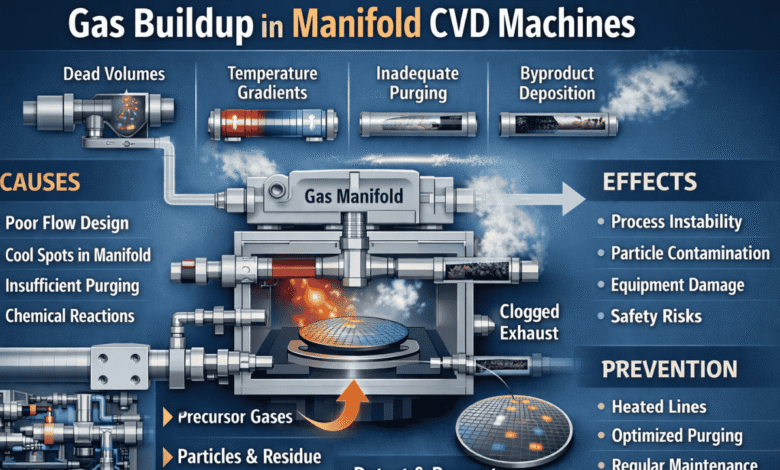

Gas Buildup in Manifold CVD Machines: Causes, Effects, and Prevention Strategies

Chemical Vapor Deposition (CVD) is a critical process used across semiconductor manufacturing, thin-film coating, optics, and advanced materials fabrication. While modern CVD systems are highly engineered for precision and repeatability, one persistent challenge remains: gas buildup in manifold CVD machines. This issue can quietly degrade process stability, reduce product quality, and increase maintenance costs if not properly understood and controlled. This article provides a comprehensive look at gas buildup in manifold CVD machines, including how it occurs, why it matters, common symptoms, root causes, and best practices for prevention and mitigation.

Understanding Gas Buildup in Manifold CVD Machines

Gas buildup in manifold CVD machines refers to the accumulation of unreacted precursor gases, reaction byproducts, condensable vapors, or solid residues inside the gas distribution system. This typically occurs in:

- Gas inlet manifolds

- Mixing chambers

- Valve blocks

- Distribution lines

- Exhaust and foreline manifolds

Over time, these accumulations can interfere with gas flow, affect film quality, and pose reliability or safety risks.

Manifolds are especially vulnerable because they often contain:

- Complex internal flow paths

- Dead volumes

- Temperature gradients

- Multiple gas injection points

If gas flow and thermal management are not carefully controlled, buildup becomes inevitable

Why Gas Buildup Occurs in CVD Manifolds

Dead Volumes and Poor Flow Geometry

Manifolds frequently contain small cavities, corners, or unused flow paths where gases stagnate. These regions allow precursor molecules or reaction byproducts to linger longer than intended, increasing the chance of:

- Chemical reactions occurring outside the chamber

- Condensation of low-vapor-pressure species

- Particle formation

Even small dead volumes can accumulate significant residue over time.

Temperature Gradients in the Manifold

One of the most common causes of gas buildup in manifold CVD machines is uneven temperature control. When portions of the gas delivery system are cooler than the process chamber:

- Vapors condense into liquids or solids

- Reaction byproducts plate out on metal surfaces

- Sticky residues form and grow layer by layer

This is especially common in:

- Metal-organic CVD (MOCVD)

- Tungsten or metal nitride deposition

- Processes using low-vapor-pressure precursors

Inadequate Purging

Improper or insufficient purge cycles allow residual gases to remain trapped in the manifold between process steps. Over time this leads to:

- Cross-contamination between chemistries

- Formation of unwanted compounds

- Progressive buildup on internal surfaces

Purge inefficiency is often caused by:

- Poor purge gas routing

- Low purge flow rates

- Short purge durations

- Inaccessible internal passages

Chemical Reactions Outside the Chamber

Ideally, reactions should only occur on the wafer surface. However, in reality:

- Some precursors react prematurely

- Gas-phase nucleation occurs

- Byproducts polymerize or solidify

These reactions can happen directly inside the manifold, especially when incompatible gases mix before reaching the chamber

Exhaust and Foreline Condensation

Gas buildup is not limited to inlet manifolds. Exhaust systems are equally vulnerable. As hot process gases cool downstream:

- Heavy byproducts condense

- Solid particulates form

- Lines become partially blocked

Over time, this can increase chamber pressure, reduce pumping efficiency, and cause erratic process behavior.

