat or pressure.

Precision Industrial Sensors

Many industrial sensors incorporate etched metal mesh filters to protect internal elements while ensuring accurate signal transmission and airflow control.

Materials Commonly Used for Etched Metal Mesh Filters

Material selection is critical for filter performance and longevity. Chemical etching supports a wide range of industrial metals, including:

- Stainless steel (304, 316): corrosion resistance and structural stability

- Nickel and nickel alloys: high-temperature and chemical resistance

- Copper and brass: conductivity and specific fluid applications

- Aluminum: lightweight filtration solutions

- Titanium: extreme corrosion resistance for specialized environments

Each material responds differently to etching chemistry, so process control and experience are essential to achieving consistent results.

TMNetch Custom Metal Mesh Filter Service (Chemical Etching)

For manufacturers seeking high-precision filtration solutions, TMNetch provides custom metal mesh filter services using chemical etching tailored for industrial equipment.

TMNetch Capabilities

From a metal fabrication expert’s viewpoint, TMNetch combines process depth with production flexibility:

- Specialized in photochemical etching since 2011

- ISO 9001:2015 certified, ensuring quality and traceability

- Supports multiple industrial metals, including stainless steel, nickel, copper alloys, aluminum, titanium, molybdenum, and more

- Capable of producing highly uniform mesh patterns with precise aperture control

- Suitable for thin and medium-gauge metal sheets, depending on material and design

- Offers rapid prototyping, allowing fast validation of filtration performance

- Provides secondary services, such as plating, surface finishing, bending, and forming

Why Choose TMNetch for Custom Mesh Filters

TMNetch custom metal mesh filter service is particularly well-suited for:

- Industrial equipment requiring consistent flow and filtration accuracy

- Applications where woven mesh variability is unacceptable

- Designs with complex aperture patterns or high open-area ratios

- Customers needing quick design iterations without tooling costs

By using chemical etching, TMNetch delivers mesh filters that balance precision, durability, and scalability.

Design Considerations for Custom Metal Mesh Filters

When designing etched metal mesh filters, experienced manufacturers typically evaluate:

- Required filtration rating and particle size

- Target open area and pressure drop

- Operating temperature and chemical exposure

- Material thickness versus mechanical strength

- Cleaning and reuse requirements

Close collaboration between design engineers and the etching supplier ensures the final filter performs reliably in real-world industrial conditions.

Conclusion

Custom metal mesh filters are a critical component in industrial equipment where reliability and precision matter. While traditional woven meshes remain suitable for basic applications, chemically etched metal mesh filters provide superior control, consistency, and design freedom for advanced industrial systems.

By leveraging TMNetch custom metal mesh filter service using chemical etching, manufacturers can achieve filtration solutions that meet demanding technical requirements while maintaining efficiency from prototype to production. For industries that depend on stable performance and long service life, etched metal mesh filters are not just an option—they are often the optimal solution.