How Can Seaming Machines Improve Your Canning Process

In the intricate realm of food packaging, refining your canning approach is crucial in regards to maintaining standards and quality, minimizing logistical expenses, and increasing production output. One of the most promising measures of resolving problems related to processes within the food canning industry is the implementation of machinery for food processing plants, more specifically can seamers. These machines assist greatly in the accuracy, reliability, safety, and shelf-life of food products packed in cans. For B2B companies dealing with food packaging, purchasing reliable can seamers of high quality can remarkably facilitate their productivity and overall outcome. This article will discuss how these machines enhance the canning process and the reason that modern industrial food packaging equipment cannot be imagined without them.

Understanding Can Seaming Machines

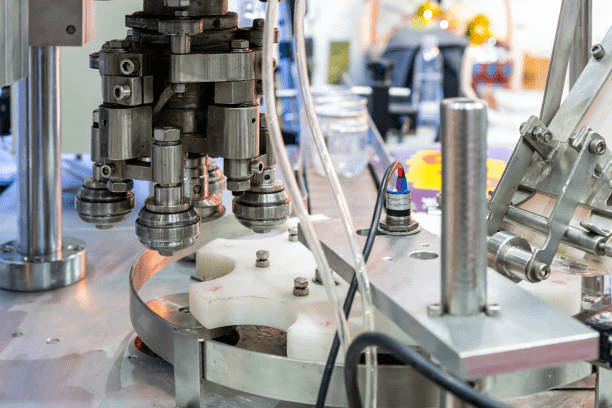

Before diving into the benefits, it’s important to understand what a can seaming machine does. These machines are designed to securely seal the lids of cans, ensuring that the contents are preserved and protected from contamination, air, and moisture. The process involves two main actions: forming a hermetic seal between the can body and the lid and ensuring that the contents inside remain safe during transport and storage.

A can seaming machine performs this function with high precision, which is critical in maintaining the integrity of the canned products. These machines are commonly used in the food, beverage, and pharmaceutical industries, where packaging hygiene and security are paramount.

The Role of Industrial Food Packaging Equipment in Modern Manufacturing

When it comes to food packaging, accuracy and speed are critical pertaining to industrial food packaging equipment. With the inclusion of sophisticated equipment such as can filling machines, labelers, and seaming machines, packaging lines are able to meet production schedules and enhance the caliber of the products.

Automation in canning greatly enhances the flow of work and decreases the reliance on human labor, thus speeding up overall production. The proper mix of industrial food packaging equipment will assist a business in optimizing their workflows while ensuring compliance with regulations and mandates established by the customers. The contribution of can seaming machines, which guarantee that the seams are perfectly even and defect free, adds greatly to that optimization, thus aiding in the safety and quality of the product.

How Can Seaming Machines Enhance the Canning Process

Improved Seal Integrity

One of the most significant advantages of a can seaming machine is its ability to create a strong, hermetically sealed can. This ensures that the product inside remains sealed from external contaminants, which is especially important in the food industry. Without a proper seal, products can spoil quickly, leading to waste and potentially harmful consequences.

A machine that is capable of making consistent, high-quality seals will help maintain the freshness and safety of the product for longer periods, whether it is a solid food item, beverage, or even more delicate products like sauces or canned meats. The machine ensures that the seal is formed correctly every time, reducing the risk of compromised packaging that could lead to spoilage.

Enhanced Production Speed

In the context of B2B food production, time might as well be a currency. The use of can seaming machines in the Industrial food packaging industry automates the sealing process enabling faster production rates. These machines can outperform all human workers with their can sealing capabilities, posting speeds in the thousands per hour.

Faster packaging line speed alongside consistent quality provides manufacturers with significantly higher throughput. Added value is generated through improved production efficiency and profitability as more products are packaged in less time.

Consistency and Precision

Consistency is key in the food packaging industry, and a can seaming machine ensures that each can is sealed with the same level of precision every time. This eliminates variability, which is common in manual sealing processes where human error can lead to inconsistent results.

Machines designed with advanced features like servo motors and automated controls can monitor and adjust the sealing process in real-time to ensure the optimal quality of every seal. This level of precision not only improves the safety and shelf life of the product but also contributes to the overall professionalism and reliability of your brand.

Reduction in Packaging Costs

While the upfront cost of industrial food packaging equipment like a can seaming machine may seem high, the long-term benefits make it a worthwhile investment. By automating the canning process, businesses can reduce labor costs, minimize product waste, and eliminate the need for constant manual supervision. The precise sealing provided by the machine also reduces the chances of defective products being produced, leading to fewer returns and less spoilage.

Additionally, the ability to increase production speed means that businesses can meet higher demand without the need for additional workers or equipment. This leads to significant cost savings over time, making it a cost-effective solution for businesses in the food packaging industry.

Improved Hygiene and Safety

Food safety regulations are critical in the food packaging industry, and using a can seaming machine can help ensure that all cans are sealed properly, reducing the risk of contamination. The automation of the sealing process also reduces human contact with the product, which minimizes the risk of introducing contaminants during the packaging process.

Modern can seaming machines are designed with hygiene in mind, incorporating features like easy-to-clean surfaces and minimal exposure to product contents during the sealing process. This is particularly important for industries dealing with perishable or sensitive food products that require strict adherence to safety and hygiene standards.

The Benefits of Customizing Your Can Seaming Machines

Every business has their own specialized off-the-shelf equipment which may not always be the best approach to a company’s needs. One of the many benefits regarding customization is the fact that you can change your can seaming machines to suit your requirements. Depending on the product being packaged, customization can entail modifying the machine’s speed, size, or even type of sealing utilized in the process.

Also, seamers which are customizable can give businesses the ability to expand or adjust their production lines as time goes by. Adjusting the solution will also permit the business to package small, niche products or develop to meet the growing mass production scale, thereby making the entire process cost efficient.

Conclusion: Investing in a Can Seaming Machine

If you are running a B2B company that deals with food packaging, integrating a can seaming machine can help modify and improve your production line in many ways. These machines are imperative for the modernization of the canning process all because they increase production speed, consistency, reduce costs, and most importantly, enhance seal integrity at every step.

While selecting machines for industrial food packaging, choosing a reliable manufacturer who provides high-quality and customizable equipment is a must. These reputed companies guarantee meeting your requirements and specifications. With the right equipment, you are assured of the highest standards of quality packaged food products. A can seaming machine is more than a value addition for your production line; it’s an avenue towards increased productivity, safety, and cost efficiency in your food packaging services.