Winkelbohrspindel: Angled Drilling Spindles, Applications, Types, and Benefits

The winkelbohrspindel is increasingly searched in industrial, mechanical, and CNC machining contexts. As modern manufacturing continues to evolve toward higher precision and more complex geometries, specialized tools like the winkelbohrspindel play a critical role. This comprehensive guide explains what a winkelbohrspindel is, how it works, where it is used, its main types, advantages, limitations, and why it has become an essential component in advanced machining environments.

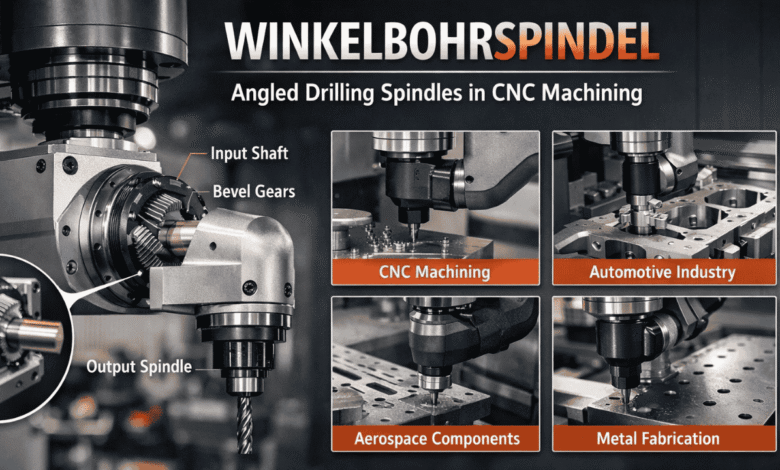

What Is a Winkelbohrspindel?

A Winkelbohrspindel is a mechanical drilling spindle designed to transmit rotational power at an angle, most commonly 90 degrees, allowing drilling, milling, tapping, or machining operations to be performed in areas that are inaccessible with a standard straight spindle. Winkelbohrspindel comes from the German language:

- Winkel means angle

- Bohr means drill

- Spindel means spindle

Combined, the term translates to angled drilling spindle or angle drilling head. These spindles are typically mounted on CNC machines, machining centers, or production equipment to enable side drilling or cross-machining without repositioning the workpiece.l Works

The working principle of a winkelbohrspindel is based on mechanical power transmission through gears. When rotational energy is supplied from the machine’s main spindle or motor, the winkelbohrspindel redirects that motion at a fixed or adjustable angle.

Key Working Steps:

- The input shaft connects to the machine spindle.

- Internal bevel or spiral gears transfer rotational energy.

- The motion is redirected—usually at 90 degrees.

- The output spindle drives the cutting tool (drill, tap, mill).

This design allows precise machining on side faces, inner corners, or complex surfaces that cannot be reached directly.

Main Components of a Winkelbohrspindel

A high-quality winkelbohrspindel consists of several precision-engineered components:

- Input Shaft – Receives power from the machine

- Gear System – Bevel or hypoid gears that redirect motion

- Output Spindle – Holds and rotates the cutting tool. Reduce vibration and ensure accuracy

- Housing – Protects internal parts and ensures rigidity. Common systems include ER collets, HSK, BT, or ISO tapers.

Each component is designed to withstand high rotational speeds, torque loads, and continuous industrial use.

Applications of Winkelbohrspindel

The winkelbohrspindel is used across many industries where angled or side machining is required.

CNC Machining Centers

In CNC environments, a wIn CNC environments, a Winkelbohrspindel enables:apping

- Multi-face machining without reclamping

This significantly reduces setup time and improves production efficiency.

