Why Leading QA Laboratories Rely on UTMs for Tensile Testing

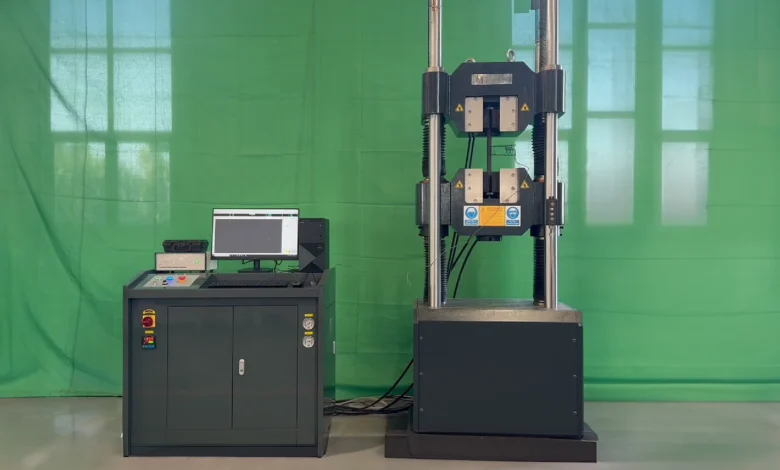

In modern quality assurance laboratories, tensile testing remains one of the most reliable ways to evaluate the strength and durability of materials. Whether the subject is a steel component for construction, a polymer used in packaging, or a textile destined for automotive interiors, the tensile test offers data that speaks directly to product performance in real conditions. The instrument at the center of this process is the universal testing machines for tensile tests.

What sets UTMs apart is their ability to act as a single platform for multiple forms of mechanical testing. Instead of relying on specialized machines for each individual method, laboratories can run tensile, compression, bending, shear, and even cyclic loading tests on the same frame with the right configuration. This flexibility allows labs to meet a wide variety of client requirements without building an entire hall of separate equipment. For organizations under constant pressure to deliver consistent, standard-compliant results, the UTM has become less an optional tool and more a fundamental part of the testing workflow.

Core Features QA Labs Look For in UTMs

The appeal of UTMs to QA laboratories begins with their versatility. In a single system, laboratories can perform not only tensile tests but also compression, flexural, and peel strength evaluations. This means that one instrument can cover the majority of mechanical assessments required across industries ranging from aerospace to consumer goods. Instead of managing multiple machines with different operating principles, engineers can simply switch grips or fixtures and adjust parameters within the same testing environment.

Material compatibility is another reason UTMs dominate in tensile testing. A well-equipped UTM can test metals, plastics, composites, elastomers, textiles, and even delicate films or fibers. Laboratories serving diverse industries benefit from this capability, as it allows them to adapt quickly to new client needs without investing in additional machines. For example, a lab conducting tensile tests on aluminum sheets for automotive parts might use the same UTM to evaluate the elongation properties of plastic tubing or the flexibility of rubber seals.

Precision and control are central to the value proposition. Modern UTMs are built with high-accuracy load cells and extensometers that measure deformation down to microns. This ensures that test results are not only compliant with ASTM and ISO standards but also repeatable across multiple batches. For quality managers, repeatability is crucial: it means data can withstand audits, client reviews, and regulatory inspections without question.

Finally, the modular design of UTMs provides scalability. A laboratory can start with a base system configured for tensile testing and expand later with accessories for high-temperature chambers, fatigue testing modules, or advanced grips. This growth potential reduces long-term costs while keeping facilities aligned with future demands. For QA teams, it transforms the UTM from a simple tensile tester into a central hub for material evaluation.

The Role of Standards, Precision, and Data Integrity

For QA laboratories, the value of tensile testing depends on standards. Modern universal testing machines support ASTM, ISO, and DIN methods, which makes results comparable across facilities and projects. When a test protocol is recognized everywhere, approvals move faster and disputes about methodology are avoided.

Accuracy comes from calibrated load cells and reliable strain measurement. In tensile testing, even a small error in force or elongation can change the conclusion about whether a material is fit for use. Properly calibrated sensors and well-chosen extensometers reduce variation and cut the need for retesting.

The digital side is just as important. Software records full stress–strain curves, collects metadata, creates reports, and exports data into LIMS. This traceability allows a result to be reviewed a year later, showing who ran the test, what grips were used, and what loading speed was applied. For industries that face audits and certification, this transparency is not a luxury but a requirement.

Why Reliable UTMs from Trusted Equipment Suppliers Matter

Machines that look similar can perform very differently over time. For leading laboratories, choosing a supplier means choosing long-term stability. Reliable UTMs from trusted equipment suppliers provide a clear chain of support: factory calibration, scheduled service, access to spare parts, and software updates. Day to day, this translates into fewer breakdowns and fewer unstable series of results.

Support begins with installation and training. When operators receive clear guidance, the lab does not depend on a single expert, and staff changes do not disrupt output. Consumables and fixtures matter as well: grips, inserts for different thicknesses, cables for sensors, and calibration weights. If these are available without long delays, the testing schedule runs smoothly.

Calibration closes the loop. Regular checks, aligned with both internal policies and client requirements, bring the machine back into its target accuracy. Reports keep a record of when the procedure was done, by whom, with which standards, and where the certificates are stored. This discipline strengthens confidence in the data and answers auditors’ questions before they are even raised.

What This Means for QA Laboratories Moving Forward

The adoption of universal testing machines has changed how quality teams approach tensile testing. What once required multiple systems can now be handled within a single platform, bringing efficiency to both large facilities and smaller labs with limited resources. By relying on one environment for tensile and related tests, teams reduce complexity, lower training demands, and free up space for other essential processes.

The long-term impact is greater than convenience. Universal testing machines give QA managers confidence that the data they present to clients and regulators is built on consistent, traceable methods. This confidence supports faster approvals, fewer disputes, and smoother relationships with both suppliers and customers.

Why UTMs Remain Central to the Future of Tensile Testing

Universal testing machines have become more than a tool for routine tensile checks. They represent an integrated approach to quality assurance, combining precision, compliance, and flexibility in one system. For leading laboratories, the choice to rely on UTMs is not about following a trend but about aligning with practices that secure reliable results and sustained credibility.

Looking ahead, advances in automation, digital reporting, and software integration will continue to expand what UTMs can do. For QA teams, the decision to invest in and maintain reliable systems ensures they are ready for stricter standards, larger workloads, and the growing demand for transparency. Universal testing machines are set to remain at the core of tensile testing, providing the foundation that modern quality assurance depends on.