PCB Manufacturing: Essential Tips for Better Quality

Printed Circuit Boards (PCBs) are the backbone of modern electronics. From smartphones and computers to cars and medical devices, almost every electronic product relies on them. Because of this, the quality of PCB manufacturing directly impacts the reliability and performance of the final device. For engineers, manufacturers, and hobbyists, understanding the best practices in PCB manufacturing is essential for achieving better results. This article explores the most important tips that can help you improve PCB quality and avoid costly errors.

Understanding the Basics of PCB Manufacturing

Before diving into quality tips, it’s important to understand how PCBs are made. At its core, PCB manufacturing involves layering conductive and non-conductive materials to create paths that allow electrical signals to flow. The process includes designing, etching, drilling, plating, solder masking, silkscreen printing, and assembly.

Each step must be carried out with precision. Even small mistakes—such as a poorly aligned drill hole or inadequate copper thickness—can lead to circuit failure. By focusing on the fundamentals, manufacturers can reduce defects and produce boards that meet industry standards.

Designing with Quality in Mind

A high-quality PCB starts with a high-quality design. If the design has flaws, no amount of careful manufacturing can fully compensate.

Keep Traces and Spacing Consistent

One of the most common causes of PCB failure is inconsistent trace widths and spacing. Narrow traces may overheat and break, while spacing that is too tight increases the risk of short circuits. Following IPC (Institute for Printed Circuits) design standards is a good starting point.

Use Proper Via Sizes

Vias, which connect different layers of the board, must be carefully designed. Undersized vias can cause electrical resistance and mechanical weakness. Always match via dimensions with the thickness of the PCB and expected current load.

Optimize Component Placement

Placing components too close together not only makes assembly difficult but also increases the chance of heat buildup. Critical components, such as microcontrollers and power ICs, should be placed with heat dissipation and accessibility in mind.

Choosing the Right Materials

The quality of a PCB depends heavily on the materials used. Using substandard materials may reduce costs upfront, but it increases the risk of malfunction later.

Select High-Quality Copper Cladding

Copper thickness determines how much current the PCB can handle. Thicker copper layers improve durability but also increase costs. For most applications, a copper thickness of 1 oz/ft² is standard, but high-power designs may require 2 oz/ft² or more.

Focus on Substrate Reliability

The substrate, often made of FR4 (a fiberglass-reinforced epoxy), provides structural integrity. For devices exposed to high heat or stress, advanced substrates like polyimide or metal-core boards may be more suitable.

Use Reliable Solder Mask Materials

A solder mask protects copper traces from oxidation and prevents solder bridges during assembly. High-quality solder mask materials improve the board’s lifespan and reduce defects in soldering.

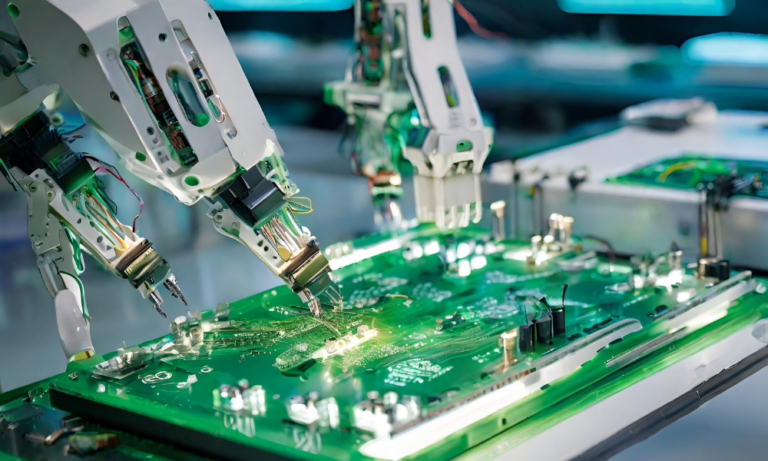

Precision in Manufacturing Processes

Even with a flawless design and quality materials, the actual manufacturing process determines final performance. Precision and consistency are key.

Accurate Drilling and Plating

Holes for vias and through-hole components must be drilled with extreme accuracy. Misaligned or rough holes can weaken connections. Plating the holes with uniform copper ensures conductivity and mechanical strength.

Controlled Etching

Etching removes unwanted copper to form conductive pathways. Over-etching thins the traces, while under-etching can cause shorts. Maintaining the correct chemical balance and time in the etching bath ensures clean, accurate traces.

Consistent Lamination

Multilayer PCBs require lamination of several copper and substrate layers. Misaligned lamination causes defects that are difficult to repair. Automated lamination under controlled pressure and temperature minimizes these risks.

Ensuring Proper Thermal Management

Heat is a common enemy of electronics. Poor thermal management can damage both the PCB and its components.

Add Thermal Vias

Thermal vias help transfer heat from one side of the PCB to the other, preventing hot spots. They are especially useful under heat-generating components like power regulators and processors.

Use Heat Sinks and Copper Planes

Designing large copper planes around high-power areas helps distribute heat. In some cases, external heat sinks can be added for better cooling.

Choose Heat-Resistant Materials

For devices that operate in high-temperature environments, using substrates and solder masks with high thermal resistance ensures stability over time.

Quality Control and Testing

No PCB manufacturing process is complete without thorough testing. Quality control helps detect defects before boards reach customers.

Visual Inspection

Inspecting PCBs under magnification helps identify obvious defects such as misaligned components, solder bridges, or scratches.

Automated Optical Inspection (AOI)

AOI systems scan PCBs using cameras to detect errors in traces, soldering, and placement. This automated process ensures higher accuracy and faster detection than manual inspection.

Electrical Testing

Functional testing ensures that every trace and via conducts properly. Flying probe testers and in-circuit testing methods verify connections and detect shorts or opens.

Partnering with Reliable Manufacturers

If you are outsourcing PCB production, choosing the right manufacturer is critical.

Evaluate Experience and Certifications

Look for manufacturers with certifications such as ISO 9001 or IPC-A-600, which indicate adherence to quality standards.

Check Capabilities and Equipment

Not all manufacturers can handle advanced PCBs like multilayer or HDI (High Density Interconnect) designs. Ensure the chosen partner has the necessary tools and expertise.

Review Turnaround and Support

A reliable manufacturer provides not only quick turnaround but also technical support throughout the process. This partnership ensures better results and fewer delays.

Continuous Improvement in PCB Manufacturing

PCB manufacturing is a field that constantly evolves. New technologies, materials, and methods emerge every year.

Adopt Design for Manufacturability (DFM)

DFM practices help simplify designs so that they are easier and cheaper to produce while maintaining quality. This includes optimizing trace layouts, via counts, and panel designs.

Stay Updated on Industry Trends

Technologies like flexible PCBs, rigid-flex designs, and high-frequency laminates are becoming increasingly popular. Staying informed ensures that your designs and manufacturing processes remain competitive.

Gather Feedback and Refine Processes

Every production run provides valuable data. Analyzing failure rates, customer feedback, and process performance helps manufacturers continuously improve quality.

Final Thoughts

PCB manufacturing is more than just producing circuit boards; it’s about ensuring reliability, performance, and durability. From careful design and material selection to precision manufacturing and rigorous testing, every step plays a crucial role in achieving better quality.

By applying essential tips—such as optimizing designs, choosing the right materials, ensuring thermal management, and implementing strict quality control—you can significantly improve the overall performance of your PCBs. Whether you are an electronics engineer, a startup innovator, or a large-scale manufacturer, prioritizing quality in PCB manufacturing will lead to better products, happier customers, and long-term success.