The Precision Revolution: How CNC Technology Is Redefining Sports Car Performance

Every sports car enthusiast knows that feeling—the moment when your vehicle transforms from merely fast to absolutely exhilarating. While engine modifications often steal the spotlight, there’s a quiet revolution happening in garages and professional shops worldwide. CNC machining technology is fundamentally changing how we approach sports car enhancement, delivering precision-engineered components that were once impossible to achieve through traditional manufacturing methods.

The marriage between computer-controlled precision and automotive passion has created opportunities for performance gains that extend far beyond what off-the-shelf parts can deliver. From suspension components to aerodynamic elements, CNC-machined sports car parts are setting new standards for quality, fitment, and performance optimization.

This technological shift represents more than just better manufacturing—it’s enabling a new era of customization where every component can be tailored to specific performance goals, driving styles, and aesthetic preferences.

Understanding CNC Machining in Automotive Applications

Computer Numerical Control (CNC) machining operates on a simple yet powerful principle: precise computer-controlled cutting tools shape raw materials into exact specifications. Unlike traditional manufacturing methods that rely on human operators and mechanical templates, CNC machines execute digital designs with repeatability that measures in thousandths of an inch.

For sports car applications, this precision translates into components that fit perfectly every time. Whether creating custom intake manifolds, suspension brackets, or decorative trim pieces, CNC machining eliminates the tolerances and inconsistencies that plague mass-produced parts.

The process begins with computer-aided design (CAD) software, where engineers and enthusiasts can create detailed 3D models of desired components. These digital blueprints then control sophisticated cutting tools that carve, mill, and shape materials ranging from aluminum and titanium to exotic composites.

What makes CNC particularly valuable for automotive applications is its ability to work with a wide variety of materials while maintaining consistent quality across production runs. A small shop can produce ten identical performance parts with the same precision as a major manufacturer, democratizing access to high-quality components.

The Performance Advantage of Precision Manufacturing

Traditional manufacturing methods often require compromises. Cast parts may have internal voids or inconsistent wall thickness. Stamped components might feature stress concentrations from forming processes. Welded assemblies can introduce heat distortion that affects final dimensions.

CNC machining eliminates many of these concerns by starting with solid material blocks and removing only what’s necessary. This subtractive process ensures consistent material properties throughout each component while allowing for complex geometries that would be impossible with other manufacturing methods.

Sports car applications particularly benefit from this precision because performance modifications often operate at the edges of mechanical limits. A suspension component that’s even slightly out of specification can introduce handling inconsistencies. An intake manifold with a poor surface finish can disrupt airflow patterns that took hours of computational fluid dynamics to optimize.

The dimensional accuracy achieved through CNC machining means components fit together exactly as designed. This precision extends component life by eliminating stress concentrations from poor fitment while ensuring that performance gains match theoretical predictions. Brightstone Engineering exemplifies this standard of engineering excellence, producing components that combine reliability with measurable performance improvements.

Sports Car Wheel Spacers: A Case Study in Precision

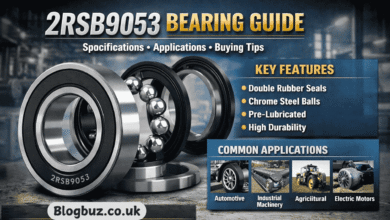

Sports car wheel spacers perfectly demonstrate how CNC technology elevates component quality and performance. These seemingly simple components play crucial roles in vehicle dynamics, affecting everything from track width and handling balance to wheel bearing loads and suspension geometry.

Traditional wheel spacers often suffer from inconsistent thickness, poor hub-centric fits, and surface imperfections that can cause vibration or premature wear. CNC-machined alternatives eliminate these issues through precise manufacturing processes that ensure perfect circular geometry, consistent thickness across the entire surface, and smooth finishes that prevent corrosion and facilitate proper installation.

The precision of CNC manufacturing allows sports car wheel spacers to maintain exact specifications that preserve vehicle safety systems. Anti-lock braking systems, traction control, and stability management all rely on precise wheel positioning and rotation characteristics. CNC-machined spacers ensure these systems continue operating as designed while delivering the aesthetic and performance benefits enthusiasts seek.

Hub-centric designs become particularly important as wheel spacer thickness increases. CNC machining can create perfectly matched hub bores that center wheels exactly on vehicle hubs, eliminating the wheel bearing stress and vibration issues associated with lug-centric designs. This precision prevents premature component wear while maintaining smooth operation at highway speeds.

Surface treatments available through CNC manufacturing also enhance longevity. Anodized aluminum surfaces resist corrosion while providing attractive finishes that complement wheel and brake system aesthetics. Precision mounting hole locations ensure even clamping loads that prevent distortion during installation.

