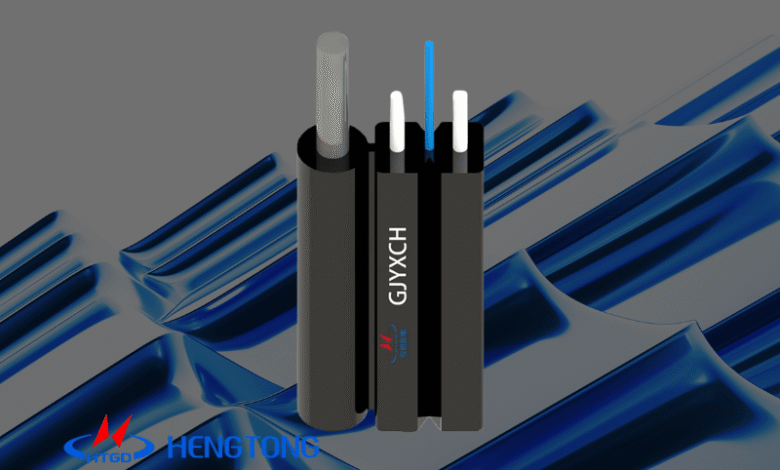

Indoor Optical Cable

Global demand for Indoor Optical Cable is rising as building fit-outs and data-center expansions accelerate. Inside facilities, backbones are migrating from low-count duplex pulls to high-count trunks (commonly 24/48/72 fibers) to reduce pathway runs, raise rack port density, and simplify moves/adds/changes. A key enabler is bend-insensitive glass: the ITU standard G.657.A2 specifies fibers appropriate for a minimum design bend radius of 7.5 mm, allowing tight routing through cabinets and raceways with lower macrobend loss; G.657.B categories further optimize bend performance for short-reach, in-building scenarios.

Several product lines aligned to G.657.B3 advertise even tighter macrobend limits—as low as 5 mm (and in some cases lower) for extremely congested paths—supporting compact ducts, shallow turns, and dense tray transitions typical of modern data halls and multi-tenant floors.

Safety codes still drive jacket selection. In North America, plenum air spaces require OFNP (or optical fiber plenum) while vertical shafts use OFNR (optical fiber riser); OFNP may substitute for OFNR where needed, but not vice-versa. Selecting the correct flame rating for each area within the same building remains a central design task during acceptance.

Across the EU and affiliated markets, the Construction Products Regulation (CPR) assigns cables to Euroclasses Aca–Fca based on reaction-to-fire performance, with telecom/ICT cables most commonly specified between B2ca (more stringent) and Fca depending on building type and national interpretations. Harmonized labeling and documentation are increasingly required to streamline cross-border procurement and inspection.

Operationally, engineering teams are tightening turn-up checklists: standardized polarity maps for trunks, OTDR baselines per route, and zone labels at main/horizontal/equipment distribution areas. Combining pre-terminated harnesses with Indoor Optical Cable trunks shortens install windows and limits field terminations, enabling faster room-by-room activations. With rack densities rising, designers are reserving slack and using bend-insensitive fibers to preserve loss budgets after inevitable pathway reworks.

What this means: As facilities densify, Indoor Optical Cable specs (fiber count, bend class, and fire rating) are being decided earlier in the design cycle. The consequence is fewer re-pulls, lower risk of macrobend-induced alarms, and a clearer compliance record for authorities and insurers.

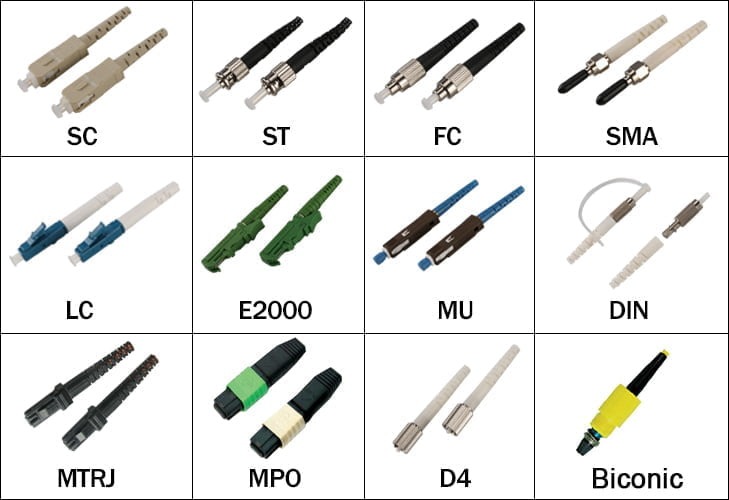

Fiber optic connector types

Procurement and interoperability planning for fiber optic connector types is being shaped by two timely developments:

1) A new international connector interface standard. In May 2025, the International Electrotechnical Commission released IEC 61754-36:2025, defining the standard mechanical interface dimensions for the Type SAC connector family. This adds a current, globally recognized reference within the IEC 61754 series and gives project teams authoritative drawings for design fit, gauge tooling, and multi-source qualification.

2) Live, multi-vendor interoperability at a major European conference. A large demonstration staged in 2025 by a leading interconnect forum showed cross-vendor operation across optical and electrical domains—including 400ZR/800ZR coherent applications and next-gen CEI-224G/448G electrical links—under realistic topologies. The demo’s scope spanned optical, electrical, energy-efficient, and management interfaces, underscoring readiness for AI-scale leaf-spine fabrics and metro/DCI builds. A companion technical brief detailed parameters such as required SNR, pre-FEC BER targets, channel loss, latency/coding-gain trade-offs, and 1-meter passive reach connectivity conditions for 448G electrical lanes.

