T8461 Automation Spare Parts: Your Sourcing Solution

In modern industrial facilities, automation spare parts serve as the lifeline that keeps production lines running smoothly. When critical components fail, operations grind to a halt, costing companies thousands of dollars per hour in lost productivity. For maintenance teams and industrial technicians, sourcing reliable replacement parts quickly becomes a make-or-break challenge, especially when dealing with specialized equipment like ICS Triplex control systems.

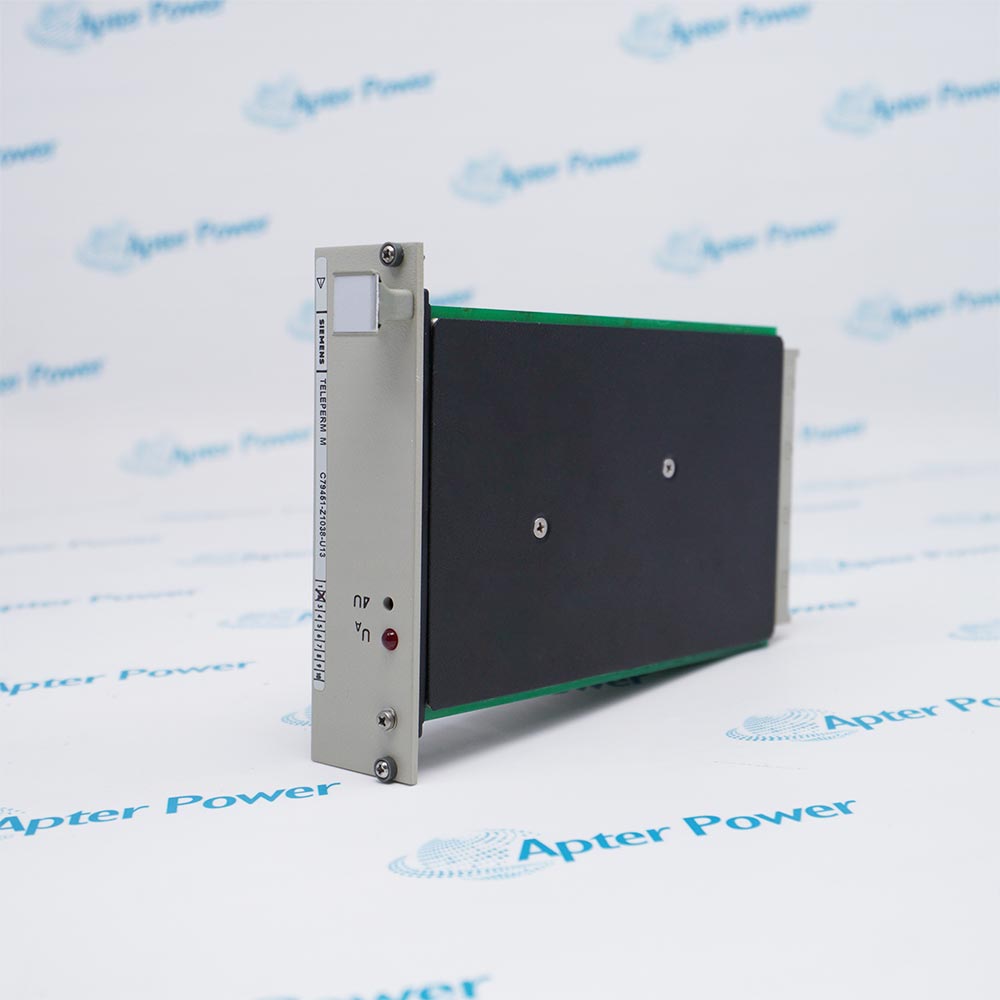

Finding authentic OEM components presents numerous obstacles—from verifying part authenticity to navigating long lead times and dealing with discontinued legacy parts. The T8461 automation module represents a prime example of these sourcing challenges, as technicians struggle to locate verified suppliers who can deliver quality components when needed most. This article provides practical guidance for overcoming common procurement hurdles, ensuring you have access to genuine automation spare parts that maintain system integrity. Whether you’re managing emergency repairs or planning preventive maintenance, understanding effective sourcing strategies will help minimize downtime and protect your investment in industrial automation infrastructure.

