Why Older Used Harley-Davidson Still Out-Torque the Newer Ones?

Every Harley-Davidson rider knows that torque is a feeling. It’s the raw mechanical heartbeat that makes the bike surge forward with unshakable authority.

Yet, in recent years, many seasoned riders and mechanics have noticed something intriguing: older Harleys often out-torque newer ones in real-world riding. As someone who has tuned and tested Harleys across generations, I can tell you that the explanation lies deep inside the crankcase, not the catalog.

And if you’re scanning listings for a used Harley-Davidson for sale, understanding this difference will change the way you evaluate a bike forever.

1. The Secret Lives of Long Strokes

Harley’s older engines, particularly the Evolution and early Twin Cam series, were built around a long-stroke design. This means the piston travels a longer distance per rotation, creating higher leverage on the crankshaft.

The result? Tremendous low-end torque even at modest RPMs.

In contrast, many newer Harleys have slightly shortened strokes to meet emissions and efficiency targets. While that improves throttle response and revving speed, it subtly reduces the mechanical advantage that creates that deep, rolling torque Harley riders cherish.

Older engines may rev slower, but they pull harder, and in practical street riding, that’s what you can actually feel.

2. The Flywheel Factor, Where Weight Works for You

Modern engines often use lighter rotating assemblies to improve responsiveness and fuel economy. But older Harleys carried heavier flywheels, which acted as torque reservoirs. When you twist the throttle, that stored rotational energy releases as a steady, linear pull rather than a spiky surge.

This is one reason a used Harley-Davidson for sale with a few decades behind it can still muscle through inclines or carry a passenger with confidence. The engine doesn’t fight the load. It actually welcomes it. That inertia is smooth, predictable, and distinctly Harley.

3. The Torque Timing Triangle: Cam, Compression, and Carburetion

Torque doesn’t live in one part. It’s a product of harmony between cam timing, compression ratio, and fueling. Earlier Harley engines, like the Twin Cam 88 and Evolution, were tuned with generous overlap and conservative ignition maps, giving them broad torque curves that deliver power from the bottom up.

Newer models, while technologically advanced, rely on strict air-fuel ratios to satisfy emissions regulations. They often run leaner, which translates to lower combustion pressure at low RPMs, the very foundation of torque.

In plain words, the old mechanical cams breathed better. They weren’t tamed by regulation; they were tuned for the road.

4. Back Pressure and the Lost Sound of Torque

Harley riders love custom exhausts, but many modern slip-ons and aftermarket pipes are designed more for volume than velocity. Older systems maintained proper back pressure, helping scavenge exhaust gases efficiently, which is a key to low-end torque.

If you come across any used Harley-Davidson with its original or well-balanced exhaust system, that’s a hidden gem. Those pipes were tuned not just for sound, but for torque preservation.

5. Mechanical Honesty Over Electronics

Torque is a tactile conversation between metal parts. Older Harleys, free from excessive electronics and ride-by-wire systems, let you feel that conversation. When you roll the throttle on a carbureted Twin Cam, torque doesn’t wait for a sensor or ECU. It responds instantly through direct cable and combustion.

That immediacy gives older bikes their “alive” feeling- a visceral, mechanical connection that even modern tuning can’t replicate.

6. Why Used Harleys Still Rule the Road

Many riders exploring a used Harley-Davidson discover something special during a test ride: torque that feels natural, predictable, and deeply satisfying. That’s because torque in older Harleys is forged by metal, mass, and movement.

Their design philosophy wasn’t built around EPA numbers or ride modes. It was about delivering authentic mechanical muscle that could handle long tours, heavy loads, and years of wear without losing character.

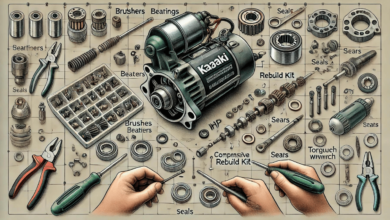

How To Evaluate Torque Health in a Used Harley

When inspecting an older Harley for its torque potential, pay attention to:

- Compression uniformity: Strong, even compression readings indicate tight seals and healthy combustion.

- Flywheel runout: Excessive runout can sap torque delivery.

- Carb tuning or EFI mapping: Look for rich midrange fuel delivery, and that’s where torque lives.

- Clutch grab point: Late or slipping engagement dilutes torque transfer.

Older Harleys were built with torque as the soul, not a spec. Every crank rotation, piston thrust, and exhaust note was tuned to translate combustion into feel. That’s why even today, a used Harley-Davidson is a living testament to a time when engines spoke through torque, not data.