Why it matters: Together, a fresh mechanical interface spec and public, on-floor interoperability results reduce integration risk across fiber optic connector types. They help unify ferrule/adapter geometries and refine acceptance criteria (insertion/return-loss targets, end-face quality, polarity conventions), easing mix-and-match use of trunks, cassettes, and patching hardware during large rollouts.

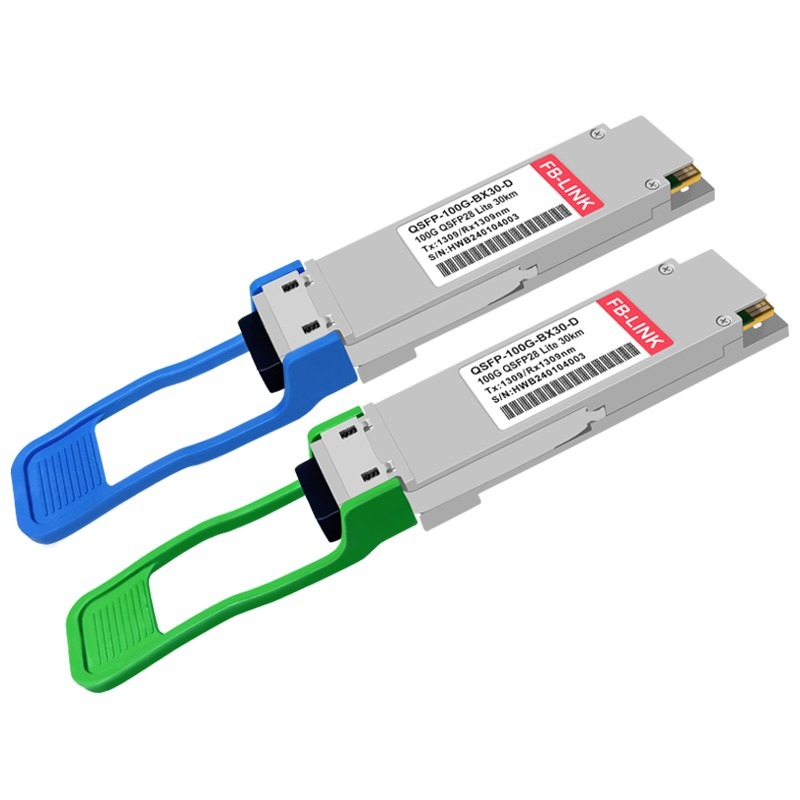

Optical transceiver

Late-2025 milestones are compressing time-to-deploy for the next generation of optical transceiver solutions:

- Clearer mechanical interfaces feeding module integration. The publication of IEC 61754-36:2025 simplifies transceiver-to-infrastructure fit for systems adopting the Type SAC family in front-panel or patch-field contexts, reducing the risk of mechanical mismatches during high-rate upgrades (800G→1.6T).

- Interoperability validated at scale. Cross-supplier demonstrations in 2025 confirmed practical co-operation of 400ZR/800ZR coherent pluggables and CEI-224G/448G electrical interfaces across multiple participants, with attention to latency, coding gain, crosstalk, skew, reflections, and connector resonance—items that directly affect module error budgets and thermal envelopes.

- A robust demand signal for coherent pluggables. Independent market tracking now projects 800ZR/ZR+ shipments to exceed 200,000 units in 2026, surpassing $1 billion in revenue as distributed sites and AI campuses require more inter-data-center bandwidth without stand-alone transport shelves. This aligns coherent pluggables with IP-integrated architectures and boosts the business case for rapid adoption.

Inside the data center, the optical transceiver roadmap is moving from volume 800G toward 1.6 T prototypes and early field pilots. Electrical interfaces at 224 Gb/s per lane are mature enough for broad interoperability events, and 448 Gb/s lanes are now being exercised in public demos with documented test conditions—signposts that system vendors will soon have the ecosystem to commercialize denser front-panel options.

Operational implications:

- Project teams are tightening loss budgets and thermal plans in parallel: higher lane rates shrink noise margins, so connector quality and short pathway lengths are prioritized alongside airflow planning around high-power faceplates.

- Selection between linear-drive and DSP-based architectures is increasingly tied to energy-per-bit and latency targets; many operators pilot both to map reach, power, and observability trade-offs before scaling.

- For spares and lifecycle costs, organizations are leaning on standardized connector drawings and multi-vendor test reports to enable second-source transceivers and cabling with minimal re-qualification.

Bottom line

- Indoor Optical Cable: Specify bend-insensitive G.657.A2 (7.5 mm) or G.657.B classes (down to 5 mm, with some offerings lower) to preserve budgets in dense routes; match OFNP/OFNR or CPR class to space type; standardize labeling and OTDR baselines for faster turn-ups.

- Fiber optic connector types: Use the new IEC 61754-36:2025 drawings where applicable and reference current interoperability results to set acceptance thresholds and mixing rules

- Optical transceiver: Expect continued 800G scaling, rapid prototyping at 1.6 T, and strong coherent demand (≥200k units in 2026, >$1B), all supported by clearer interfaces and proven multi-vendor operation.