Effects of Gas Buildup in Manifold CVD Machines

Process Instability

Gas buildup alters effective flow rates and gas composition, leading to:

- Film thickness variation

- Non-uniform deposition

- Drift in process repeatability

Even minor buildup can change residence time and affect reaction kinetics.

Particle Contamination

Accumulated residue eventually flakes or breaks loose, releasing particles into the process stream. These particles cause:

- Wafer defects

- Yield loss

- Poor surface morphology

Particle-related defects are among the most costly issues in semiconductor fabrication.

Reduced Equipment Lifetime

Deposits inside manifolds:

- Corrode internal components

- Restrict flow paths

- Increase stress on valves and seals

This leads to more frequent maintenance, unexpected downtime, and higher operating costs.

Safety Risks

Some CVD chemistries involve:

- Pyrophoric gases

- Toxic byproducts

- Corrosive compounds

Gas buildup can increase the risk of:

- Uncontrolled reactions

- Pressure spikes

- Release of hazardous materials during maintenance

How to Detect Gas Buildup in Manifold CVD Machines

Early detection helps prevent serious damage. Common warning signs include:

- Gradual pressure drift during runs

- Increased pump load or slower pump-down

- Unstable gas flow readings

- Film non-uniformity or discoloration

- Frequent need for chamber cleaning

- Unexpected residue during maintenance

Advanced systems may use:

- Residual Gas Analyzers (RGA)

- Flow conductance monitoring

- Temperature sensors along gas lines

Prevention Strategies for Gas Buildup

Manifold Design Optimization

Modern CVD tools use:

- Minimized dead volumes

- Smooth internal flow paths

- Integrated purge channels

- Compact manifold layouts

Good design is the first line of defense against buildup.

Heated Gas Lines and Manifolds

Maintaining a consistent temperature prevents condensation. Best practices include:

- Heated gas delivery lines

- Heated valve blocks

- Insulated manifolds

- Controlled thermal gradients

This is especially important for metal-organic precursors.

Effective Purge Sequences

Proper purging should:

- Reach all internal cavities

- Use sufficient flow rates

- Be long enough to fully clear residual gases

- Be sequenced correctly between chemistries

In many systems, optimized purge timing alone can dramatically reduce buildup.

Regular Preventive Maintenance

Scheduled cleaning of:

- Gas manifolds

- Baffles

- Exhaust lines

- Valve assemblies

prevents long-term accumulation. Maintenance intervals should be based on process chemistry rather than fixed time schedules.

Exhaust and Foreline Management

To prevent downstream buildup:

- Heat exhaust lines when necessary

- Avoid sharp temperature drops

- Use proper exhaust materials

- Monitor pressure and flow trends

Some systems also inject heated carrier gas to keep byproducts in vapor form.

Industry Best Practices

Leading semiconductor fabs and CVD tool manufacturers typically follow these guidelines:

- Design manifolds with minimal internal volume

- Avoid mixing reactive gases before the chamber

- Maintain consistent thermal profiles

- Implement automated purge routines

- Track pressure and flow trends over time

- Perform root-cause analysis after residual events

These practices significantly reduce gas buildup in manifold CVD machines and improve tool uptime.

Future Trends in Managing Gas Buildup

Emerging technologies are improving control over gas buildup, including:

- Smart manifolds with embedded sensors

- AI-driven predictive maintenance

- Advanced coatings that resist deposition

- Modular manifold designs for easy replacement

- Improved precursor chemistry with cleaner decomposition

As CVD processes become more advanced, managing gas behavior at the manifold level will remain a critical engineering focus.

Conclusion

Gas buildup in manifold CVD machines is a complex but manageable challenge. It arises from a combination of chemical reactions, temperature gradients, poor flow design, and insufficient purging. Left unchecked, it can lead to process instability, particle contamination, equipment damage, and safety risks.

You May Also Read: Decoding the Mystery of Part Number SJ98-10C666-B: Applications, Identification, and Importance Across Industries