What Should You Know Before Buying a CPU for Industrial Use?

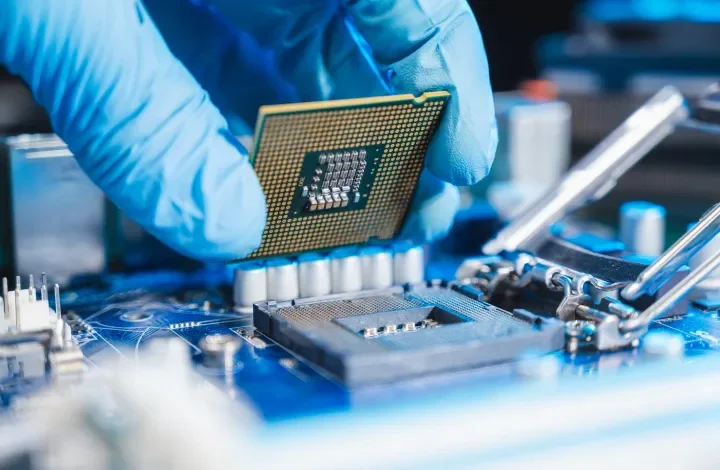

In industrial systems, the central processing unit (CPU) serves as the brain behind automation, control, and data processing. Whether it powers an edge device, a machine vision system, or an embedded control panel, the CPU must meet demanding requirements beyond consumer-grade performance. Before committing to CPU component sourcing, engineers and procurement teams need to evaluate several key technical and logistical factors that influence system reliability, performance, and long-term availability.

Purchasing an inappropriate CPU for industrial use may cause the system to fail, create thermal issues, or even lead to the unanticipated redesign of the product. Accordingly, it becomes necessary to understand the primary specifications and sourcing problems to ensure that a successful and scalable deployment takes place.

Clock Frequency and Core Effectiveness

The very first consideration during the sourcing of a CPU component is clock speed, generally speaking, this is measured in GHz. A CPU’s clock speed determines how quickly it can read and execute the code, which is of extreme importance in timely sensitive operations like real-time monitoring, robotics, or programmable logic controllers (PLCs).

However, it is important to note that just because a microprocessor has a higher clock rate does not mean it will always be the more efficient choice. The specific application workload must match up with the best core architecture. As an instance, if the industrial system is engaged in multi-threaded data analysis or running machine learning in the cloud, multi-core CPUs with parallel processing features will be the most efficient. On the other hand, it might be possible that in simple control tasks or in real-time collecting of sensor data, a CPU with high single-thread performance is more effective.

Properly aligning the CPU’s clock rate and core count with your application performance needs leads to optimal operation without overprovisioning, which, in turn, could cause additional heat and power consumption.

CPU Architecture and Instruction Set Support

Modern CPUs come in various architectures such as x86, ARM, and RISC-V, each offering distinct advantages. For CPU component sourcing, selecting the appropriate architecture is critical to software compatibility, power efficiency, and development scalability.

Industrial applications that run Windows or full Linux distributions often require x86-based CPUs, especially when interfacing with legacy software or specialized drivers. On the other hand, ARM-based CPUs dominate in low-power and embedded systems due to their efficiency and increasingly robust processing capabilities.

A prior step is to check the suitability of your preferred architecture with the required instruction sets, virtualization features, and real-time operating system compatibility before purchase. Getting this cooperation done at the very beginning of the CPU component sourcing process can eliminate the chances of development and firmware incompatibilities.

The Thermal Profiles and Environmental Tolerance column features

Industrial environments address specific challenges, including high ambient temperatures, vibration, and oblique air circulation. Therefore, a CPU’s thermal design power (TDP) and overall thermal profile should be configured in such a way as to match the deployment conditions of the system.

Low-power CPUs with under 15W TDP are the best fit for fanless, sealed enclosures usually used in outdoors or hazardous places. While putting up a higher-TDP CPU usually will simply be in the heat, it will need additional thermal management solutions like a heat sink, fan, or even an active cooling system. The issue of thermal specifications in CPU component sourcing must be considered seriously. Always remember to look for industrial-grade CPUs that come with wide temperature ratings and the ability to operate sturdily under adverse conditions. A thermal tolerance mismatch can result in overlooked throttling, system instability, or hardware failure at an earlier date.

Sufficient Duration of Supply and Lifecycle Support

The truth of so many facts is that one of the things that is least discussed-but crucial-to CPU component sourcing is long-term availability. For example, many industrial systems have a life span of 7-15 years (or more) while the time for consumer products is usually shorter. For example, a CPU that is no longer in production after 2 years, making the whole thing defective, may lead to redesigning and software revalidation, which will cost a lot.

CPUs of the industrial-grade often come with lifecycle support and manuals that are extended. A few manufacturers make a 10+ year guarantee on the product availability, which assures OEMs that to can plan production and service with a lot of confidence. Identification of CPUs that you may use with stable roadmaps can be made with the help of trusted partners who work with a lot of such suppliers. If the supply chain stability is the priority, then a reliable supplier is a must. Major manufacturers utilize trusted suppliers for the purpose of ensuring secure CPU component sourcing without any surprises or grey market risks.

The Appropriate Anchor in Your Supply Network

A technical decision to make is not just when you choose a CPU-it is also a strategy for sourcing deals. Concerning CPU component sourcing, the distributors are the ones that manufacturers trust to provide not only the product knowledge but also guarantee availability. A dependable supplier becomes the anchor in your hardware supply chain that helps you to overcome lead times, EOL issues, and custom integration ones.

In addition, these partners furnish the route for technical solutions of tomorrow and facilitate global industry standards. Their help can make the difference between the surfacing of products without any hitches and redesigns in the last moment caused by unforeseen CPU shortages.

Wrap Up

The process of choosing the right CPU for industrial use is a multi-step one, though the most basic on it is looking at the performance benchmarks. Along with this, it is necessary to deeply understand the frequency of clock speed, compatibility of architecture, thermal limitations, and persistent availability. On the other hand, smart CPU component sourcing achieves having the right products available as scheduled and providing the right support during the whole system lifecycle.

For engineers, integrators, and procurement teams, working with an experienced and trusted sourcing partner offers the strategic advantage needed to build durable, high-performing industrial systems. In today’s competitive and often volatile supply chain environment, that kind of reliability is more important than ever.