Behind the Scenes: How a Neon Sign Maker Brings Designs to Life

Neon signs have long held a special place in visual culture, evoking nostalgia, personality, and artistic flair. Whether illuminating a small café with a soft glow or electrifying the Vegas Strip with vibrant color, neon signage is as much about craft as it is about function. But what does it take to bring these glowing statements to life?

In this behind-the-scenes journey, we’ll explore the meticulous process of creating neon signs, from conceptual sketches to the final radiant display. Discover how a neon sign maker blends art, science, and craftsmanship to light up the world—one curve at a time.

Step 1: From Vision to Blueprint — The Design Process

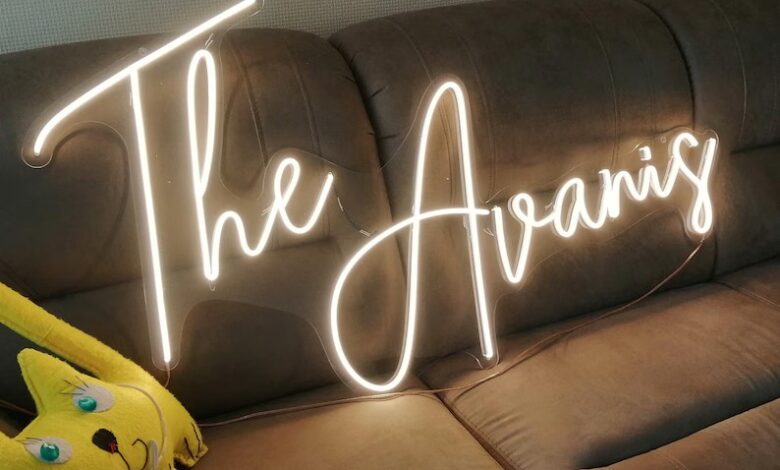

Every neon sign starts with an idea. Whether a business logo, a quirky phrase, or a custom piece for home décor, the process begins with design conceptualization.

Creative Collaboration

Clients often collaborate closely with a neon sign maker to refine their vision. A professional will consider design feasibility, font styles, dimensions, and color schemes. Bold fonts with rounded edges are often preferred due to the constraints of bending glass tubing.

Digital Mockups

Once ideas are finalized, the neon sign maker translates the concept into digital artwork using tools like Adobe Illustrator or CorelDRAW. These mockups help visualize the final product and guide the next stages of fabrication.

Step 2: Material Selection — Choosing the Right Components

Not all neon signs are created equal. A seasoned neon sign maker selects from a range of materials based on the design’s size, color, and application.

Glass Tubing

Glass is the primary canvas for a neon sign. Tubes typically measure 8 to 15 millimeters in diameter and come in various colors and finishes—clear, colored, or phosphor-coated.

Gas Choices

Neon gas produces a fiery red-orange glow, while argon mixed with mercury gives off a soft blue. With different phosphor coatings, these gases can generate a wide spectrum of colors. The neon sign maker selects gases depending on the desired hue and brightness.

Step 3: Glass Bending — The Heart of the Craft

Arguably, the most skill-intensive part of the process, glass bending, transforms a rigid tube into a living script of light. This is where craftsmanship shines.

The Art of the Flame

Using a ribbon burner or hand torch, the neon sign maker heats the glass tubing to a pliable state. Timing and temperature control are critical—too hot, and the glass will bubble; too cold, and it will crack.

Precision and Practice

Once heated, the glass is bent into shape. This must be done quickly yet carefully. The maker frequently compares their work to a pattern drawn to scale beneath the workbench to ensure accuracy. Even experienced artisans require years of practice to master these movements.

Step 4: Tubing Assembly and Electrodes

After each segment is shaped, the pieces are joined, and electrodes are attached at either end. Electrodes are essential—they provide the electrical current needed to energize the gas inside the tube.

Pumping System

The entire assembly is connected to a manifold system. Air is evacuated, and the tube is then flushed with a noble gas. The gas mixture and amount vary based on color requirements and tube length.

Bombarding and Sealing

Next comes “bombarding”—a process where high-voltage current is passed through the tube to heat the glass and burn off impurities. Once cleaned and gas-filled, the ends are sealed, completing the internal structure of the neon sign.

Step 5: Testing and Quality Control

At this point, the sign may look finished, but it hasn’t yet been proven reliable. Testing is essential to ensure the piece will glow consistently and safely.

Aging the Sign

Neon signs undergo a process known as aging or burning in. This involves powering the sign continuously for up to 24 hours. It helps stabilize gas discharge and highlights any weak spots or defects in the tube or electrodes.

Final Adjustments

If a section doesn’t light correctly or dims over time, the neon sign maker troubleshoots the issue, sometimes reworking sections of glass or replacing electrodes. Precision here ensures longevity and safety.

Step 6: Mounting and Installation

Once the tubing passes all quality checks, it’s time to mount it onto a display structure and prepare for installation.

Backing Boards and Casings

Depending on the application, the glass tubes may be mounted on acrylic, metal, or aluminum backboards. Clips, standoffs, and silicone insulators keep the delicate tubes securely in place while maintaining visual appeal.

Electrical Setup

The neon sign maker then wires the sign to a transformer. The transformer must match the voltage and amperage required for the specific gas and tube length, and it often includes safety features like circuit breakers or GFI (ground fault interrupters).

Final Placement

Whether it’s being installed in a storefront window, office lobby, or event venue, careful transport and precise placement are key. Neon is fragile, and installation is often the final test of a sign’s durability and design cohesion.

Beyond Neon: The LED Evolution

While traditional glass neon remains iconic, modern alternatives like LED “neon-style” lights have entered the scene. These are flexible, plastic-encased strips that mimic the glow of neon while offering energy efficiency and durability.

A Neon Sign Maker’s Perspective

Many purists argue that nothing beats the authenticity and warmth of true neon. However, contemporary neon sign makers often diversify their skills to include both traditional and LED technologies, adapting to different client needs and aesthetic goals.

The Maker’s Mindset: Passion Meets Precision

What sets a true neon sign maker apart is not just technical skill, but passion. This is a trade steeped in artistry, patience, and resilience. Every curve in the glass, every flicker of light, tells a story of meticulous labor and glowing creativity.

The Legacy of the Craft

In an era of mass production, the handcrafted nature of neon signage stands out. The knowledge is often passed from master to apprentice, preserving techniques that have existed for over a century. Each sign is not only a commercial asset but also a piece of luminous art.

Why It Matters

Whether lighting up a bar in Brooklyn or branding a retail store in Tokyo, neon signs connect us to something elemental. They evoke emotion, draw attention, and offer a visual signature that’s hard to replicate.

So next time you admire a glowing phrase or a buzzing open sign, take a moment to appreciate the artistry behind it. The neon sign maker behind that light has likely spent hours bending glass, perfecting colors, and balancing voltage to bring your vision to life.

In Conclusion

Behind every dazzling neon sign is a process that combines tradition, technology, and tenacity. The next time you see one flicker to life, remember: it’s not just a sign—it’s a testament to craftsmanship.

Whether you’re a business owner seeking standout signage or an enthusiast looking for custom décor, working with a skilled neon sign maker ensures your idea doesn’t just glow—it shines.