Tech-Savvy Pet Owners’ Guide to Litter Box Odor Elimination

As tech-savvy pet owners, we’ve mastered smart homes and automated routines, yet that persistent litter box odor remains a daily challenge. Despite our technological prowess, maintaining a fresh-smelling home while caring for our feline companions can feel like an uphill battle. Today’s automated litter box systems offer promising solutions, combining precision engineering with smart technology to revolutionize pet waste management. From self-cleaning mechanisms to app-controlled monitoring, these innovations represent a significant leap forward in tackling one of pet ownership’s most persistent problems. This comprehensive guide explores how to leverage modern technology effectively for litter box odor control, helping detail-oriented pet owners create a more pleasant environment for both humans and pets. Whether you’re considering an upgrade to your current setup or seeking to optimize an existing automated system, you’ll discover practical, tech-driven solutions that make a real difference.

Understanding Litter Box Odor Science

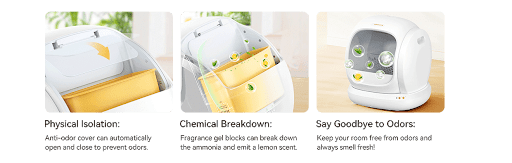

The science behind litter box odor reveals why technology alone isn’t a complete solution. When cats use their litter box, urea in their urine breaks down into ammonia through bacterial action, creating that characteristic unpleasant smell. This process accelerates in warm, humid conditions, where bacteria thrive and multiply rapidly. Modern litter technologies approach this challenge through two main methods: absorption and containment. Absorption-based solutions use advanced materials to trap ammonia molecules and neutralize their odor, while containment systems aim to seal waste away from the ambient air. However, these technological approaches face inherent limitations. Even the most sophisticated systems can’t prevent the initial chemical breakdown process, and their effectiveness depends heavily on regular maintenance and optimal environmental conditions. Understanding these scientific principles helps explain why a multi-faceted approach, combining technology with proper setup and maintenance, yields the best results in controlling litter box odors.

Automated Litter Box Solutions

Modern automated litter boxes represent a significant advancement in pet waste management through sophisticated odor control mechanisms. At their core, these systems utilize sealed waste compartments that activate immediately after your cat exits, preventing odors from permeating your living space. The self-cleaning cycles employ various technologies, from rotating drums to rake systems, each designed to separate waste from clean litter efficiently. Leading models like the Meowant Smart-Clean series incorporate dual-filtration systems, combining activated carbon filters that absorb molecular odors with HEPA filters that trap airborne particles and dander. The integration of smart technology has introduced real-time odor monitoring through sophisticated sensors that communicate with mobile apps, alerting owners when filter changes or maintenance are needed. These systems typically feature customizable cleaning schedules, with some models using AI to learn your cat’s habits and optimize cleaning cycles accordingly. The maintenance reminder systems track usage patterns and consumable levels, sending notifications when litter needs replenishing or waste compartments require emptying. This proactive approach ensures consistent odor control while minimizing manual intervention.

Key Features for Tech-Savvy Owners

Advanced automated litter boxes offer comprehensive WiFi connectivity, enabling remote monitoring and control through dedicated mobile applications. These apps provide detailed usage analytics, waste tracking, and customizable cleaning schedules. Operating at whisper-quiet levels below 40 decibels, these units ensure minimal disruption during automatic cleaning cycles. High-capacity waste compartments typically accommodate 7-10 days of single-cat use, while smart sensors monitor fill levels in real-time. Integration capabilities extend to popular smart home platforms, allowing voice commands through virtual assistants and automation routines that sync with your existing smart home ecosystem.