The Importance of Quality Automation Spare Parts

Control system drives form the nervous system of modern industrial operations, translating digital commands into precise mechanical actions that govern everything from assembly line speeds to temperature regulation in chemical processing. When these components function optimally, production flows seamlessly with minimal intervention. However, the moment a critical module fails, the cascading effects can shut down entire production lines, triggering costly delays that ripple through supply chains and customer commitments.

Installing inferior or incompatible replacement parts introduces risks that extend far beyond immediate functionality concerns. Non-OEM components may initially appear to work correctly, but subtle differences in voltage tolerances, signal processing speeds, or thermal characteristics can create intermittent failures that prove difficult to diagnose. These mismatches often cause unexpected system behavior, corrupted data transmission between modules, or premature wear on connected equipment. In safety-critical applications, such compromises can trigger false alarms or, worse, fail to activate protective shutdowns when genuine hazards arise.

Genuine OEM parts maintain the precise engineering specifications that manufacturers designed into integrated control systems. These components undergo rigorous testing to ensure they meet exact electrical characteristics, environmental tolerances, and communication protocols required for seamless integration. Beyond technical compatibility, authentic parts preserve warranty coverage and demonstrate regulatory compliance—critical factors during safety audits. While OEM components may carry higher upfront costs, they deliver measurable value through extended service life, predictable performance, and the confidence that comes from maintaining system integrity as originally engineered.

Common Challenges in Sourcing ICS Triplex Parts

Legacy automation components present unique procurement difficulties as manufacturers phase out older product lines while facilities continue operating equipment installed decades ago. The ICS Triplex systems, though renowned for reliability, often contain modules no longer in active production. Maintenance teams face the frustrating reality that authorized distributors may list parts as discontinued or available only through special order channels with uncertain fulfillment timelines. This scarcity forces technicians to explore secondary markets where inventory conditions and storage histories remain unknown, introducing uncertainty into already stressful repair situations.

Lead time challenges compound these availability issues, particularly when emergency repairs demand immediate action. Standard procurement channels may quote delivery windows stretching from weeks to months, leaving operations managers weighing the costs of extended downtime against expensive expedited shipping options. For facilities operating continuous processes or just-in-time manufacturing schedules, even a few days of delay translates to significant financial losses and contractual penalties. The gap between identifying a failed component and receiving its replacement becomes a critical vulnerability in operational planning.

Verifying part authenticity adds another layer of complexity to the sourcing process. The industrial automation market contains refurbished units, counterfeit components, and salvaged parts that may superficially match specifications but lack the quality assurance of genuine OEM products. Without established supplier relationships or verification protocols, technicians risk purchasing components that fail prematurely or introduce incompatibilities. Distinguishing legitimate suppliers from opportunistic vendors requires due diligence that emergency situations rarely afford, creating pressure to accept parts without proper validation of their origin and condition.

Your Complete Sourcing Solution for T8461 Parts

Verified Product Availability

Establishing real-time visibility into inventory status eliminates the guesswork that traditionally plagued automation part procurement. Reputable suppliers maintain digital catalog systems that display current stock levels, allowing technicians to verify availability before initiating purchase orders. When searching for specific modules, cross-reference manufacturer part numbers against supplier listings to confirm exact matches, paying attention to revision codes and firmware versions that may affect compatibility. Request documentation such as datasheets and compliance certificates directly through supplier portals to validate that listed components meet your system requirements.

Confirming specifications requires more than matching alphanumeric part codes. Examine technical parameters including input/output configurations, communication protocol versions, and mounting dimensions to ensure the replacement integrates seamlessly with existing infrastructure. Reliable suppliers provide access to engineering support teams who can clarify specification questions and identify suitable alternatives when exact matches prove unavailable. This verification step prevents costly ordering errors that result in receiving functionally incompatible components despite correct part number identification.

