In CVD Semiconductor Process Is Manifold Kept Hot: Principles, Reasons, and Engineering Considerations

Chemical Vapor Deposition (CVD) represents one of the most advanced techniques in the field of critical process technologies in modern semiconductor manufacturing. It enables the controlled formation of thin films that underpin integrated circuits, power devices, MEMS, and advanced logic and memory chips. Within a CVD system, every component—from the gas source to the reactor chamber—must be carefully engineered to ensure repeatability, uniformity, and yield. One design feature that often raises questions is why, in CVD semiconductor process is manifold kept hot. This article provides a comprehensive, in-depth explanation of this design choice. It explores the physical chemistry behind precursor delivery, the operational challenges of CVD systems, and the practical engineering benefits of maintaining a heated manifold. By the end, you will have a clear understanding of why manifold heating is not just a convenience, but a necessity in many semiconductor deposition processes.

Understanding the Role of the Manifold in a CVD System

Before addressing why the manifold is kept hot, it is important to understand what the manifold does in a CVD tool.

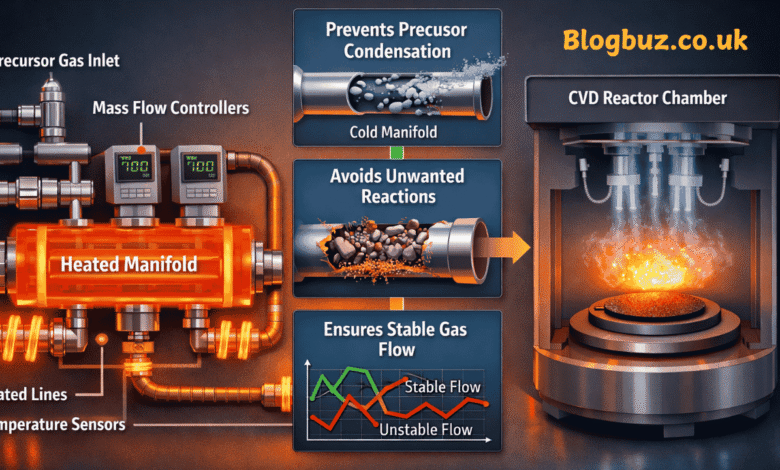

The manifold is part of the gas delivery system. It serves as a distribution hub where process gases and precursor vapors are routed, mixed (in some designs), and directed toward the reaction chamber. Typical components associated with the manifold include:

- Gas inlets from precursor sources

- Valves and mass flow controllers

- Pressure sensors and filters

- Heated delivery lines leading to the chamber or showerhead

In essence, the manifold is the “last mile” of precursor transport before the gases enter the deposition environment.

The Nature of CVD Precursors

Most CVD precursors are not simple, inert gases. Instead, they are often:

- Metal-organic compounds

- Metal halides

- Silicon-containing liquids or low-vapor-pressure solids

These materials are chosen because they decompose or react at elevated temperatures on the wafer surface, forming high-quality films. However, their physical properties introduce challenges during transport.

Many precursors:

- Have low vapor pressure at room temperature

- Condense easily on cool surfaces

- Decompose or polymerize if they stagnate

These characteristics directly explain why, in CVD semiconductor process is manifold kept hot.

Preventing Precursor Condensation

The Primary Reason for Heating the Manifold

The most fundamental reason for keeping the manifold hot is to prevent precursor condensation.

When a precursor vapor flows through metal tubing or a manifold that is cooler than its saturation temperature, it can condense into a liquid or a solid. This leads to several problems:

- Loss of delivered precursor dose

- Unstable and drifting flow rates

- Film thickness non-uniformity

- Eventual clogging of gas lines or valves

By maintaining the manifold at an elevated and controlled temperature, the precursor remains in the gas phase throughout its journey to the chamber.

In simple terms, in CVD semiconductor process is manifold kept hot to ensure that what leaves the source is exactly what reaches the wafer.

Avoiding Unwanted Chemical Reactions

Deposition Outside the Chamber Is a Major Risk

CVD reactions are designed to occur on the wafer surface, not inside the gas delivery system. However, if the manifold temperature is too low or poorly controlled, several unwanted reactions may occur:

- Premature thermal decomposition of precursors

- Reaction between multiple precursors before entering the chamber

- Formation of solid particles inside the manifold

Once deposition begins within the manifold, it forms layers of material on the internal surfaces. Over time, these layers can flake off, generating particles that contaminate wafers and reduce yield.