Automotive Industry

Automotive manufacturing relies heavily on winkelbohrspindeln for:

- Engine block drilling

- Transmission housing machining

- Complex cast components with internal channels

Aerospace Industry

In aerospace production, whIn aerospace production, where precision is critical, Winkelbohrspindeln are used to machine:nents

- Lightweight alloys

- Parts with strict tolerance requirements

Metal Fabrication

Metal workshops use winkelbohrspindels for:

- Machining welded assemblies

- Working on complex steel structures

- Side drilling in thick plates

Woodworking and Furniture Manufacturing

In woodworking, winkelbohrspindels allow:

- Angled joints

- Hidden fastener holes

- Decorative machining operations

Maintenance and Repair Work

In industrial maintenance, a winkelbohrspindel is useful for accessing confined or obstructed areas in large machinery.

Types of Winkelbohrspindel

There are several types of winkelbohrspindeln, each designed for specific applications.

Fixed-Angle Winkelbohrspindel

- Usually set at 90 degrees

- Usually set at 90 degrees.

- Ideal for repetitive, high-volume production

Adjustable-Angle Winkelbohrspindel

- Allows multiple angle settings

- More flexible for custom machining

- Common in tool rooms and prototyping

High-Speed Winkelbohrspindel

- Designed for small-diameter tools

- Operates at very high RPM

- Ideal for aluminum, plastics, and fine machining

High-Torque Winkelbohrspindel

- Built for heavy-duty cutting

- Suitable for steel, titanium, and cast iron

- Used in demanding industrial environments

Compact or Mini Winkelbohrspindel

- Small size for tight spaces

- Used in electronics and precision engineering

- Maintains accuracy despite reduced dimensions

Advantages of Using a Winkelbohrspindel

The popularity of the winkelbohrspindel is driven by its many advantages.

Improved Accessibility

A winkelbohrspindel allows machining in locations that would otherwise be unreachable with standard tools.

Reduced Setup Time

By eliminating the need to reposition or reclamp the workpiece, production time is significantly reduced.

Increased Productivity

Multiple machining operations can be conducted in a single setup, increasing throughput.

High Precision and Repeatability

Modern winkelbohrspindels are engineered for tight tolerances and consistent results.

Versatility

They can be used for drilling, tapping, milling, and countersinking across various materials.

Cost Efficiency

Although the initial cost may be higher, the reduction in labor, setup time, and errors leads to long-term savings.

Limitations and Considerations

While a winkelbohrspindel is highly useful, there are some considerations to keep in mind.

- Speed and torque limitations due to gear transmission

- Increased machine envelope, which may require collision checks

- Higher upfront cost compared to simple attachments

- Maintenance requirements, including lubrication and gear inspection

Proper planning and correct selection ensure these limitations do not impact productivity.

Technical Specifications to Consider

When choosing a winkelbohrspindel, important specifications include:

- Maximum RPM

- Torque capacity

- Gear ratio

- Tool holding system

- Mounting interface compatibility

- Cooling and lubrication options

- Weight and dimensions

Matching these parameters to the machining task ensures optimal performance.

Winkelbohrspindel in Modern Manufacturing

As manufacturing trends move toward automation, smart factories, and complex part geometries, the role of the winkelbohrspindel continues to expand. These spindles are increasingly integrated into:

- Automated CNC production lines

- Robotic machining systems

- Multi-axis machining centers

- High-precision industrial workflows

Their ability to improve flexibility without sacrificing accuracy makes them a valuable asset in Industry 4.0 environments.

Maintenance and Best Practices

To ensure long service life and consistent accuracy, proper maintenance is essential:

- Regular lubrication of gears and bearings

- Monitoring vibration and noise

- Using recommended cutting speeds and feeds

- Preventing overload conditions

- Performing periodic inspections

Following manufacturer guidelines greatly extends operational lifespan.

Conclusion

The winkelbohrspindel is an indispensable tool in modern machining and manufacturing. Enabling angled drilling and machining operations allows manufacturers to work more efficiently, accurately, and flexibly. From CNC machining centers and automotive production to aerospace engineering and woodworking, the winkelbohrspindel plays a vital role in achieving complex designs without unnecessary setup changes.

You May Also Read: Repmold: The Future of Smart Mold Manufacturing and Rapid Production