High Voltage Test Equipment: Ensuring Safety and Reliability

High voltage systems have become critical elements in the modern electric systems as they provide electricity to everything, including cities and industrial installations. These systems carry immense amounts of energy and, as such, can be potentially very dangerous. Failing to properly and rigorously test such systems can result in costly downtime, catastrophic accidents, and severe safety hazards. This is the relevance of high voltage test equipment.

Click here to read more about high voltage test equipment manufacturers and suppliers – DEMIKS.

This guide is meant to provide fundamental insight into high voltage test equipment. In particular, we aim to discuss its role in electrical safety and reliability, the various test equipment and their industry-specific use, and the safety regulations relevant to the industry. Furthermore, such equipment, ‘to ensure the safety and integrity of high voltage electrical installations,’, ‘professional users of such equipment’, ‘the equipment usage selection and the newest developments in high voltage testing equipment technology’ will be distinguished. Knowing the equipment enhances integrity professionals’ abilities to safeguard critical electrical assets.

For more in-depth information, you should view high voltage test equipment manufacturers – DEMIKS.

The Importance of High Voltage Testing

High voltage testing validated one of the multitude of core functions focusing on assisting in protecting the operational systems’ safety and reliability, including checking the validating components’ insulation, and systems by additional dielectric subjected under a Sch setting with extremely high voltages over the limits range of more than their normally lower set in operational parameters systems.

Role in Electrical Safety

Provisioning high voltage limits tis completely focused on high voltage the safety and protection ins of an system and checking the protection insulation gaps s is of t the above due to the blistering speeds wires f mate connect on normal operating.

Applications Across Various Industries

While the industries are numerous, paragraphs include including generation electric, all and manufacturing world with the renewable growing in reliable automotive, along with the f zone tests and high voltage brakes and coils layer all assist optic lids with the.

Electric space.

The productivity.

The result of insufficient testing

The consequences of absent or insufficient high-voltage testing can be particularly damaging. They include equipment malfunctioning, which will have catastrophic consequences, such as equipment malfunctioning causing unanticipated outages, paying high repair costs, delays, which translates to loss of revenue, and all of this combined translates to the negative public perception of a career. A lot more grave is the potential of such negligence to lead to loss of life and serious injuries.

Types of High Voltage Test Equipment

A number of specialized equipment are employed to conduct high voltage check tests. Each one has a particular purpose, enabling the technician to perform system-level assessments on the technology’s electric circuitry.

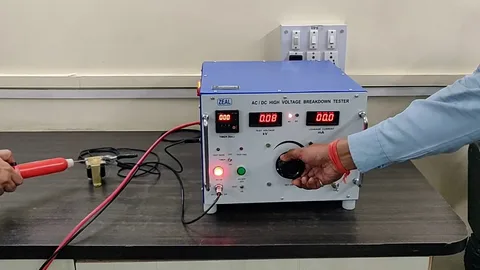

Understanding High Voltage Test Systems

High Voltage test systems, or commonly referred to as Hipot testers (High Potential testers) are invaluable to the backbone of insulation testing. They produce high voltages to test the dielectric strength of components. Systems of this nature are capable of performing AC, DC or VLF (Very Low Frequency) tests based on the system in use and the equipment undergoing examination.

High Voltage Detectors and Their Purpose

A High Voltage Detector serves as a portable line of defense to check if a circuit is live or dead. They are referred to as high voltage safety detectors and are used to confirm whether a system is electrically dead before maintenance work is put in danger of live contact. Technicians are obliged to wear and use high-voltage safety detectors as part of their primary personal safety at work.

Purpose and Usage of Instrument Transformers

Potential Transformers (PTs) and Current Transformers (CTs) are part of instrument transformers, which are utilized for measuring high voltages and currents in a safe manner. They reduce and convert high voltage and current levels to lower and safer levels, which can be readily displayed on ordinary measurement devices. This ensures safe monitoring and protection of high voltage systems as personnel as well as machinery do not have to be exposed to high energy levels.

Applications of High Voltage Test Equipment

Test devices for high voltage are beneficial for many quality assurance diagnostic processes. Such tests determine any potential failures that may develop into catastrophic malfunctions.

Testing of Cables

High voltage cables possess weak insulation that could degrade. There are three methods that can be applied to high voltage cables, using VLF, high voltage testing, or the non-destructive method to assess probable faults without damaging the cable.

Partial Discharge Testing for Diagnostics

The breakdown of partial discharge is the portion of any fluid or solid insulator that has the potential to record insulations under high voltage. Insulation systems, either solid or fluid under high voltage, could undergo PD testing devices to determine any form of discharge under the electronics. This type of discharge assumes some level of insulation disintegration. Considerable discharges are observed in transformers, switchgears and cables.

