How to Extend the Life of Your John Deere Cotton Picker with the Right Replacement Parts

The John Deere cotton picker is a powerhouse in modern agriculture. Known for its reliability, efficiency, and durability, this machine plays a critical role during harvest. However, like all hardworking machines, it needs care and attention, especially when it comes to replacement parts. By choosing the right components and maintaining a consistent service routine, you can significantly extend the life of your John Deere cotton picker, reduce downtime, and maximize your investment.

In this comprehensive guide, we’ll explore how proper maintenance and quality replacement parts can boost the longevity and performance of your machine.

Why Replacement Parts Matter

Every moving component in a cotton picker is subject to wear and tear. From the spindles and moisture pads to belts and drum assemblies, these parts must operate in sync to ensure optimal harvesting. When even one of them fails, the efficiency of your entire operation can suffer.

Using high-quality replacement parts:

- Reduces machine downtime

- Ensures consistent harvesting performance

- Maintains the integrity of your John Deere cotton picker

- Helps prevent collateral damage to other components

The key is not just replacing parts, but replacing them with the right ones.

Genuine vs. Aftermarket: Making the Smart Choice

You’ll encounter two main types of replacement parts: genuine John Deere parts and aftermarket parts. While aftermarket options may seem cheaper upfront, they often come with trade-offs in material quality, fit, and longevity.

Genuine John Deere Parts are engineered specifically for your cotton picker. They undergo rigorous quality checks and are backed by manufacturer warranties. These parts:

- Fit seamlessly with existing systems

- Last longer under tough field conditions

- Maintain your warranty coverage

Aftermarket Parts, on the other hand, vary in quality. While some reputable third-party manufacturers produce reliable components, others cut corners on material and design.

Recommendation: If you want to extend the life of your John Deere cotton picker, use genuine parts or high-quality aftermarket parts from vetted suppliers.

Essential Replacement Parts That Impact Longevity

Not all parts wear out at the same rate. Here’s a breakdown of the most critical components that affect the lifespan and efficiency of your cotton picker:

1. Spindles

Spindles are at the heart of the picking mechanism. Worn or damaged spindles can reduce cotton yield and increase fiber contamination. Replace them before harvest to avoid costly rework and lost crop.

2. Moisture Pads & Doffers

These components clean and release cotton from the spindles. If they’re worn or hardened, they can damage cotton or reduce cleaning efficiency. Regular inspection and seasonal replacement are essential.

3. Belts and Chains

Belts drive the picker units, while chains coordinate internal movement. Replacing them before they stretch or crack prevents failures during peak harvesting times.

4. Drum Assemblies

These large components house the spindle bars. Drum wear can throw off the machine’s balance, reducing productivity and increasing strain on other parts.

5. Hydraulic Components

Seals, hoses, and pumps must remain in top shape to support steady picking head movement. Watch for leaks and pressure drops as signs of wear.

Maintenance Best Practices

Maintaining your John Deere cotton picker isn’t just about reacting to breakdowns. Preventive care keeps your machine in peak condition for years to come.

1. Follow the Service Schedule

John Deere recommends a detailed maintenance calendar. Stick to it. Most failures occur when scheduled inspections are skipped or delayed.

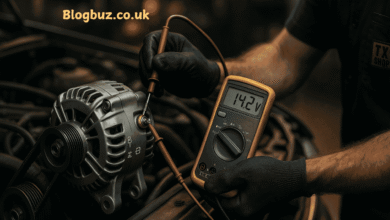

2. Use Diagnostic Tools

Modern cotton pickers come with onboard diagnostics. Use these tools to detect potential issues early and determine when parts are nearing their service limits.

3. Keep a Maintenance Log

Track every repair and replacement. This historical data helps you predict future needs and plan for part replacements before they become urgent.

4. Inspect Before and After Harvest

Thoroughly inspect the picker before and after harvest. Look for wear, corrosion, and loose fittings. This minimizes the risk of unexpected breakdowns during the picking season.

Storage Tips to Prolong Part Life

Even when not in use, your John Deere cotton picker needs proper storage to protect sensitive parts:

- Clean thoroughly to remove plant debris and sap, which can corrode metal components.

- Store indoors or under a tarp to prevent UV damage and moisture intrusion.

- Drain fuel and fluids if storing long-term or use stabilizers to prevent gumming.

- Remove batteries to avoid power drain and corrosion.

- Grease moving parts to prevent rust.

Where to Source the Right Parts

When it’s time to buy replacement parts, sourcing from a reputable dealer is key. John Deere dealerships provide:

- Access to OEM parts

- Professional installation if needed

- Expert advice based on your model and harvesting conditions

Additionally, many authorized dealers offer:

- Online catalogs

- 24-hour shipping during harvest season

- Seasonal discounts and maintenance kits

If you go the aftermarket route, do your homework. Choose suppliers with strong customer reviews, documented part specs, and clear return policies.

Custom Upgrades to Consider

Beyond basic replacements, you can also upgrade certain components to enhance performance:

- High-performance spindles made with enhanced alloys for greater durability

- Advanced doffers with improved cleaning capacity

- Moisture sensor kits for real-time harvesting analytics

- Improved lighting kits for nighttime or low-light operations

These upgrades can reduce labor costs, improve efficiency, and further extend the life of your John Deere cotton picker.

Signs It’s Time to Replace a Part

Here are a few red flags that indicate a part may be reaching the end of its lifespan:

- Unusual noises from drums or belts

- Reduced picking efficiency

- Uneven spindle rotation

- Hydraulic fluid leaks

- Visible cracks, rust, or deformation

Addressing these signs early keeps your picker in the field and out of the shop.

Final Thoughts

Your John Deere cotton picker is a long-term investment. To maximize its lifespan and performance, it’s crucial to stay proactive with maintenance and only use the right replacement parts. Whether you choose genuine OEM or premium aftermarket components, make sure every piece is designed to work harmoniously with your machine.

By understanding your picker’s most vulnerable parts, maintaining a regular service routine, and storing it properly off-season, you’ll keep your cotton picker running efficiently for years to come—and ensure every harvest is as productive as possible.

Remember: It’s not just about replacing parts. It’s about replacing them right.