Material Innovation Meets Manufacturing Precision

CNC technology opens doors to exotic materials that were previously impractical for sports car applications. Titanium components offer exceptional strength-to-weight ratios but require precise machining to achieve proper surface finishes and dimensional accuracy. Traditional manufacturing methods struggle with titanium’s work-hardening characteristics and tool wear issues.

CNC machines equipped with appropriate tooling and cutting strategies can successfully machine titanium into complex sports car components. Exhaust system elements, suspension hardware, and engine bay dress-up parts benefit from titanium’s corrosion resistance and weight savings while maintaining the precision fit required for proper function.

Carbon fiber machining represents another area where CNC technology excels. While carbon fiber is typically associated with molded components, CNC machining can create precise mounting points, complex contours, and integration features that would be difficult or impossible to achieve during the molding process.

Brightstone Engineering applies these advanced CNC capabilities across titanium, carbon fiber, and aluminum alloys, delivering sports car parts that combine strength, lightness, and exacting dimensional accuracy. Modern aluminum alloys can be precipitation hardened after machining to achieve strength levels approaching steel while maintaining significant weight advantages.

The Customization Revolution

Perhaps the most exciting aspect of CNC technology for sports car enthusiasts is the ability to create truly custom components. Unlike mass-produced parts that must appeal to broad market segments, CNC-machined components can be optimized for specific vehicles, driving styles, and performance goals.

Track-focused builds benefit from components optimized for aerodynamic efficiency and weight reduction. Street-driven sports cars might prioritize durability and corrosion resistance. Show vehicles can incorporate intricate aesthetic details that would be cost-prohibitive through traditional manufacturing methods.

This customization extends to fitment as well. Enthusiasts with modified vehicles often struggle to find parts that work with their specific combination of upgrades. CNC machining enables the creation of components designed specifically for unique builds, ensuring proper fit and function regardless of modification complexity.

Small-batch production runs become economically viable through CNC technology. Enthusiast communities can collaborate to justify the production of specialized components that serve niche applications. This collaborative approach has led to an explosion of boutique manufacturers offering highly specialized parts for specific vehicle platforms.

Quality Control and Consistency

CNC machining provides built-in quality control advantages that benefit sports car applications. Computer-controlled processes eliminate human error while providing real-time monitoring of cutting conditions and tool wear. Dimensional inspection can be automated to ensure every component meets specifications before leaving the machine.

This consistency proves particularly valuable for performance applications where component variations can affect vehicle balance and handling characteristics. Suspension components that vary in weight or dimensions can introduce left-to-right differences that compromise vehicle dynamics.

Traceability becomes another advantage of CNC manufacturing. Digital records track material lots, cutting parameters, and inspection results for every component. This documentation provides valuable feedback for continuous improvement while supporting warranty claims and quality investigations.

Looking Forward: The Future of Precision Performance

The intersection of CNC technology and sports car performance continues evolving as manufacturing capabilities advance and material science progresses. Additive manufacturing integration allows for hybrid components that combine the precision of CNC machining with the geometric freedom of 3D printing.

Artificial intelligence and machine learning are beginning to optimize cutting parameters and tool paths automatically, reducing manufacturing time while improving surface finish quality. These advances make high-precision components more accessible to smaller manufacturers and individual enthusiasts.

Advanced materials continue expanding possibilities for CNC-machined sports car components. Ceramic matrix composites, advanced titanium alloys, and hybrid materials offer performance characteristics that weren’t available just a few years ago.

Precision as the New Performance Standard

Sports car wheel spacers have become an essential upgrade for drivers who want to blend precision engineering with noticeable performance gains. By widening the vehicle’s stance and ensuring proper wheel-to-hub alignment, they improve handling, cornering stability, and road grip while also enhancing the aggressive aesthetics that sports car owners demand. The precision revolution in sports car performance represents a fundamental shift toward optimization over compromise. CNC-machined sports car parts deliver the exact specifications needed for maximum performance while providing customization options that reflect individual preferences and requirements.

Whether the goal is enhancing aerodynamics, reducing weight, improving durability, or achieving a bold visual statement, CNC technology provides the accuracy required to transform concepts into reality. Sports car wheel spacers and other precision components show how manufacturing excellence directly translates into both performance gains and elevated driving experiences.

Companies like Brightstone Engineering are at the forefront of this movement, turning advanced CNC processes into high-performance components that embody both technical precision and creative customization. The future belongs to enthusiasts who recognize that true performance comes from the accumulation of meticulously executed details. Every perfectly machined component contributes to a whole that exceeds the sum of its parts, resulting in sports cars that perform exactly as envisioned by their creators.