Streamlined Sourcing Process

Begin the procurement process by documenting the failed component’s complete identification details—part number, serial number if available, and system context including rack position and connected devices. Contact your chosen supplier through their designated technical inquiry channels, providing this information along with urgency requirements and any budgetary constraints. Established suppliers like Apter Power will assign a dedicated contact who guides you through availability confirmation, pricing, and delivery options tailored to your timeline needs.

Once you’ve confirmed part availability and pricing, submit a formal purchase order that includes delivery address, required arrival date, and any special handling instructions for sensitive electronic components. Request shipment tracking information and proactive status updates, particularly for expedited orders where timing proves critical. Quality suppliers package automation modules with appropriate anti-static protection and environmental safeguards, often including handling guidelines and installation recommendations.

Throughout the ordering cycle, maintain open communication channels with your supplier’s technical support resources. These specialists can provide pre-installation guidance, answer configuration questions, and troubleshoot any integration concerns that arise during replacement procedures. Documenting your interactions creates a reference trail for future procurement needs and helps build supplier relationships that streamline subsequent orders when additional components require replacement.

Benefits of Choosing the Right Automation Parts Supplier

Partnering with a dependable automation parts supplier directly translates to measurable reductions in unplanned downtime. When critical components fail, access to verified inventory through established supplier relationships means technicians can secure replacement parts within hours rather than days or weeks. This rapid response capability prevents the domino effect of production stoppages that cascade through manufacturing schedules, shipping commitments, and customer relationships. Facilities that cultivate relationships with reliable suppliers often negotiate priority fulfillment agreements, ensuring their urgent requests receive expedited processing during emergency situations when every minute of downtime carries substantial financial consequences.

Proper part matching eliminates the hidden costs associated with trial-and-error procurement approaches. When suppliers provide accurate technical specifications and engineering support, maintenance teams avoid purchasing components that appear compatible but introduce subtle integration issues. These mismatches often require additional troubleshooting time, repeated shipping expenses, and the frustration of extended repair cycles. By contrast, suppliers who invest in technical expertise help customers identify the correct components on the first attempt, reducing overall procurement costs despite potentially higher per-unit prices. The savings extend beyond immediate purchases to include reduced labor hours spent diagnosing compatibility problems and fewer emergency expedited shipments to correct ordering mistakes.

Long-term system compatibility advantages emerge when suppliers understand the broader context of your automation infrastructure. Knowledgeable partners track obsolescence trends, alerting customers to upcoming component discontinuations before they create urgent sourcing crises. They maintain documentation of your installed systems, enabling faster future procurement and identifying opportunities for strategic spare parts inventory. This forward-looking approach transforms supplier relationships from transactional exchanges into collaborative partnerships that support ongoing operational reliability, helping facilities plan maintenance activities and budget for component lifecycle management rather than reacting to unexpected failures.

Strategic Sourcing for Operational Excellence

Securing reliable automation spare parts represents one of the most critical responsibilities facing industrial maintenance teams today. The difference between a supplier who delivers verified components quickly and one who introduces delays or quality concerns directly impacts your facility’s operational continuity and bottom line. As demonstrated throughout this guide, successful procurement extends beyond simply finding parts—it requires establishing relationships with suppliers who understand your technical requirements, maintain authentic inventory, and provide the support necessary to ensure proper component integration.

The T8461 and similar ICS Triplex components exemplify the sourcing challenges that demand strategic approaches rather than reactive scrambling during emergencies. By implementing the verification methods, communication protocols, and supplier evaluation criteria outlined here, industrial technicians can transform spare parts procurement from a persistent headache into a manageable aspect of facility operations. Take immediate action by auditing your current supplier relationships, documenting critical system components that may require future replacement, and establishing contact with verified automation parts sources before the next component failure occurs. Proactive sourcing strategies today prevent the costly downtime and operational disruptions that plague facilities caught unprepared when critical automation systems demand immediate attention.