Introduction of JUSTWAY’s website Services

In this world, product development is growing rapidly, with companies and customers finding reliable partners that convert engineering ideas into reality and manufacture products. Justway has been introduced as a prominent brand in this field that provides a platform for custom manufacturing services, such as 3D printing, CNC machining, sheet metal fabrication, injection molding, and more. With advanced tools, global reach, and client-based workflows, JUSTWAY provides innovators, engineers, and businesses the ability to accelerate their product development duration from prototype to production.

What Is JUSTWAY?

Justway is a technology-based custom manufacturing service provider that helps engineers, startups, and designers and comes with a team for generating accurate parts and prototypes on demand.

Working through the online portal Justway.com, the company has combinations for advanced manufacturing features for a user-friendly ordering platform that helps users all over the world upload design files, get instant quotes, and track orders in real time.

Either you needed a high-accuracy prototype or batch production-ready components. Justway Services also fulfills manufacturing demands through high accuracy and competitive pricing.

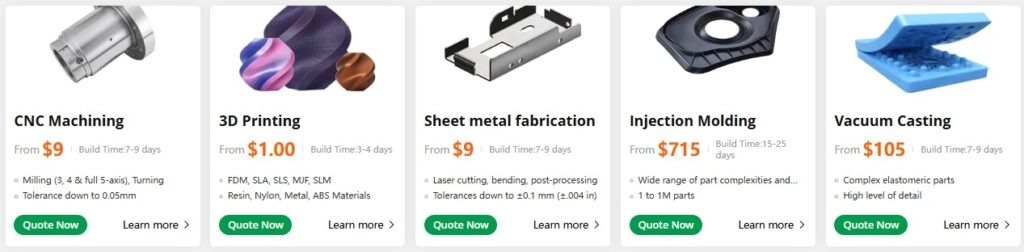

Core Services Offered by JUSTWAY

JUSTWAY’s portfolio manages different manufacturing processes, each designed for serving different phases of product development and differing technical requirements. Below are the main services available:

CNC Machining Services

CNC (Computer Numerical Control) machining is important for high manufacturing services; Justway offers complete CNC features for making complicated designs with high accuracy.

Types of Machining:

- Milling, turning, and metal cutting are common machining.

Materials Supported:

- Different metals like aluminum, brass, copper, titanium, and high-performance engineering plastics.

Typical Applications:

- normal functional prototype, high-accuracy housing and frames, vehicle components, etc.

Benefits:

- tight tolerance down to 0.05 mm, good surface finishing, and proper management for one-off prototypes and small batch runs.

CNC machining is best for high strength, accuracy for dimensions, and preparation for the design’s performance, making it important for industries like aerospace, medical, robotics, and consumer products.

3D Printing & Additive Manufacturing

3D printing provides early design validations and prototype testing, especially for handling complicated designs or layouts that are high cost and difficult to make through traditional approaches.

JUSTWAY supported a different range of additive manufacturing processes and materials:

- Methods: FDM, SLA, SLS, MJF, and SLM

- Materials: From PLA and ABS plastics to engineering nylon and metal powders like stainless steel or aluminum.

Applications

- Functional prototypes for testing operations

- Display rules for design review or exhibitions

- Small series parts with complicated geometries

- End-use components where traditional tooling would not be cost-effective.

With 3D printing, engineers can get models in some days, speeding up products during product development.

Sheet Metal Fabrication

sheet metal used for enclosures, brackets, chassis, electronics manufacturing tools, and industrial applications.

JUSTWAY’s sheet metal services include:

- Laser cutting

- Bending and forming

- Post-processing finishes

These processes help high-precision components that fulfill structural requirements with controlled tolerances.

Injection Molding

Injection molding is a technique for making larger plastic components effectively.

- JUSTWAY offers injection molding with tool features and production operations from single pieces to millions of parts.

- This process is best for durable consumer cases, mechanical housings, user device components, and the same parts used in commercial products.

Injection molding is one of the most cost-effective bulk production techniques once tooling is defined and provides high repeatability and good surface quality.

Vacuum Casting & Urethane Casting

- For low-volume manufacturing runs through plastic or elastomeric components that show final manufacturing materials, vacuum casting provides proper results without high tooling costs.

This service is useful when:

- Prototype testing needed final material characteristics

- Small batches are used before full production starts.

- Complicated components with soft-touch finishes or detailed features are used.

How JUSTWAY’s Platform Facilitates Manufacturing

One of JUSTWAY’s greatest modules is its online workflow, which accompanies customers from early concept to delivery.

Design Upload & Instant Quoting

Users can upload standard CAD formats and get instant costs based on material, process, and quantity, reducing conventional quote turnaround times that can take days or weeks.

Design for Manufacturability (DFM) Feedback

JUSTWAY provides design for manufacturability details to help optimize components before manufacturing, lowering costs and improving mechanical quality.

Online Production Tracking

The platform provides real-time tracking features, giving an overview into production stages from order confirmation to moving to manufacturing and shipment. This transparency helps engineers plan their working schedules and provide delivery timelines with confidence.

Quality Assurance & Support

JUSTWAY maintains quality control across processes, which helps in its high customer reviews and quality ratings. Customer feedback often provides precision, communication, and reliability as strengths of the service.

Industries and Use Cases Served

JUSTWAY’s manufacturing features make it best for different sectors, such as:

- Automotive & Transportation

- Functional engine and structural parts

- Aerospace & Aviation

- High-precision components with strong tolerances

- Medical Devices

- Biocompatible prototypes and friendly manufacturing

- Consumer Electronics

- Complicated housings and accessories

- Industrial Machinery & Robotics

- Durable structural components and rapid prototyping support

Conclusion

JUSTWAY stands at the best of digital manufacturing and global engineering services, offering an accessible, high-quality route between design concepts and finished products. With a full spectrum of services, from CNC machining and sheet metal fabrication to 3D printing and injection molding, JUSTWAY caters to innovators, startups, and global corporations. Its online platform simplifies the ordering, quoting, and manufacturing process, helping customers deliver ideas forward with speed and precision accuracy.