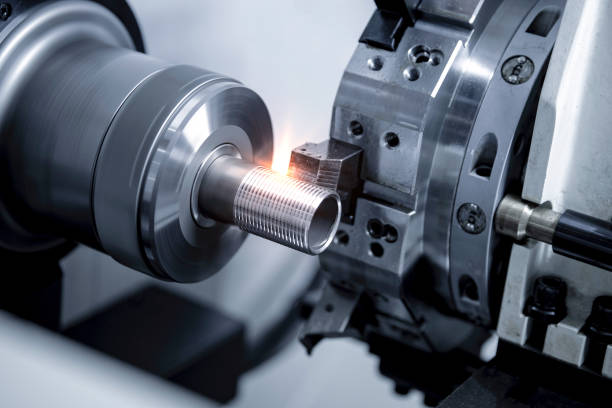

Top Applications of CNC Turning Parts in Modern Industries

CNC turning is an integral part of modern manufacturing since it can produce intricate, large and small turned components within a short span of time. In aerospace, automotive, medical industry and electronics, the turning parts of CNC have become indispensably perfect due to aspects such as versatility, accuracy, and efficiency. Sourcing from the right CNC machining suppliers enables organizations to obtain component parts that are required in the modern world economy. Here, we discuss five prime areas of operation for CNC turning parts and how they are taking innovative gears and functionality ahead.

Devices for High Risk Applications

The aerospace industry especially is very sensitive to small inaccuracies. Aircraft, satellites as well as spacecraft found use of components that are reliable under conditions of extreme temperature, pressures and various stresses. CNC turning parts are widely utilized in aerospace industries for the application in factors like; turbine blades turning parts; engine shafts; hydraulic turning parts; and landing gear. One of the most crucial technological specifications of parts is the allowance or tolerance and even more important the design which is easily made possible by the CNC turning machines hence it’s safe to say that these parts made by the company meet all the required specifications to allow safety and excellent performance.

CNC turning facilitates the use of high performance materials such as titanium, aluminum and heat resistant super alloys used in the manufacture of aircrafts. These materials not only give the necessary strength, but also decrease the weight of components which indeed increase the fuel efficiency and performance levels. Furthermore, CNC turning can guarantee productivity in precise quality and consistency in a repetitive manner even in the most sensitive operations. They just simply collaborate with professional CNC machining suppliers so that aerospace makers can obtain both novelty and efficiency, thus providing the parts that are satisfying the strict Aerospace demand.

Economical and Durable Design in Motion

Currently the automotive industry utilizes CNC turning parts for numerous parts that make and drive cars through enhanced reliability. Including engines, transmission, suspension, brake system etc, cnc turning profoundly participates in car manufacturing. It is these parts that should possess a high degree of accuracy in order to interface and work effectively and in vehicles which employ very complex systems and designs.

CNC turning improves the production of auto parts in that it allows for the production of both first-run and high production parts with great accuracy. For electric vehicles, CNC turning has been critical in manufacturing light and strong parts including battery boxes, powertrain and thermal management. Additionally, CNC turning machines can well support the selection of the new generation of materials such as carbon fiber composites and aluminum that help to decrease the weight, as well as increase durability. Working with professional CNC machining suppliers makes it possible for auto makers to satisfy the emerging needs of the market while pushing down the production cost to manageable levels.

Life-Saving Precision in Devices and Equipment

When it comes to the medical profession, it is absolutely critical to make sure one is as accurate as possible. CNC turning parts vary extensively with appliances in the manufacture of medical equipment, operation instruments and diagnostic apparatuses. For this reason, parts like implants, bone screws and catheter connectors call for high degrees of precision, a factor which can be best achieved through CNC turning where materials that are biocompatible are used.

It can be said that the accuracy of CNC turning is crucial for the elaboration of the parts to meet requirements and enhance security of patients. For example, a surgical tool or implant must form an exact part of the human body hence it must be well polished. CNC turning machines are particularly effective in producing slots and threads which are usually inserted on parts such as orthopedic screws or dental implants. With proper integration to the right CNC machining suppliers who understand the requirements for medical manufacturing, healthcare providers can be sure of getting the devices in the best quality as per their efficiency required. It also benefits the patient as their care is figured out to a minor detail and it pushes the growth and development of medical devices.

Precision for Innovation

The electronics and energy industries also benefit from the usage of CNC turning parts in order to provide functionality for the technologies. In electronics, CNC turning is essential in the generation of tiny parts such as connectors, heat sink, and enclosure parts of smartphones, computers among others. These components demand great accurities, complex shapes and these specific designs are easily done by CNC turning machines. The precision of the parts required to manufacture these electronic devices can be very high to maintain the existing performance standard and this is made possible by the process.

In the energy industry, CNC turning parts are widely used for renewable energy products as well as for conventional products such as oil and gas products. Wind turbines utilize parts produced through CNC turning such as shafts, and bearing housings to function optimally under continuous pressure. Likewise, CNC turning is employed to manufacture valves and fittings for oil and gas industries where stresses and rough environments will demand the highest levels of manufacturing tolerances necessary to withstand the pressure and corrosive conditions. Through working with reliable CNC machining suppliers, companies in both industries can develop high-quality components that enhance industries and quality at the same time.

Conclusion

CNC turning parts are important in enhancing the operations of most industries today through accuracy, flexibility, and reliability. These components lie across industries as diverse as aerospace and automotive as well as medical, electronics and energy sectors that are at the forefront of technology manufacturing. When engaging the worthy CNC machining suppliers, it means that different companies shall be in a position to obtain some of the best parts which fulfill the needed standards of different industries.

From aerospace engineering to producing a variety of medical equipment or state-of-the-art electronics, CNC turning remains an essential process within twenty first century production. CNC turning service suppliers ensure that they deliver components to businesses in the right quality, standard and even help them achieve their objectives. Due to its versatility and outstanding performance, CNC turning continues to be a fundamental process for growth and development in the current society.