Heating the manifold reduces this risk by:

- Preventing condensation-driven reactions

- Maintaining steady flow conditions

- Minimizing surface residence time of reactive species

Ensuring Process Stability and Repeatability

Temperature Control Equals Flow Control

In semiconductor manufacturing, repeatability is everything. Even small variations in precursor delivery can result in measurable differences in film thickness, composition, or electrical properties.

When a manifold is not heated:

- Condensation varies with ambient conditions

- Start-up and shut-down behavior becomes unpredictable

- Flow controllers may deliver inconsistent results

By contrast, a heated manifold provides:

- Stable vapor pressure

- Predictable mass flow behavior

- Reproducible wafer-to-wafer and lot-to-lot results

This stability is one of the strongest operational reasons why, in CVD semiconductor process is manifold kept hot.

Reducing Maintenance and Tool Downtime

Reliability Is a Major Cost Driver

From a manufacturing perspective, unplanned downtime is extremely expensive. Deposits inside a cold manifold can lead to:

- Valve sticking or failure

- Pressure sensor drift

- Blocked gas paths

- Frequent cleaning cycles

A heated manifold significantly slows the buildup of unwanted material, extending maintenance intervals and improving tool uptime.

Although heating adds complexity and energy consumption, it ultimately reduces the total cost of ownership by preventing failures and contamination events.

Supporting Advanced CVD and ALD-Like Processes

As semiconductor devices scale down, deposition processes become more demanding. Many modern processes require:

- Pulsed precursor delivery

- Extremely precise dose control

- Fast switching between gases

In these regimes, even small dead volumes or cold spots in the manifold can cause memory effects or cross-contamination between pulses.

Maintaining the manifold at an elevated temperature:

- Eliminates stagnant zones

- Improves purge efficiency

- Supports sharp on/off precursor transitions

This is especially important in processes that blur the line between traditional CVD and atomic-layer-like deposition schemes.

Engineering Considerations in Manifold Heating

Not “As Hot As Possible,” But “As Controlled As Necessary”

While heating is essential, excessive temperatures can also cause problems. Engineers must carefully balance manifold temperature to:

- Stay above precursor condensation temperature

- Remain below decomposition temperature

- Avoid damaging seals, sensors, or electronics

Common design approaches include:

- Heat tracing with resistive heaters

- Insulated manifold blocks

- Closed-loop temperature controllers

- Zoning to avoid hot or cold spots

The goal is uniform, stable thermal conditions rather than maximum heat.

Differences Between Manifold Heating and Chamber Heating

It is important to distinguish manifold heating from wafer or chamber heating.

- The wafer is heated to drive surface reactions.

- The chamber walls may be hot or cool depending on the reactor design.

- The manifold is heated primarily to maintain transport stability, not to improve reaction kinetics.

Thus, in CVD semiconductor process is manifold kept hot for reasons that are fundamentally different from why the wafer itself is heated.

When a Manifold Might Not Be Heated

Not every CVD system uses a heated manifold. Situations where heating may be reduced or unnecessary include:

- Processes using only permanent gases

- Very high-flow, low-reactivity chemistries

- Simple atmospheric-pressure systems

However, as soon as low-vapor-pressure or reactive precursors are introduced, manifold heating becomes increasingly important.

Future Trends in Manifold Design

As device architectures become more complex, gas delivery systems are evolving. Trends include:

- Integrated heated valve–manifold modules

- Shorter gas paths to reduce residence time

- Advanced materials to resist deposition

- Smarter thermal control with real-time feedback

These innovations reinforce the same core principle: precise control of precursor state is essential for advanced semiconductor manufacturing.

Conclusion

So, why in CVD semiconductor process is manifold kept hot? The answer lies in a combination of physics, chemistry, and manufacturing economics. Heating the manifold prevents precursor condensation, prevents unwanted reactions, ensures stable, repeatable delivery, reduces contamination, and improves overall tool reliability.

You May Also Read: Gas Buildup in Manifold CVD Machines: Causes, Effects, and Prevention Strategies