Exploring the Versatility of Push Button Switches in Different Industries

Push button switches play the most important role in modern electronics and machinery where it finds wide application in different fields owing to its simplicity, reliability and versatility. These switches are used in consumer electronic products to powerful industrial control uses. They can be implemented in various systems without interruption because of their design. In this article, we will deal with an overview of the various uses of push button switches, how they are instrumental to the activities of the various industries and why LED power supply manufacturers play a key role in securing the dependability of these switches.

What Are the Push Button Switches?

Push button switches is a simple electromechanical switch which opens or closes an electrical connection by being pressed. Highly simple to work, they can be found in virtually all electric gadgets used including household appliances and industrial machineries. These switches take numerous forms, sizes, and combinations, and manufacturers can customize them, according to a particular task or an industry. The simplest forms of push button switches are momentary and latching, the former of which returns to the default position upon being pressed, and the latter remaining in the new position until it is pressed for the second time. Push button switches are commonly linked with inbuilt LED indicators which make them more useful to the users by giving them good visual indication, e.g. whether a system is powered on or not. In this, manufacturers of LED power supply come in as essential in providing the required energy which is important to ensure that these indicators work properly and efficiently.

The Push Button Switches in Various Industries

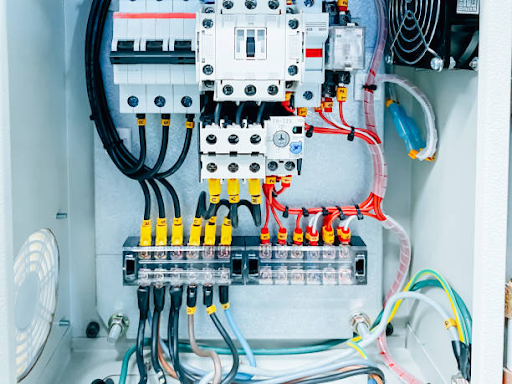

Push button switches have important usage in a broad range of sectors. Quantities like vehicle ignition systems, lighting, and seat adjustments in the automobile industry are some of the applications of the same. Push button ignition has also become common in modern cars as a simple press on a button instead of the usual turning of a key adds convenience and modernization in the car design. In the same way in industrial and manufacturing industries push button switches are required in controlling and starting machines and stop systems in case of emergency. They are designed to last long in a rough environment and thus safe and dependable in hazardous areas.

Push button switches have applications in the healthcare sector in all forms related to the medical diagnostic tests and equipment, patient health monitors and purposes of all medical equipment. Their touch-responses and simplicity play a significant role in high-stress, emergency cases in which simplicity is key to ease of use. Push button switches prevail in consumer electronics, e.g. in home appliances such as microwaves, washing machines; in gadgets such as remote controls, gaming devices; as well as providing a universal control in mixed appliances. These switches enable the users to operate the devices using minimal effort.

Lastly, push button switches can withstand harsh environments making it essential in places such as the military and the field of aerospace where accuracy and ergonomics are prerequisites. These switches can be controlling avionics systems through to managing sensitive equipment that is needed in a complex system that has the requirement of accuracy in a pressurizing environment.

Push Button Switch Customization and features Key Features

Push button switches are reliable and long lasting, which happen to be the two most critical characteristics of any component required in industries which require high standard components. These switches are also made to last thousands of cycles that is why they are very suited in applications where they need continual use. They are also so simple to use, that it becomes very difficult to make any wrong step especially when the operations are very critical.

The other major benefit is customization. Push button switches are customized to suit particular settings and needs, such as explosion proof switches in the dangerous settings and weatherproof switches where outdoors are applied. Incidents can often be prevented with safety features, like emergency stop buttons, integrated into the switches, especially in industrial and manufacturing applications, so a worker can easily stop potentially dangerous machinery or systems should an emergency happen.

Moreover, having LEDs makes it easy to have visual representations about system status hence increases user experience. The push button switches are easy to design and can work with virtually any application be it consumer electronics, medical or even industrial machines. This flexibility in customization is enabled to a large extent by the manufacturers of push button switches who liaise with the clients in manufacturing switches that satisfy the requirements of a particular industry.

The Role of LED Power Supply Producers

The low energy consumption and visible response has made LEDs a basic thing in push button switches. Suggesting which device in the system is on or malfunctioning, LED indicators are necessary in order to operate with the user-friendly control. But to apply the non resistive properties of such LEDs, the proper power supply plays an important role. The manufacture of LED power supply is an important part in the provision of a stable and sufficient power to the LEDs installed in the push button switches.

In the automotive, industrial, and healthcare systems where reliability is of importance, the LED indicator performance will determine the overall ability of the switch. Manufacturers of LED power supply systems create the system that avoids power surge, uses low energy, and makes the lifetime of the LED meaningful particularly in the case of devices likely to be required to run longer periods without needing even to be serviced. Since these switches are utilized in the places where at least the safety and clear communication are essential, the experience of LED power supply producers makes sure that the user can trust the visual indications of the push button switches.

Conclusion

Push button switches are highly flexible, low maintenance, simple and stable devices that are found to be very instrumental in many industries. Such switches can be found in automotive systems, health care systems, and more, simplifying the use of the devices and making them more effective. These features incorporated the durability factor, customization that they can be adapted to and the LED internal indicators thus making them very essential in the modern technological world. The collaboration between push button switch manufacturers and LED power supply manufacturers ensures that these switches function reliably, offering clear, energy-efficient feedback for users across multiple sectors. Push button switches will prove to be a stable part of the control of devices as long as industries keep developing and the future offers even smartest and energy conserving facilities.