Safety Standards and Regulations

The use of high voltage equipment poses great risk, which is why there are, and must always be, stringent regulations adhered to. These procedures must be followed in order to protect staff and achieve accurate and reliable testing results.

Overview of Safety Protocols

Positioning of the test equipment and setting up the test cage, protective clothing including gloves & face shield, grounding the machine, and de-energizing the machine while attending to the maintenance of the machine is important. Equipment kept in ‘lockout/ tagout’ is de-energized and remains safe while maintenance is done.

Compliance with Industry Standards

The IEEE (Institute of Electrical and Electronics Engineers), IEC (International Electrotechnical Commission), and ASTM (American Society for Testing and Materials) all have set and regulated high voltage testing procedures and equipment regulations. These procedures must be followed in order to achieve consistent and reliable testing within the industry.

Importance of Regular Maintenance and Safety Checks

High voltage equipment must be preserved and calibrated constantly in order to ensure accurate results. It is important that operators remain safe throughout inspections, performance evaluations, and calibrations. All supervision and calibrations must be done by approved institutions and laboratories.

Choosing the Right High Voltage Testing Equipment

Making the right choice in equipment selection is necessary for efficient and safe testing. Many aspects have to be taken into account in order to be educated in the selection process.

Considerations for Equipment Selection

When choosing equipment for high voltage testing, consider the following:

Sufficient Voltage and Power Capabilities: The equipment needs to have the ability to achieve the necessary voltage levels for the testing to be done.

Test Type: Assess the testing needs and determine the capabilities required for AC, DC, or VLF testing.

Flexibility: For field operations, easily transportable and durable equipment is necessary. For the lab, other sizeable and multifunctional systems may be more appropriate.

Equipment Safety: Emergency switches, safety locks, and safety indicators are the kinds of assets to consider.

Equipment Testing Performance Assessment

Measurable performance indicators serve as the basis for evaluating performance. Going through the equipment specs provided by the manufacturer, obtaining documents of independent certifications such as UL or CE, and analyzing performance feedback gives an overview of the equipment performance.

Equipment Users Services and Maintenance

The support and equipment service provided by the manufacturer is very important. Determine the range of technical assistance, training, calibration, and repair. A comprehensive network of service and support guarantees the optimal state of the equipment as well as necessary assistance.

Recent Technological Advancements

High Voltage Testing is a continually advancing field. New technologies enhance the effectiveness, precision and safety of high voltage testing.

Improvements in Methods of Testing High Voltage.

Advancing sensors and faster computing technologies enhance the sophistication of testing models. Digital monitoring systems, for instance, help reduce equipment downtime by allowing monitoring of the equipment’s health in real-time while in use.

Use of Digital Technologies in Testing Equipment.

Today’s High Voltage Test Equipment provides full-automation capability with integrated digital controls and data loggers which enhances safety and efficiency. The equipment’s wireless connectivity comes in handy for remote quest logging and real-time operation.

Predicted Future Developments of High Voltage Test Systems.

High Voltage Test Systems will increasingly incorporate Artificial Intelligence and Machine Learning technologies. These systems will analyze high volumes of testing data and more accurately predict failures, recommend maintenance, and optimize system reliability.

Challenges in High Voltage Testing

Technological advancements still have various challenges to overcome for high voltage testing professionals.

Issues Faced by Professionals

Some challenges encountered are environmental conditions such as temperature and humidity that greatly influence test outcome, testing within narrow, complex, or high spaces, and the dangers involved in testing outdated structures.

Strategies to Overcome Testing Challenges

Addressing such challenges require deliberate and detailed pre-occupancy planning, the use of portable equipment that is environmentally protected, and well-structured safety compliance policies and procedures. Diagnostic procedures that are advanced and tested in tough environments can also yield reliable results.

The Value of Continuous Education and Training

The evolution of complex electrical systems alongside the testing devices has rendered the need of more education and training. Safety standards, advanced technologies, and testing methodologies are equally important to ensure the memorizing of such concepts for the purpose of executing the job properly and safely.

Ensuring a Safer Electrical Future

To ensure safety, efficiency, and dependability within our electrical infrastructure, high voltage test equipment is fundamental. This equipment fundamentally ascertains the dependability of the entire national power grid while protecting lives and avoiding failures as ascertains the dependability of the entire national power grid. This also holds true for basic cables. The role of high voltage testing will only continue to grow as the technology expands and our reliance on electricity becomes more prominent. These professionals show extreme confidence when dealing with high voltage systems as they choose the most effective tools, meet the highest safety standards, and allocate resources for continuous improvement. Moreover, they ensure that the electrical systems implemented in the future are reliable and safe.