Why Fiber Laser Marking Is Becoming Standard for Stainless Steel Products

Why Fiber Laser Marking Is Becoming Standard for Stainless Steel Products

Stainless steel parts are used almost everywhere. You can find them in medical tools, automotive systems, industrial equipment, and electrical cabinets. These parts often need clear markings. The marks are used for identification, tracking, or quality control.

In many factories across Europe and North America, fiber laser marking has become a common way to mark stainless steel. This change did not happen overnight. It came from real production needs and long-term use.

This article looks at why fiber laser marking works so well for stainless steel, how it is used in real applications, and what companies often learn after using it for some time.

Marking stainless steel is not as easy as it looks

At first glance, stainless steel may look like an easy material to mark. It has a smooth surface and good strength. But in practice, it can be challenging.

Stainless steel is hard and resistant to corrosion. These properties are great for products, but they also mean that some marking methods do not work well.

Ink can fade over time. Mechanical marking can leave stress marks or damage the surface. Chemical methods add extra steps and handling.

Because of these limits, many manufacturers started looking for a cleaner and more stable solution.

Why fiber laser marking fits stainless steel so well

Fiber laser marking does not touch the material. The laser beam changes the surface in a controlled way. This makes it easier to get consistent results.

From real production use, fiber laser marking offers several clear benefits:

- Marks stay readable for a long time

- No ink or chemicals are needed

- No direct contact with the part

- Little daily maintenance

- Stable results from batch to batch

These points matter more when marking is done every day, not just once in a while.

How fiber laser marking works on stainless steel

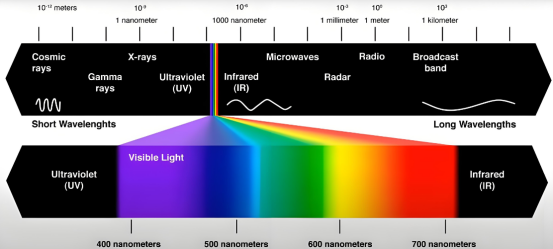

Most fiber laser systems use a 1064 nm wavelength. This wavelength works very well with metal materials.

By changing power and pulse settings, different marking effects can be created on stainless steel:

- Annealing marks that change color without engraving

- Dark marks with high contrast

- Light engraving for codes and numbers

This flexibility allows one machine to handle many marking tasks. It is one reason why fiber laser marking is widely used in industrial settings.

Common industries using fiber laser marking on stainless steel

In Europe and North America, stainless steel fiber laser marking is often used in:

- Medical devices that need permanent identification

- Automotive parts that must be traceable

- Electrical cabinets and control panels

- Valves, fittings, and industrial components

- Metal nameplates and labels

In these industries, markings are not only for appearance. They are often checked during audits or inspections. If the mark fades or becomes unreadable, it can cause problems later.

What many users learn after switching to fiber laser marking

Companies that move from ink or mechanical marking to fiber laser often notice changes after some time.

One common point is consistency. Once the marking parameters are set, the result stays the same. There is less variation between operators or shifts.

Another point is maintenance. There is no ink to refill and fewer parts that wear out. This helps reduce downtime.

Many users also find that fiber laser marking fits better into automated production lines. It is easier to connect with software systems and data tracking tools.

Laser power: more is not always better

A common mistake is to think that higher laser power always gives better results. In reality, this depends on the application.

For many stainless steel parts:

- 20W to 30W fiber lasers are enough for text, logos, and QR codes

- Higher power is mainly used for deeper engraving or faster cycles

Choosing the right power level helps keep the marking clean and avoids unnecessary heat on the part.

Why fiber laser marking supports traceability

Traceability is important in many industries. Parts often need serial numbers, batch codes, or QR codes.

Fiber laser marking can produce sharp and readable codes, even on small stainless steel parts. These codes can stay readable for years.

This is one reason why fiber laser marking is often used in regulated industries, where clear identification is required.

Comparing fiber laser marking with other methods

Many marking methods can be used on stainless steel, but they do not all offer the same results.

Ink printing is fast, but the marks can fade. Mechanical marking is permanent, but it can damage the surface. Chemical methods add extra steps.

Fiber laser marking balances marking quality and long-term stability. This balance is why it is often chosen for stainless steel products.

Long-term value in daily production

In daily production, small issues can add up. Ink refills, tool wear, and cleaning all take time.

Fiber laser marking reduces many of these issues. Once installed and set up, the system can run with little adjustment.

For manufacturers that mark stainless steel parts every day, this stability has long-term value.

Learning more about fiber laser marking systems

Fiber laser marking is not a one-size-fits-all solution. Different applications need different settings and system designs.

For companies that want to explore stainless steel fiber laser marking systems in more detail, technical resources and application examples are often available from professional manufacturers and industry suppliers.