Strategic Litter Box Setup

Proper setup of automated litter box systems demands careful consideration of environmental factors to maximize their technological benefits. Ventilation plays a crucial role, requiring a minimum of 12 inches of clearance around the unit to ensure optimal air circulation and prevent odor concentration. When selecting a location, avoid placing the unit on carpeted surfaces, as they can trap odors and complicate maintenance; instead, opt for sealed hardwood, tile, or specialized mat surfaces that facilitate easy cleaning and protect against potential leaks. Keep the unit at least 10 feet away from high-humidity areas like bathrooms and kitchens, as excess moisture can interfere with sensor functionality and accelerate bacterial growth. For households with multiple cats, establish distinct zones with at least 15 feet between units to prevent territorial stress and ensure consistent performance of motion sensors. Position units where they’re easily accessible for routine maintenance but away from high-traffic areas that might disturb cats during use. Consider creating a dedicated maintenance schedule that aligns with the unit’s automated cleaning cycles, ensuring uninterrupted operation and optimal odor control.

Placement Optimization Guide

When mapping electrical circuits, ensure dedicated power sources for each unit to prevent overload and maintain consistent operation. Implement strategic airflow management by positioning units perpendicular to existing ventilation paths, maximizing natural air circulation. Minimize direct sunlight exposure to prevent sensor interference and maintain consistent temperature conditions. Install acoustic dampening materials on nearby walls or use sound-absorbing dividers to reduce operational noise reflection, ensuring a quiet environment that won’t discourage cat usage.

Power Management Essentials

Effective power management is crucial for maintaining consistent litter box operation and odor control. When setting up automated units, consider power cord specifications carefully – standard models typically include 6-foot cords, while premium versions offer extended 10-foot or 15-foot options for flexible placement. Never daisy-chain extension cords, as this can create fire hazards and voltage fluctuations that may affect sensor accuracy. Instead, use a single UL-listed surge protector rated for continuous operation. For uninterrupted performance during power outages, install a dedicated uninterruptible power supply (UPS) system that provides at least 30 minutes of backup power, allowing sufficient time for waste containment cycles to complete. Monitor energy consumption through smart plugs or built-in power meters, which typically show automated units consuming between 1.5-3.5 kWh monthly. Position outlets strategically at cat-height level or above to prevent cord strain and maintain proper airflow, using cord management systems to secure excess length and prevent tripping hazards while ensuring easy access for maintenance.

Step-by-Step Odor Elimination Protocol

Implementing an effective odor control system requires a systematic approach across five distinct phases. Phase 1 begins with a pre-installation diagnostic, where you’ll measure baseline odor levels using digital air quality monitors and document existing ventilation patterns. During this phase, map potential electromagnetic interference sources that could affect sensors and establish benchmark readings. In Phase 2, sensor calibration becomes critical – adjust motion detection sensitivity settings between 3-5 feet range and fine-tune odor threshold triggers based on your specific environment. Phase 3 focuses on programming automated schedules, requiring you to input cat activity patterns tracked over 72 hours to optimize cleaning cycles. Configure push notifications for waste compartment status and set maintenance alerts at 80% capacity. Phase 4 involves analyzing performance metrics through your unit’s companion app, examining cleaning cycle efficiency rates and monitoring filter saturation levels. Review usage heat maps to identify peak activity periods and adjust scheduling accordingly. Finally, Phase 5 establishes remote troubleshooting protocols – create response workflows for common alerts, set up automated diagnostic reports, and configure backup cleaning cycles for system interruptions. Document sensor recalibration procedures and maintain a digital log of system optimizations for continuous improvement.

Smart Technology for Better Pet Care

The intersection of technology and pet care has revolutionized how we approach litter box odor control, transforming a daily challenge into a manageable, automated process. By understanding the science behind odor formation and leveraging advanced automated solutions, tech-savvy pet owners can create an environment that’s consistently fresh and comfortable. The key to success lies in precise setup, strategic placement, and diligent power management—all supported by smart technology that monitors, adjusts, and maintains optimal conditions. As we look to the future, innovations in AI-driven cleaning cycles, enhanced sensor technology, and even more sophisticated odor neutralization methods promise to further streamline the pet care experience. Take the next step in optimizing your automated litter box system by implementing these technical protocols and maintenance strategies. With the right combination of technology, setup precision, and systematic maintenance, you can achieve the fresh-smelling home environment you desire while providing the best care for your feline companions.