How Advanced Composites Are Quietly Reshaping Modern Engineering

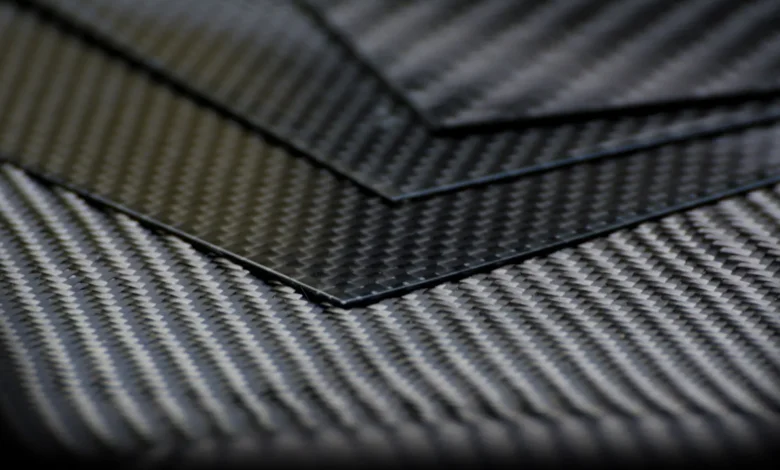

Across defence, transport, and critical infrastructure, a quiet shift is underway from metal- heavy designs to smarter composite structures that do more with less. Engineers, procurement teams, and policymakers are under pressure to deliver systems that are lighter, tougher, and more efficient without sacrificing safety or performance. This is where advanced fibre‑reinforced materials have stepped out of the lab and into front‑line roles, from aircraft panels and radomes to vehicle armour and unmanned systems.

What makes this moment different is the convergence of three forces: rising demand for resilient supply chains, tighter sustainability expectations, and rapid advances in digital engineering. Together, they are reshaping how composites are designed, sourced, and manufactured, and they are changing what organisations expect from their material partners.

From metal mindset to material strategy

For decades, metals were the default choice in demanding environments because they were familiar, certifiable, and widely available. Today, that mindset is being replaced by a more strategic one.

- Design teams increasingly start with performance outcomes – range, survivability, stealth, lifecycle cost – and then work backwards to the material stack that can deliver them.

- Composite layups, fibre orientations, and resin systems can be tuned to local loads, impact zones, or thermal hotspots in ways that standard metal plates never allowed.

- This shift also changes how risk is shared. Instead of buying “raw” material and doing all the engineering in‑house, many organisations now lean on specialist partners to co‑design and validate critical components.

The result is not just lighter parts, but systems that are engineered from the outset around the strengths and limitations of advanced composites rather than treating them as a

bolt‑on upgrade.

What actually happens on the factory floor

Behind every sleek composite structure is a surprisingly tactile blend of craft, automation, and process control. Even in highly regulated sectors, production is rarely a single monolithic method; it is a toolkit.

- High‑volume components might be produced using automated fibre placement, in which robots lay down tapes of reinforcement along precisely programmed paths to minimise waste and defects.

- Cylindrical or pressure‑bearing parts often rely on filament winding, in which fibres are tensioned and wrapped over mandrels at controlled angles to create exceptionally strong, repeatable structures.

- More complex shapes may still need skilled technicians to position preforms or fabrics by hand before curing, especially where geometry, access, or low volumes make full automation impractical.

Across all of these methods, the real differentiator is control: traceable material batches, tightly managed cure cycles, and rigorous inspection regimes that give end users confidence that every component will perform as modelled – not just on day one, but after years of thermal cycles, vibration, and exposure.

The hidden challenge no one can ignore

For all their advantages, advanced composites introduce a difficult question: what happens at the end of life? Lightweight structures that last for decades are great in service but awkward when they finally come off the asset register.

- Traditional thermoset systems are notoriously hard to recycle, often ending up in

landfill or being down‑cycled into low‑value fillers.

- Organisations are starting to factor disposal and recyclability into their early design

trade‑offs, rather than treating them as someone else’s problem in 30 years.

This is where process innovation becomes as important as material innovation. New

approaches are emerging that recover fibres from cured parts, explore bio‑derived resins, and even design components with disassembly and reuse in mind. For teams used to thinking only in terms of certification and unit cost, that is a significant cultural shift – but one that aligns with broader environmental and regulatory trends.

In the middle of this transformation, carbon fiber manufacturing is becoming less about exotic one‑off parts and more about building dependable, traceable, and ultimately more circular material ecosystems.

What this means for people on the ground

If you work anywhere near engineering, operations, or procurement, this evolution in composites will probably reach your desk sooner than you expect. The practical implications are hard to ignore.

- Specifications will become more outcomes‑based, asking what performance

envelope is needed rather than which exact alloy or laminate should be used.

- Collaboration across disciplines – design, analysis, manufacturing, logistics, and sustainability – will tighten, because the trade‑offs live at the intersections.

- Skills will shift: teams will still need traditional fabrication and machining expertise, but they will also need people comfortable with data‑driven process control, digital twins, and non‑destructive evaluation.

The organisations that adapt fastest will likely be those that treat composites not as a niche speciality but as part of a broader move toward smarter, more resilient engineering. For everyone else, the choice is becoming starker: either keep bending metal as usual, or learn to speak the new language of materials that are stronger, lighter, and – increasingly – smarter by design.