Non-Isolated Boost Converters for Power Efficiency

Power electronics play a critical role in modern technology, and one of the most widely used devices in this domain is the DC-DC converter. Among the various types available, non-isolated boost converters stand out for their simplicity, efficiency, and wide application across industries. These converters are designed to increase (or “boost”) the input voltage to a higher output voltage without any electrical isolation between the input and output. Whether it’s for renewable energy systems, automotive applications, or consumer electronics, understanding non-isolated boost converters is essential for both engineers and enthusiasts.

What Are Non-Isolated Boost Converters?

Non-isolated boost converters are a type of DC-DC converter that steps up the input voltage to a higher output voltage. Unlike isolated converters, they do not use a transformer to separate input and output, which makes them more compact, lightweight, and cost-effective. They are commonly used in battery-powered devices and renewable energy systems where efficiency and simplicity are key.

Importance of Boost Converters in Power Electronics

Boost converters play a pivotal role in modern electronics by providing stable voltage levels required for devices to function optimally. They ensure that power from batteries, solar panels, or other DC sources is adjusted to the necessary operating voltage. Without converters like these, many portable and renewable energy systems would not function efficiently.

How Non-Isolated Boost Converters Work

At their core, boost converters use an inductor, a diode, a switch (such as a transistor), and a capacitor. When the switch is turned on, energy is stored in the inductor. Once the switch is off, this stored energy is released, combining with the input voltage to provide a higher output. This switching process happens rapidly, often tens or hundreds of thousands of times per second, ensuring smooth and reliable voltage boosting.

Key Components of Non-Isolated Boost Converters

- Inductor: Stores energy in the form of a magnetic field.

- Diode: Prevents current from flowing backward into the input.

- Switch (MOSFET/IGBT): Regulates the on/off cycles, controlling energy storage and release.

- Capacitor: Smooths the output voltage, reducing ripple.

Together, these components form the foundation of every non-isolated boost converter design.

Advantages of Non-Isolated Boost Converters

- High Efficiency – Typically 90% or higher in well-designed circuits.

- Compact Size – No transformer required, making the design lightweight.

- Cost-Effective – Fewer components mean reduced cost compared to isolated designs.

- Simplicity – Easy to design, implement, and maintain.

- Wide Applicability – Can be used in automotive, renewable, and consumer electronics.

Limitations of Non-Isolated Boost Converters

While beneficial, these converters also have limitations:

- No Electrical Isolation – Input and output are directly connected, which can be unsafe in some cases.

- Limited Voltage Gain – Extreme boosting ratios may cause inefficiency and instability.

- Electromagnetic Interference (EMI) – High-frequency switching can create noise.

- Thermal Management Issues – Heat dissipation needs to be carefully managed.

Applications of Non-Isolated Boost Converters

1. Renewable Energy Systems

Solar panels often generate low DC voltage, which needs to be boosted for storage or grid integration. Boost converters ensure optimal power delivery in these setups.

2. Automotive Systems

In electric and hybrid vehicles, 12V to 24V boost converters step up battery voltages to meet the higher requirements of motors and auxiliary auto-electronics.

3. Consumer Electronics

Devices like laptops, smartphones, and portable chargers rely on boost converters to maintain stable voltage from fluctuating battery levels.

4. Industrial Equipment

Automation systems, robotics, and control systems use these converters for consistent power supply.

Non-Isolated Boost Converters vs Isolated Boost Converters

The key difference lies in isolation. Isolated converters use transformers to separate input and output, providing safety and higher voltage gain, but at the expense of size, cost, and complexity. Non-isolated converters, on the other hand, prioritize efficiency and compact design where isolation is not required.

Design Considerations for Non-Isolated Boost Converters

- Input Voltage Range: Must match the source, e.g., batteries or solar panels.

- Output Voltage Requirements: Defines the duty cycle of the switching device.

- Switching Frequency: Higher frequencies allow smaller components but increase EMI.

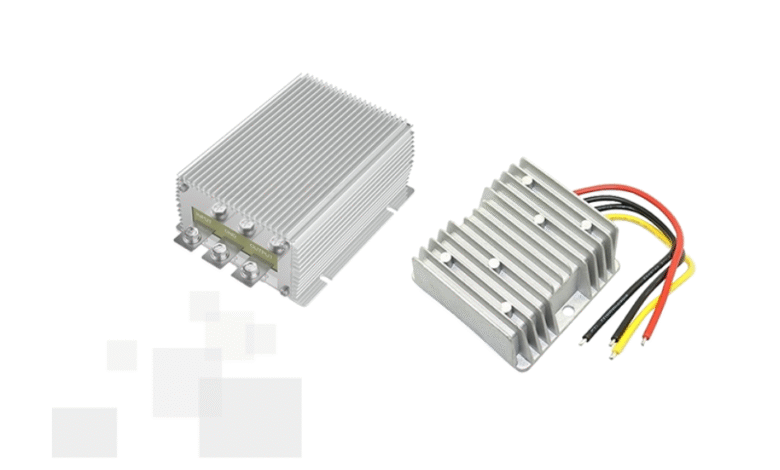

- Thermal Management: Heat sinks and cooling mechanisms are essential.

- Control Techniques: Pulse Width Modulation (PWM) is commonly used for regulation.

Efficiency of Non-Isolated Boost Converters

Efficiency is one of the strongest advantages of these converters. With optimized design, efficiencies above 95% can be achieved. Efficiency depends on factors like inductor quality, switching frequency, and load conditions. For battery-powered devices, higher efficiency translates directly into longer operating times.

Safety Aspects of Non-Isolated Boost Converters

Because there’s no electrical isolation, safety must be carefully considered. Protective mechanisms such as overvoltage protection, current limiting, and thermal shutdown are typically included to prevent system damage.

Emerging Trends in Non-Isolated Boost Converters

- Wide Bandgap Semiconductors – Materials like GaN and SiC are improving efficiency and reducing losses.

- Digital Control – Microcontrollers and DSPs are increasingly used for precise regulation.

- Integration – More converters are being designed as compact ICs for consumer electronics.

- Eco-Friendly Designs – Growing emphasis on low-loss and recyclable materials.

Challenges in Implementing Boost Converters

- Managing Heat Dissipation in compact designs.

- Maintaining Efficiency across variable loads.

- Reducing Electromagnetic Noise to meet regulatory standards.

- Cost Control while incorporating advanced materials.

Future of Non-Isolated Boost Converters

As industries push for higher efficiency and compact designs, these converters will continue to evolve. The adoption of renewable energy systems, electric vehicles, and portable electronics ensures that non-isolated boost converters will remain highly relevant. Advances in semiconductor materials and digital control systems will further enhance their performance and applicability.

Conclusion

In summary, non-isolated boost converters are indispensable in today’s power electronics landscape. They provide efficient, compact, and cost-effective solutions for boosting voltage in applications ranging from consumer gadgets to renewable energy and automotive systems. While they lack isolation and have certain limitations, their advantages make them a go-to choice where simplicity and efficiency matter most. As technology advances, these converters are expected to become even more powerful, efficient, and widespread.